Metal oxide anode life measuring device

A measuring device and oxide technology, applied in the direction of material electrochemical variables, etc., can solve the problems of low accuracy of metal oxide anode life test, achieve the effect of maintaining stability and uniformity, reducing manual intervention, and ensuring current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

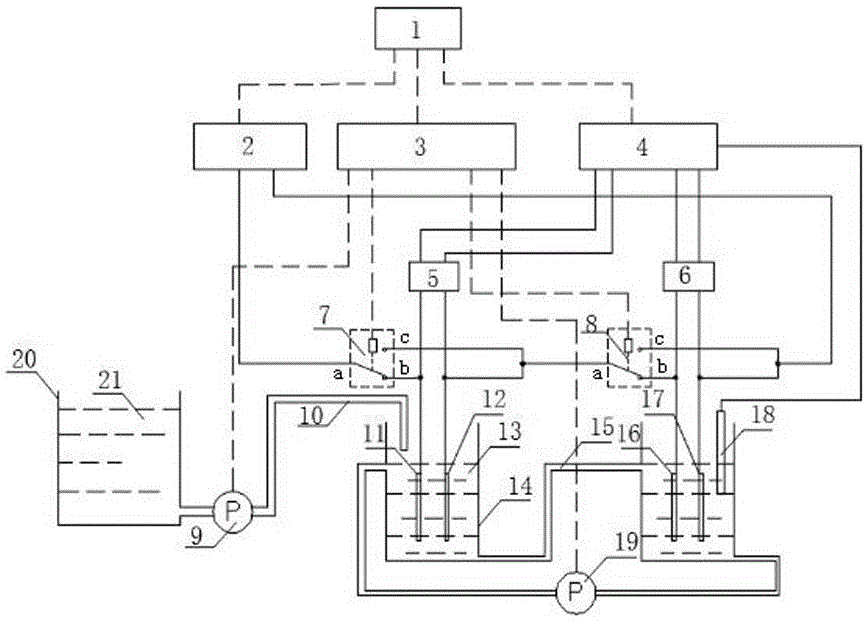

[0013] See figure 1 , An embodiment of the present invention (with two pairs of tested electrodes), a metal oxide anode life measurement device, including electrolysis power source 2, first metal oxide anode 11, first cathode 12, second metal oxide Material anode 16, second cathode 17, host computer 1, controller 3, data collector 4, first relay 7, second relay 8, metering pump 9, circulating pump 19, first signal conversion module 5 and second signal In the conversion module 6, each pair of cathodes and metal oxide anodes are respectively set in a sulfuric acid solution 3 in a sulfuric acid solution tank 14. The upper computer 1 is connected to the electrolysis power supply 2, the controller 3, and the data collector 4; the different control ends of the controller 3 are electrically connected to the controlled ends of the relays, the metering pump 9 and the circulating pump 19; the data collector 4 The data acquisition end of the signal conversion module is electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com