Ash cooling device for flat-plate cremation machine

A technology of cooling device and cremation machine, which is applied in the field of funeral services, can solve problems such as environmental pollution and inconvenient operation, and achieve the effect of simple control mode, simple installation, and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

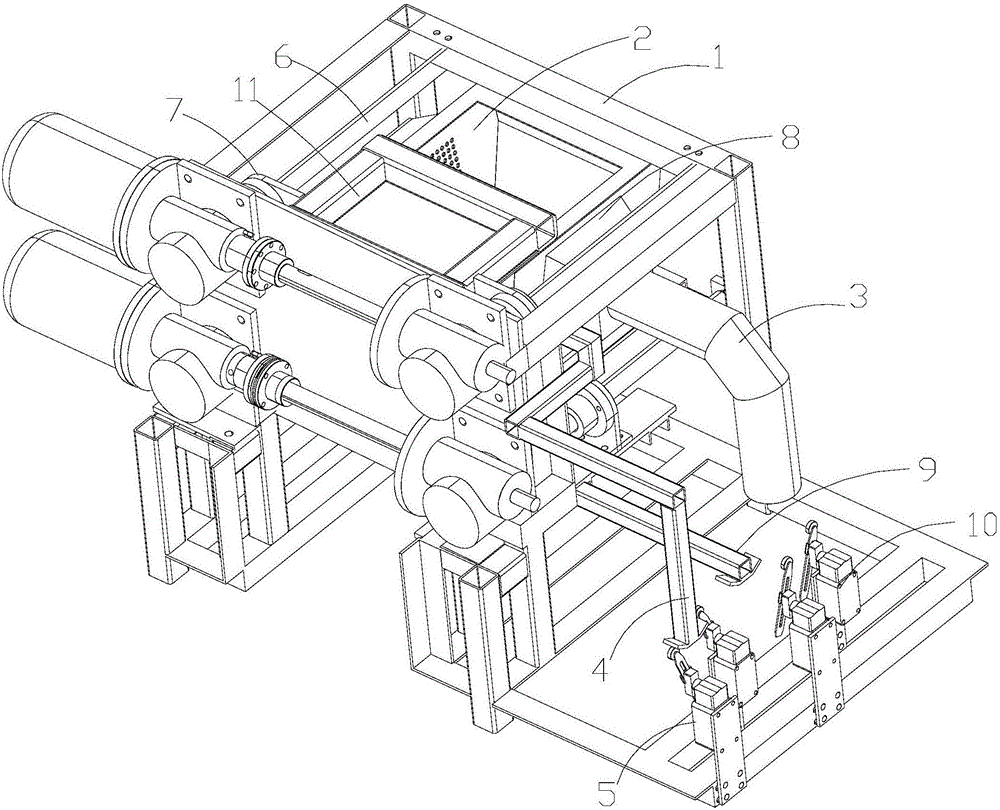

[0018] Such as figure 1 As shown, the present invention provides a ashes cooling device for a flat cremator. When the flat cremator is used for cremation, the pyrochemical industry uses tools to collect the ashes along the ash outlet in the furnace to the ashes cooling hopper. The upper sealing plate is closed. The cold air enters the ashes cooling hopper through the air inlet pipe from the air compressor. The ashes are cooled from above 500℃ to below 200℃ in about two minutes. The ashes cooling hopper is connected to the flue, and the ashes cooling hopper is always under negative pressure. It will not overflow and can be distributed into the flue. Therefore, the cooling rate is faster than natural cooling, will not pollute the environment, and will not burn fire and chemical industries.

[0019] The specific structure of the present invention includes a frame 1, on which is provided a ashes cooling hopper 2, the ashes cooling hopper 2 penetrates up and down to form a capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com