Submerged-arc furnace controller with low-pressure reactive compensation and electrode current control

A technology of electrode current and controller, applied in reactive power compensation, reactive power adjustment/elimination/compensation, furnace control device, etc., can solve problems such as lack of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

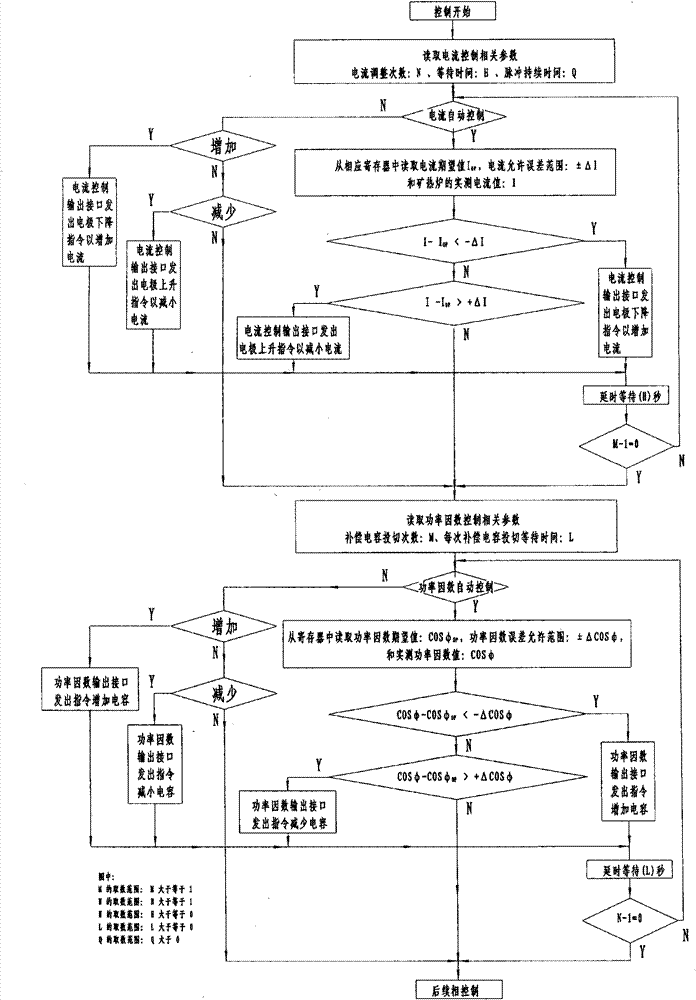

[0098] The invention relates to a submerged arc furnace controller with low-voltage reactive power compensation and electrode current control, which consists of two parts: controller hardware and control software. The relationship between them is: the control software controls and manipulates the controller hardware.

[0099] 1. Controller hardware:

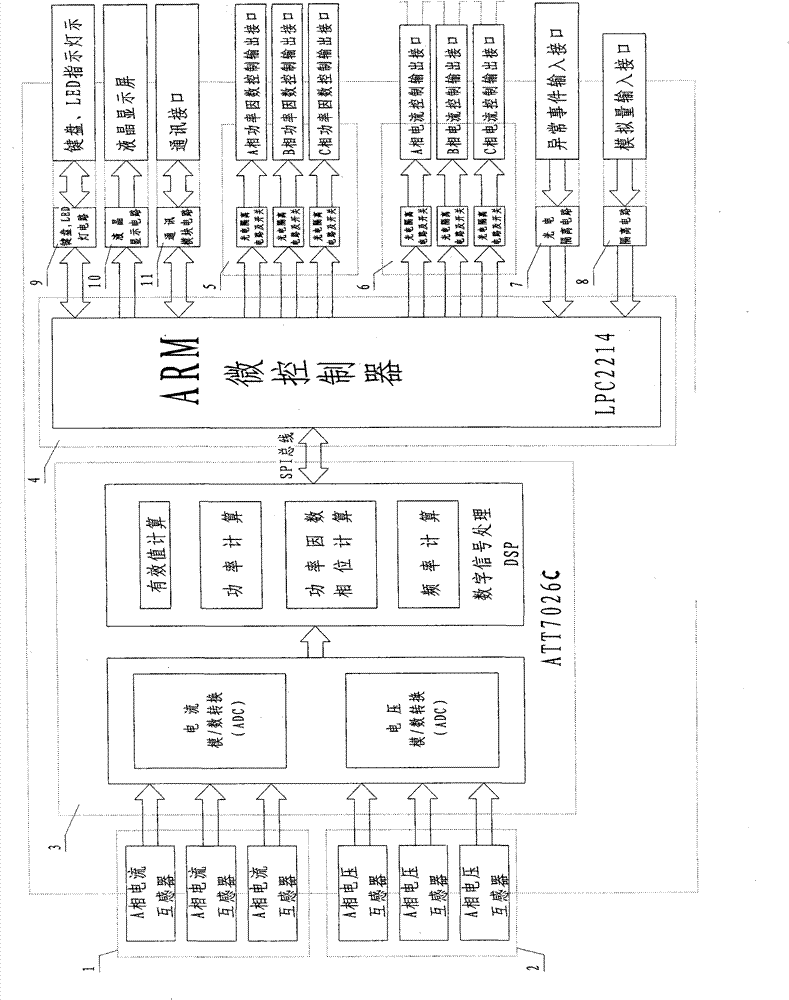

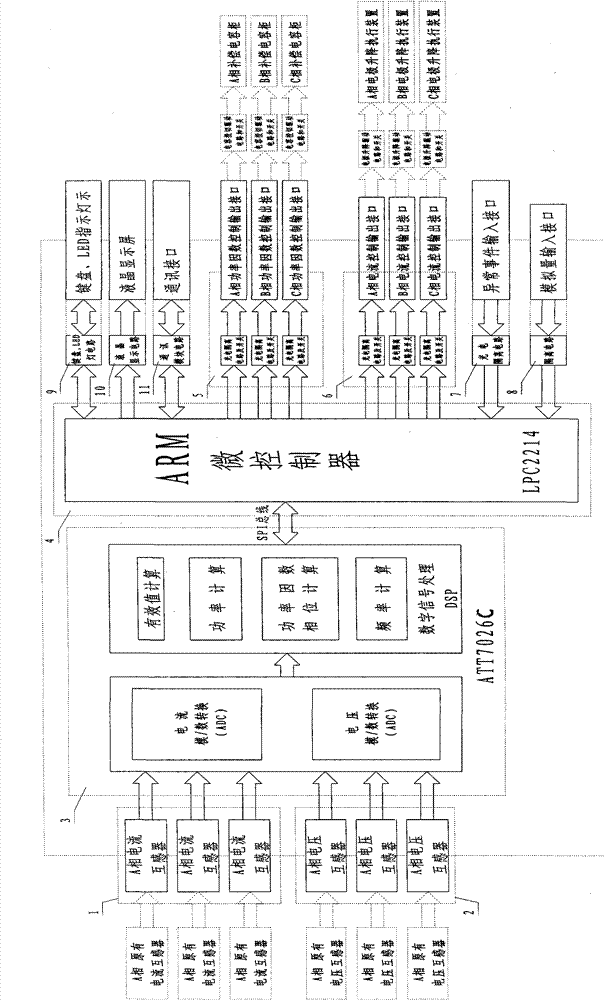

[0100] The principle block diagram of the controller of the present invention is as figure 1 shown.

[0101] (1), current transformer 1:

[0102] In the power transformer of the submerged arc furnace, its own current transformer is generally installed (we call it: the original current transformer), and its output value is to meet the needs of the instrument installed on the instrument console of the submerged arc furnace. , may not be able to meet the needs of the controller. In order to meet the needs of this controller, we set up the current transformers required by each phase in this controller. We call it: current trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com