Cylinder body cylinder bore rabbet depth detection apparatus

A technology of depth inspection and cylinder block, which is applied in the direction of measuring device, mechanical measuring device, mechanical depth measurement, etc., can solve the problems that restrict the production efficiency of enterprises, fail to meet the process requirements, and not applicable to batch inspection, etc., so as to avoid long-distance transportation , reduce inspection time, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

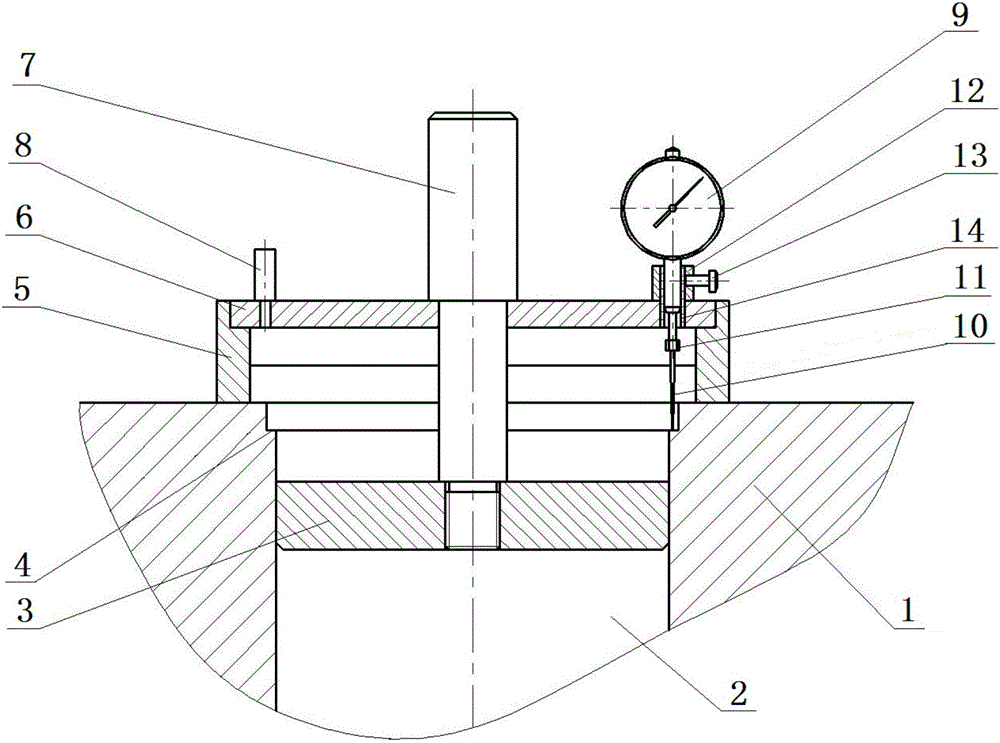

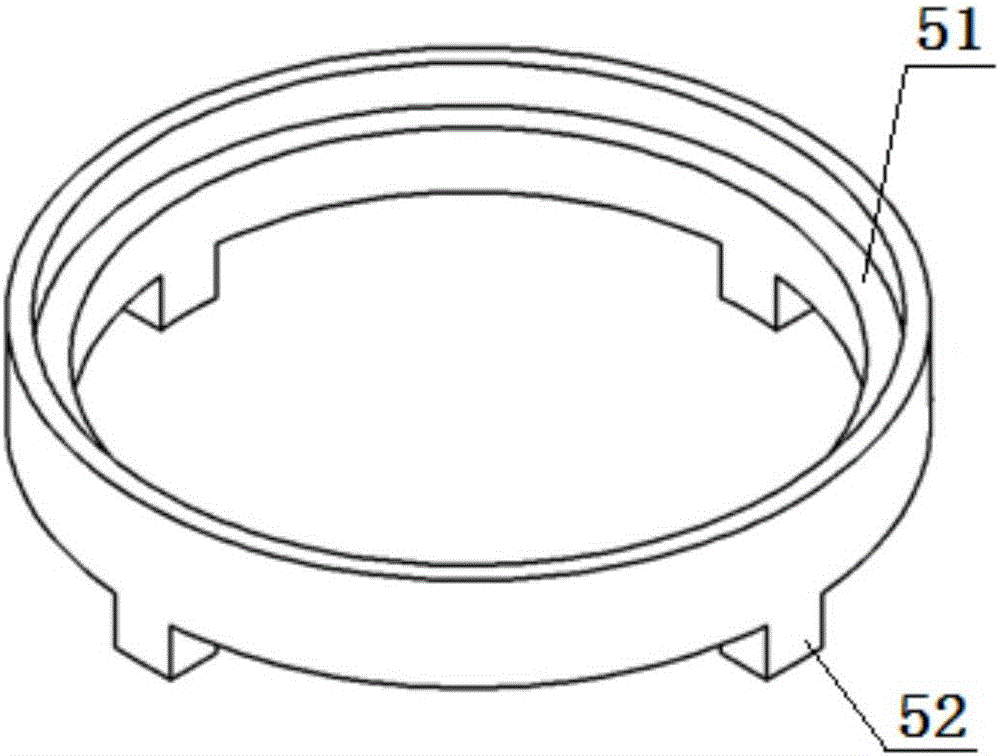

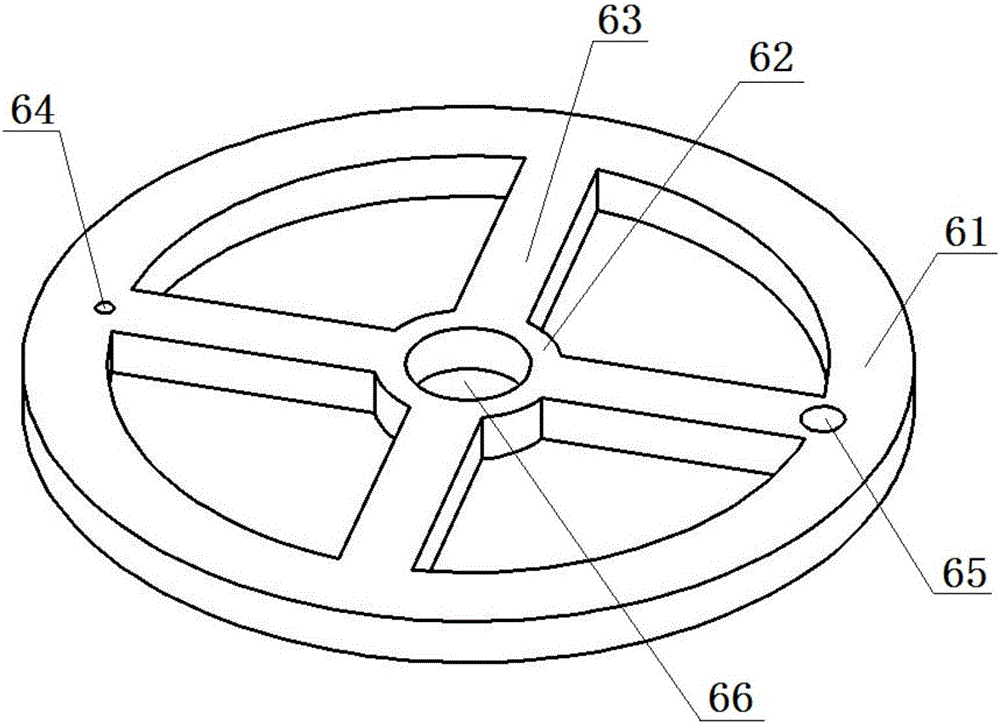

[0027] refer to Figure 1-5 , a cylinder bore spigot depth detection device of the present invention, comprising a flat cylindrical positioning block 3 matching the size of the cylinder bore 2 of the cylinder block 1, the positioning block 3 and the cylinder bore 2 of the cylinder block 1 There is a clearance fit between them, and a chamfer 32 is provided at one end of the positioning block 3 to facilitate the insertion of the positioning block 3 into the cylinder hole 2, and a thread for connecting the positioning block 3 is also provided at the center of the positioning block 3 Holes 31; above the positioning block 3, an annular base 5 with an outer diameter greater than the diameter of the mouth 4 of the cylinder block 1 is provided, and its inner diameter is greater than the diameter of the cylinder hole 2, and the base 5 is erected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com