Subway station constructed by adopting rectangular jacking pipes combined with interval shields and construction method

A subway station, rectangular pipe jacking technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as inability to form departure/acceptance conditions, single form of subway stations, and difficult passage of shield tunnels, etc., to achieve guaranteed connection Reliability, flexible form, and construction cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

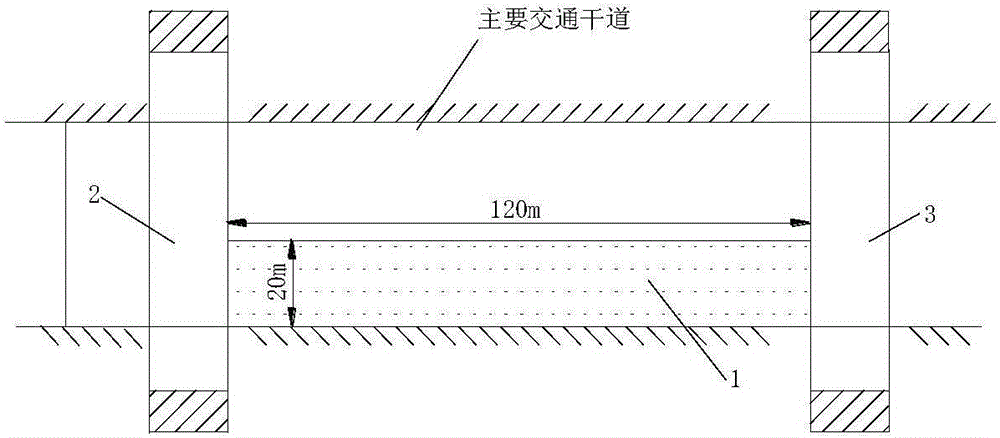

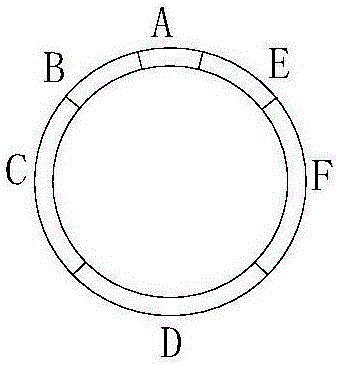

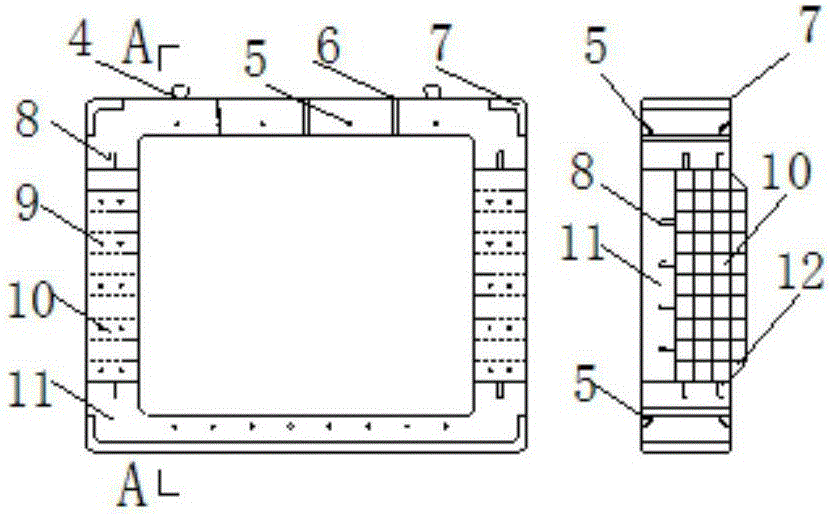

[0065] Such as Figure 1 to Figure 15 As shown, a subway station using rectangular pipe jacking combined with section shield construction, including the upper station and the lower station, some stations are assembled from multi-ring prefabricated components, and the adjacent prefabricated components of the same floor station have wedge-shaped grooves or wedge The wedge-shaped protrusion matched with the groove has a hand hole in the wedge-shaped groove or at the wedge-shaped protrusion, and the prefabricated components are connected through the hand hole through the bolt in the longitudinal direction.

[0066] The station includes the lower station and the upper station. The middle area of the lower station is connected with the upper station. There are platforms on the left and right sides of the lower station. The upper station is equipped with ground stairs connecting the upper and lower floors. The lower station is equipped with two escalators. The number of prefabricat...

Embodiment 2

[0079] A construction method for the installation of prefabricated segments in a subway station, the specific steps are as follows: see Figure 16(a)-Figure 16(d) , Figure 17 with Figure 18 as shown,

[0080] Step 1: If figure 1 As shown, before the construction of the subway station, the shield machine on the left line is carrying out the circular shield tunnel construction in the left end area of the lower station, and after continuously jacking the 5-ring prefabricated components, the axis is calibrated and the surrounding soil is reinforced by grouting; the right line The shield machine is used to carry out the construction of the circular shield tunnel at the right end of the lower station, and after every 5 rings of prefabricated components are continuously advanced, the axis is calibrated and the surrounding soil is reinforced by grouting;

[0081] Step 2: First, measure and determine the plane of the underground station to determine the planned location of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com