Combined damping ballast bed suitable for high-performance damping requirements of urban rail transit

An urban rail transit, high-performance technology, applied in the field of combined vibration-damping track beds, can solve problems such as single product, high investment in vibration-damping track-bed engineering, and structural vibration-damping performance that cannot meet design requirements, and achieves a high degree of generalization and vibration reduction. The performance is easy to guarantee, and the effect of splitting is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

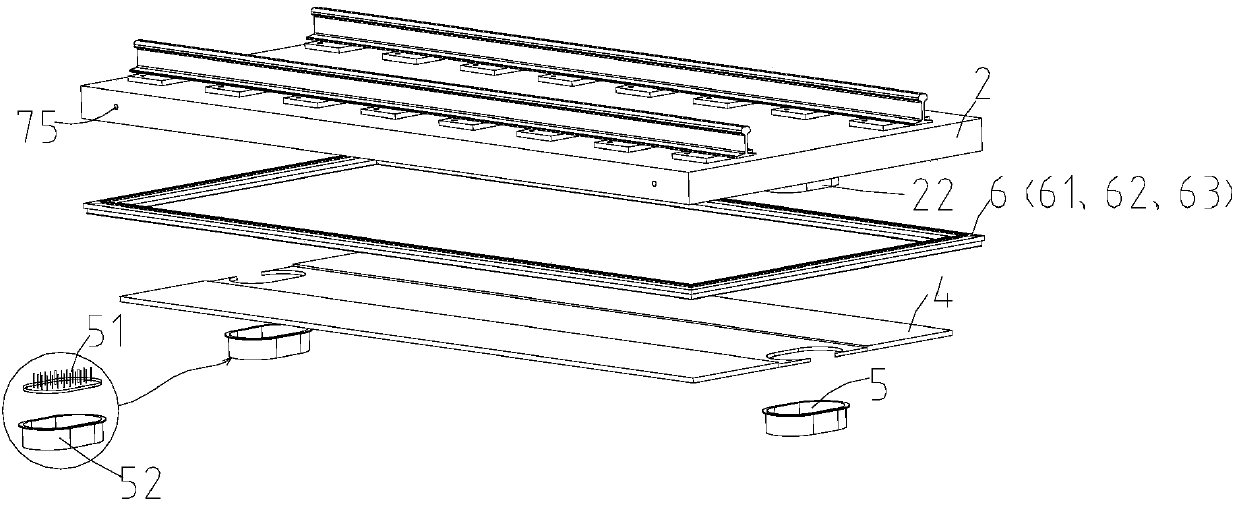

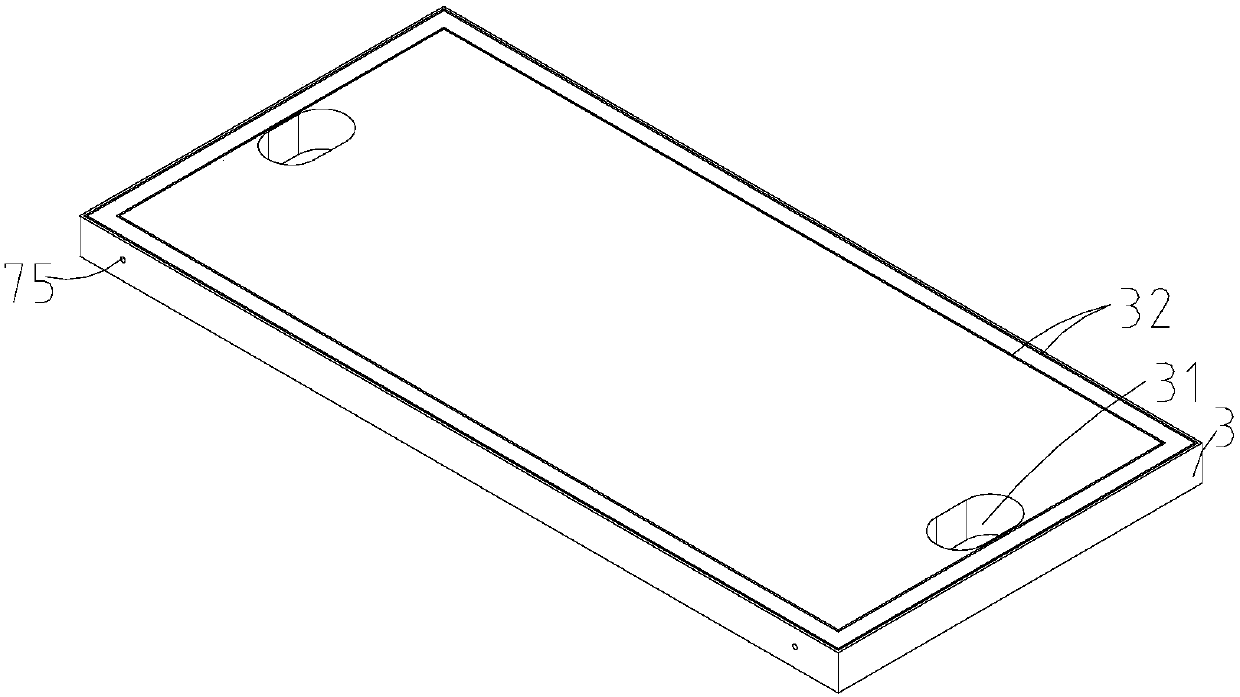

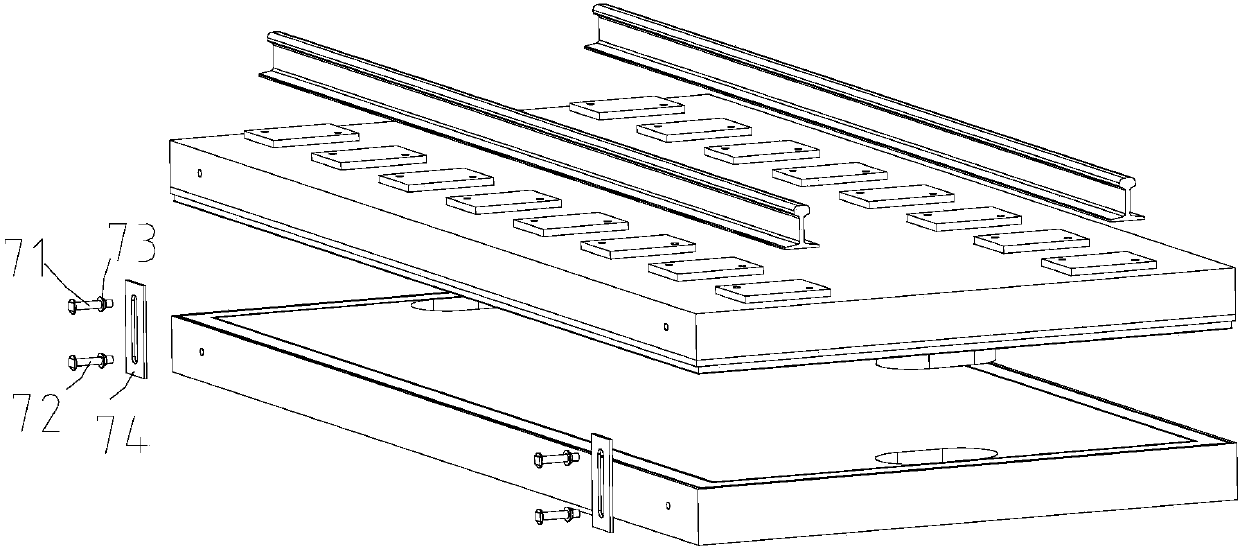

[0045] Such as figure 1As shown, the present invention includes a prefabricated track bed 2, a prefabricated base plate 3, a vibration damping pad 4, an elastic boot 5, a water stop 6 and a clamp 7, and the main body of the combined damping track bed 1 is composed of a prefabricated track bed 2, a vibration damping Pad 4 and prefabricated base plate 3 are stacked from top to bottom to form a packaging structure. Vibration-absorbing pad 4, elastic boots 5, and waterstop 6 are all placed between prefabricated track bed 2 and prefabricated base plate 3, and the water stop The belt 6 surrounds the vibration damping pad 4 and lays along the peripheral edges of the prefabricated road bed 2 and the prefabricated base plate 3, so that the vibration damping pad 4 and the water stop belt 6 are formed between the precast road bed 2 and the prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com