Electric Control Drainage Device for Steam Drying Cylinder

A technology of steam drying cylinder and electric control, applied in the field of textile dyeing and finishing, can solve the problems of increasing drying time, low energy utilization rate, increased drying cylinder self-weight, etc., and achieves improved hydrophobicity efficiency, improved steam utilization rate, and high measurement and control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

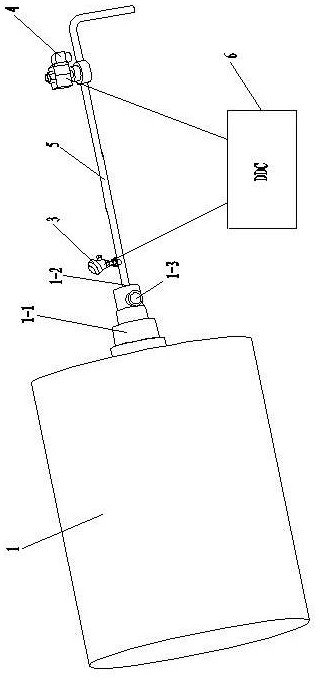

[0019] like figure 1 As shown, an electronically controlled hydrophobic device for a steam dryer includes a steam dryer 1, the steam dryer 1 includes a steam rotary joint 1-1, and the steam rotary joint 1-1 has a drain port 1-2 and a steam inlet 1 -3; the drain pipe 5 communicates with the drain port 1-2 of the steam rotary joint 1-1, and the drain pipe 5 is provided with a temperature transmitter 3 and a control valve 4, the temperature transmitter 3 It is electrically connected with the controller 6, and the control valve 4 is electrically connected with the controller 6 directly or indirectly.

[0020] The controller 6 of the present invention is a digital controller, or an industrial computer. When the control valve 4 is a solenoid valve, the control valve 4 is electrically connected to the controller 6 directly or indirectly. When the control valve 4 is a pneumatic valve, the control valve 4 is electrically connected to the controller 6 indirectly.

[0021] The working...

Embodiment 2

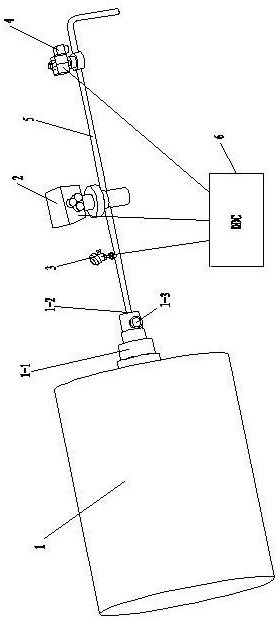

[0025] like figure 2 As shown, the difference between embodiment 2 and embodiment 1 is: an electronically controlled drainage device for a steam dryer, which also includes a water conductivity transmitter 2, and the water conductivity transmitter 2 is arranged on the drainage pipe 5 On the pipeline, and the water conductivity transmitter 2 is electrically connected with the controller 6. The water conductivity transmitter 2 is arranged between the temperature transmitter 3 and the control valve 4 on the pipeline of the drain pipe 5 .

[0026] The working process of embodiment 2: when the steam drying cylinder equipment is just started, the controller 6 controls the control valve 4 to open, and the steam enters the steam drying cylinder through the steam inlet 1-3 of the steam rotary joint 1-1, pushing air, etc. The non-condensable gas and condensed water are discharged through the drain pipe 5 and the control valve 4; the controller 6 receives the data detected by the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com