Static crushing structure for removing concrete and construction method thereof

A concrete structure, static crushing technology, applied in building construction, building maintenance, erection/assembly of bridges, etc., can solve problems such as environmental impact, high cost, and many processes, and achieve an environment that saves construction time and reduces dust and noise. Pollution, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

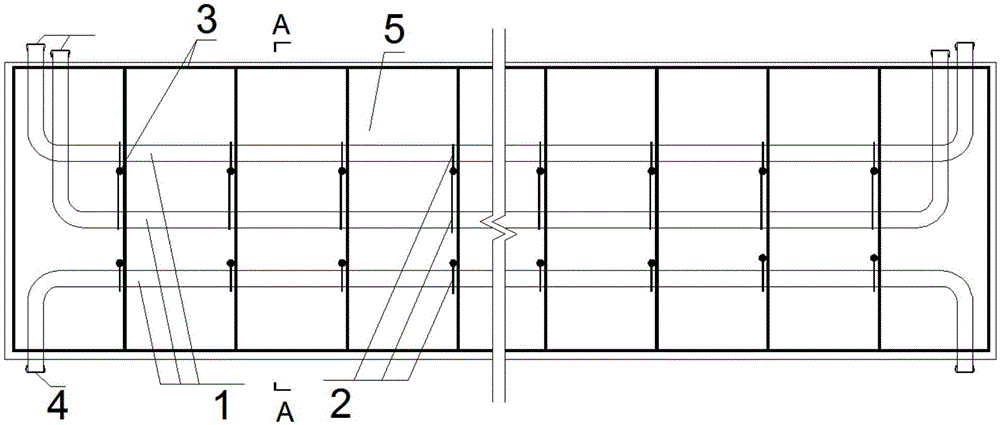

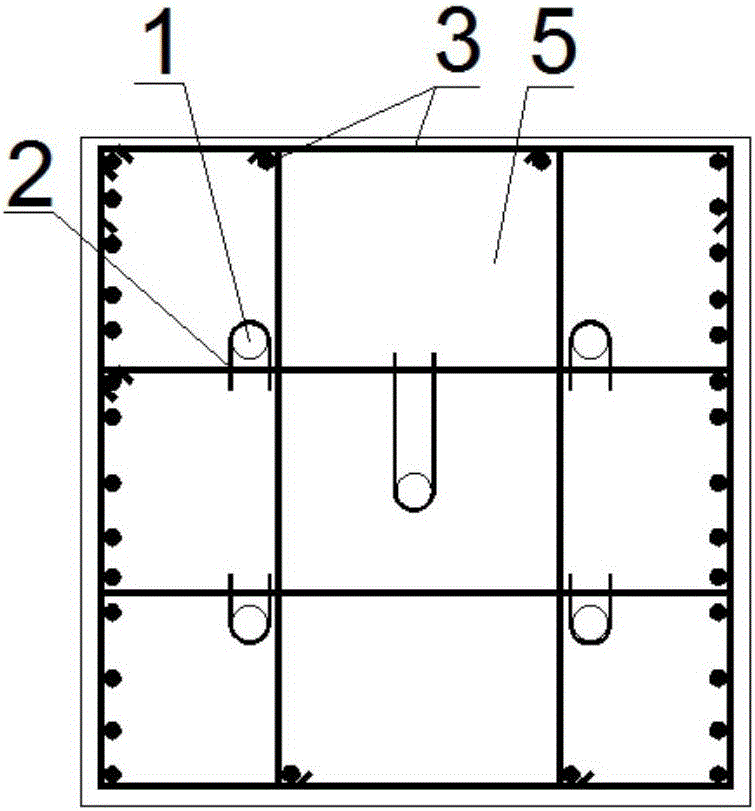

[0031] refer to Figure 1 to Figure 2 , this embodiment provides a static crushing structure for demolishing a concrete structure 5, including a concrete structure 5 and a steel structure 3 poured in the concrete structure 5, and also includes a pre-embedded pipe group embedded in the concrete structure 5 , the pre-embedded pipe group is composed of several pre-embedded pipes 1, and the nozzles of the pre-embedded pipes 1 expose the concrete structure 5. Since the pre-embedded pipe 1 is pre-embedded in the concrete structure 5, when the concrete structure 5 is removed, only the expansion agent needs to be poured into the pre-embedded pipe 1, and then water is added to rapidly expand the pre-embedded pipe 1. Under the action of the static force of expansion, the concrete structure 5 and the steel structure 3 will be peeled off slowly, thereby solving the problem of many static crushing procedures and high cost in the prior art. In addition, a static crushing structure for demo...

Embodiment 2

[0041] refer to Figure 1 to Figure 2 , the present embodiment provides a construction method for removing the static crushing structure of the concrete structure 5 as described in Embodiment 1, comprising the following steps:

[0042] Step 1: In the structural construction stage, the pre-embedded pipe group is arranged in the concrete structure 5 to be poured;

[0043] Step 2: In the structure construction stage, pouring concrete structure 5;

[0044] Step 3: In the stage of dismantling the structure, pour the expansion agent into the pre-embedded pipe 1;

[0045] Step 4: In the structure demolition stage, pour clean water into the pre-embedded pipe 1, so that the pre-embedded pipe 1 expands rapidly, and under the static force of expansion, the concrete structure 5 and the steel structure 3 begin to peel off;

[0046] Step 5: In the structure demolition stage, after the stripping of the concrete structure 5 and the steel structure 3 is completed, use a cutting machine to cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com