Prefabricated concrete dense rib truss reinforced steel bar thermal insulation box type component

A technology of prefabricated concrete and concrete, which is applied in the direction of underwater structures, building structures, infrastructure engineering, etc. It can solve the problems of easy falling off, difficult transportation and hoisting, and self-heavy, so as to expand the application range, shorten the time, and reduce the weight. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

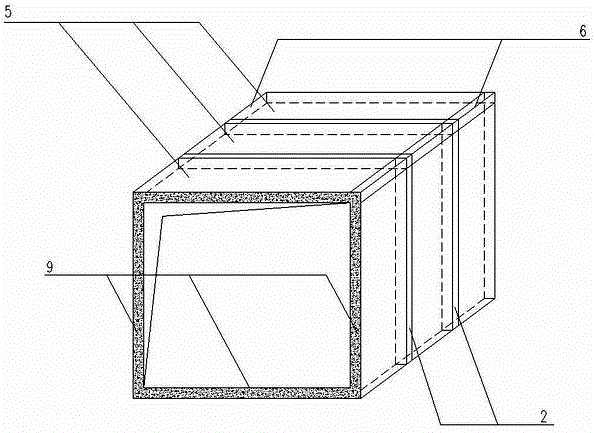

[0037] A prefabricated concrete densely ribbed truss reinforcement insulation box-shaped member, which includes a concrete slab enclosed by four sides, and forms a box-shaped structure. The internal structure of the concrete slab is a dense structure with truss reinforcement I1. ribbed concrete 2;

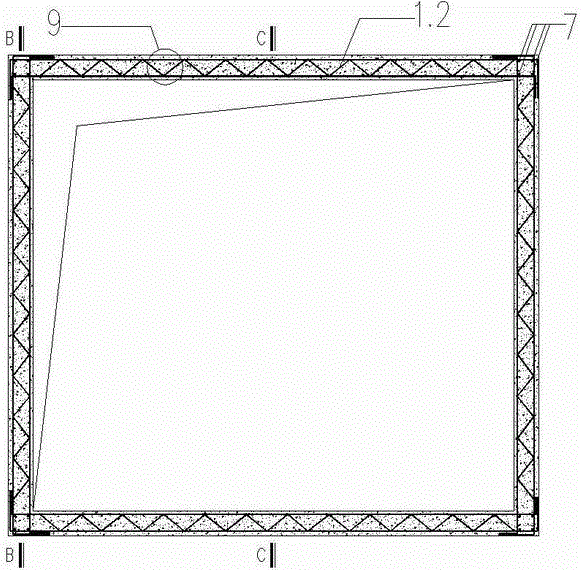

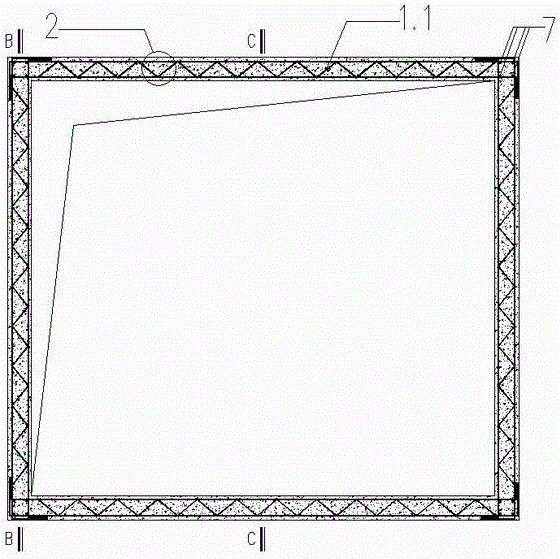

[0038] The dense ribbed concrete 2 and the upper and lower layers of thin-walled plate-shaped concrete 4 with steel wire flat mesh 3 form a honeycomb structure similar to a bent frame ( Figure 7 );

[0039] The truss reinforcement I1.1 and truss reinforcement II1.2 inside the ribbed concrete 2 are effectively lapped at the corners to enhance the integrity.

[0040] In the densely ribbed concrete 2, a number of vertical steel bars 7 and stirrups 8 are arranged inside the strip concrete 6 at the corner edge of the box-shaped member, which mainly function as frame beams.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com