Liquid-filled soil stress test device and test method

A technology of stress testing and stress, applied in measuring devices, force/torque/work measuring instruments, hydraulic/pneumatic force measurement, etc., can solve problems such as inability to test confining pressure, singleness, large deformation and cannot be accurately tested, and achieve Large soil deformation adaptability, the effect of accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

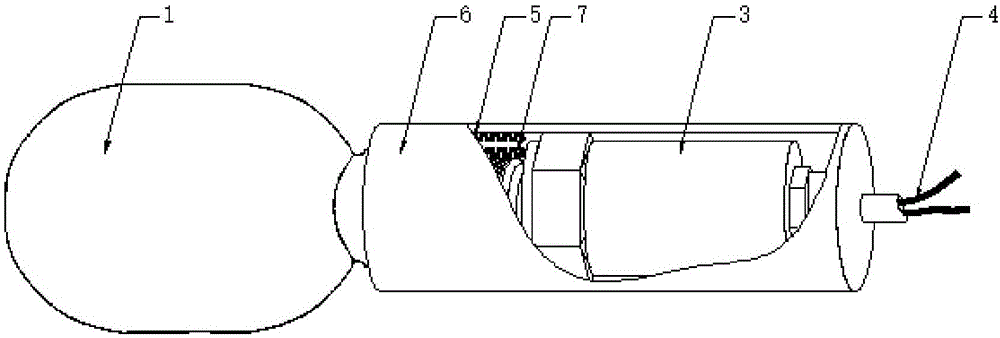

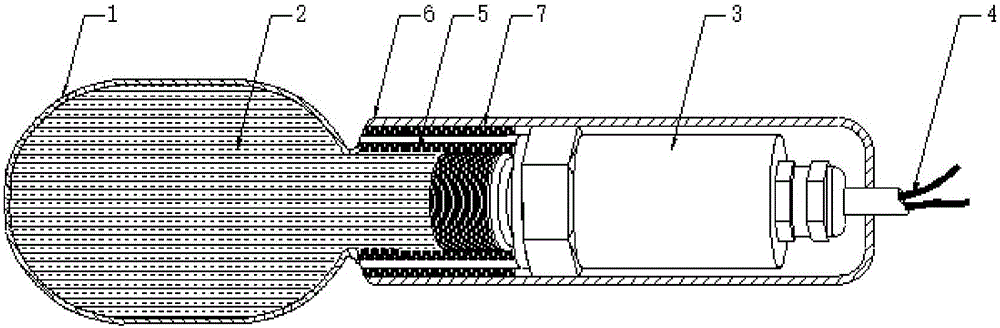

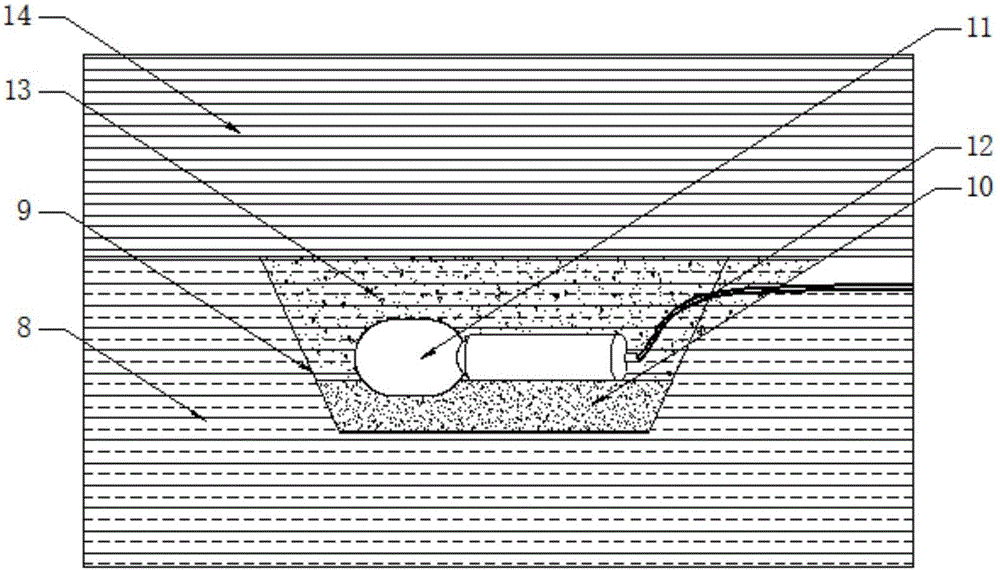

[0024] A liquid bladder soil stress testing device, comprising a bladder stress housing 1, a protection tube 6 and a transmission converter 3:

[0025] The bladder stress shell 1 is filled with a stress transmission medium 2, which is a liquid medium, and the contact surface between the bladder stress shell 1 and the soil is arc-shaped, which effectively solves the problem caused by the contact plane of the existing stress gauge. Unidirectional defects can contact the soil in all directions and fully sense the stress change of the unit soil; at the same time, the capsule stress shell 1 has strong elasticity and ductility, and can change shape with the deformation of the soil, effectively solving the problem. It overcomes the defect that the existing stress gauge is slightly deformed and cannot adapt to the large deformation of the soil, and the shelling phenomenon will not occur during use; the stress transmission medium 2 is in a liquid state, and no stress loss occurs during ...

Embodiment 2

[0027] In this embodiment, the transmission converter 3 is sealed and connected to the capsule stress shell 1 through the transmission converter connecting thread 5 . The remaining technical solutions of this embodiment are consistent with those of Embodiment 1, and the technical solutions adopted in this embodiment are also applicable to other embodiments.

Embodiment 3

[0029] In this embodiment, when the transmission converter 3 is connected to the capsule stress housing 1, it is sealed by a sealant. The remaining technical solutions of this embodiment are consistent with those of Embodiment 2, and the technical solutions adopted in this embodiment are also applicable to other embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com