Uncertainty Inverse Calculation Method of Oil Film Force and Oil Film Characteristics of Rotor Bearing

A technology of uncertainty and oil film characteristics, used in mechanical bearing testing, force/torque/work measuring instruments, instruments, etc., can solve the difficulty of identifying oil film characteristic parameters, affect the stability and accuracy of oil film characteristic parameter identification, and not consider Rotor bearing system uncertainty factors and other issues, to achieve the effect of improving efficiency and saving measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

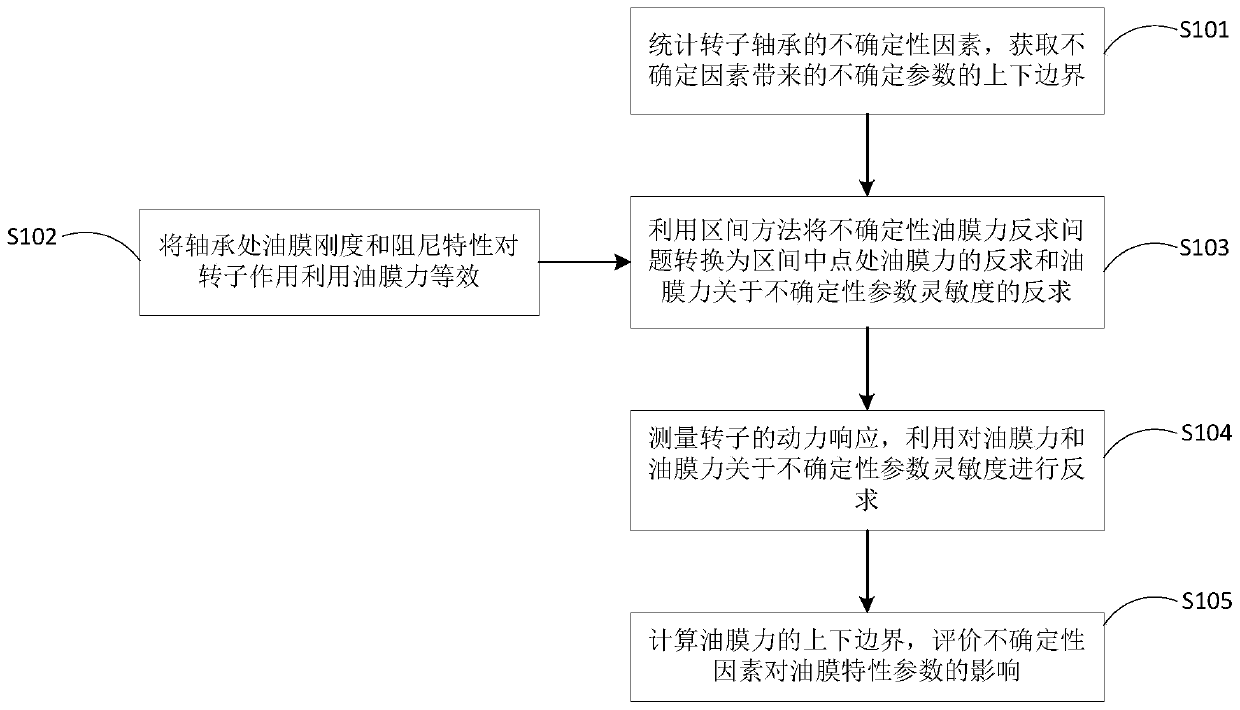

Method used

Image

Examples

Embodiment 1

[0035] Taking the unbalance amount caused by assembly error or thermal deformation during operation as an example with a certain level of uncertainty, the inverse calculation of the oil film force and oil film characteristic parameters of the rotor bearing is performed to describe the specific implementation of the present invention in detail.

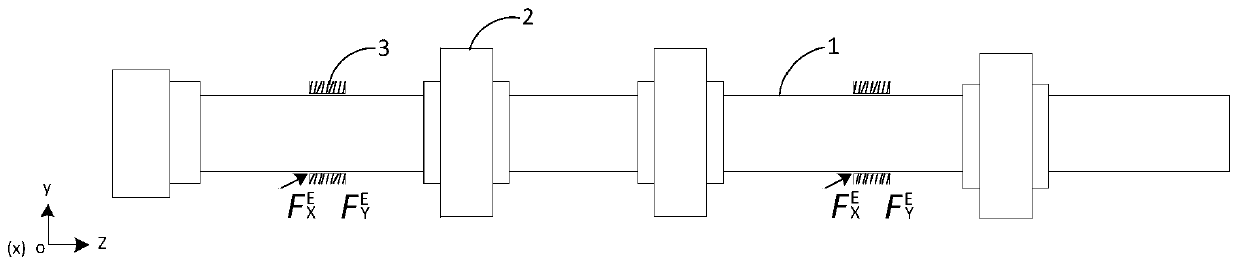

[0036] Step S101. According to the actual assembly error and the thermal deformation of the rotor bearing during operation, the uncertainty factors of the rotor unbalance are counted to obtain the upper and lower boundaries of the uncertainty parameters of the uncertainty factors. A schematic model of the rotor bearing system is shown in figure 2 As shown, three disks 2 and two bearings 3 are sleeved on the rotor 1, and the material density of the disk 2 is ρ=7.65×10 3 kg / m 3 , the unbalance is the eccentric mass of the middle disc 2, and the uncertain parameters are the eccentric mass m and the eccentric distance r. The upper and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com