Bar code printing tracing system

A barcode printing and traceability system technology, applied to record carriers, instruments, business and other directions used by machines, can solve the problems of low efficiency, low accuracy, brand building and after-sales cost loss of manual paper traceability, and improve after-sales Service quality, complete information collection, and the effect of promoting brand building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

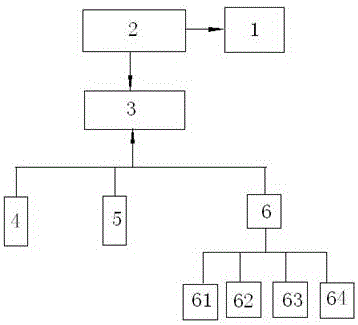

[0021] A barcode printing traceability system, comprising:

[0022] Retrospective inquiry module 1, described retrospective inquiry module 1 can carry out forward tracing and reverse inquiry;

[0023] Computer 2, described computer is equipped with supporting barcode printing traceability software and reverse query software, supports the forward traceability function and reverse query function of traceability query module 1 respectively;

[0024] A database 3, which includes an information collection module 4, a product barcode generation module 5 and a system processing module 6.

[0025] Wherein, the information collected by the data collection module 4 includes material / storage information, product process information, product inspection information, rework maintenance information and product packaging information; The scanning gun completes the information collection.

[0026] The product barcode generation module prints labels such as product two-dimensional codes and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com