Three-phase four-wire plug and socket plugging assembly

A plug socket, three-phase four-wire technology, applied in the field of three-phase four-wire plug socket assembly, can solve the problems of not being universally interchangeable, easy to generate arcs, easy to loosen plugs, etc., to achieve stability and reliability High, prevent dust from entering, contact is not easy to slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the structural representation of the present invention is described in further detail:

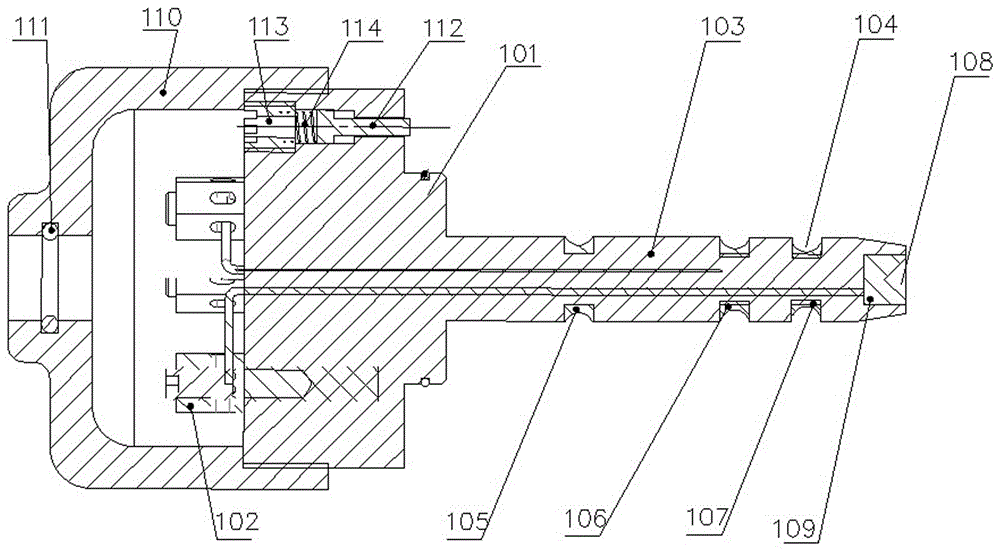

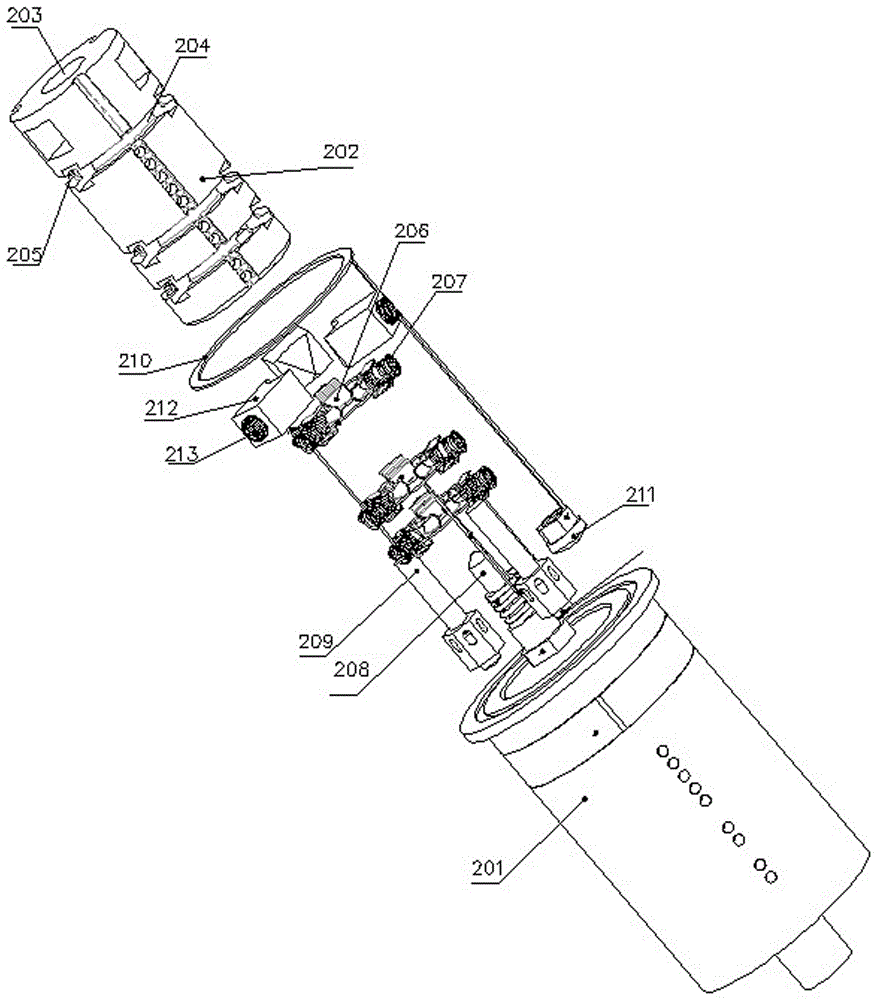

[0020] A three-phase four-wire plug socket assembly, including a plug assembly 1 and a socket assembly 2, the plug assembly includes a plug housing 101, and four male terminals are fixedly installed on the bottom surface of the plug housing 102, the top surface of the plug housing 101 is coaxially provided with a columnar plug body 103, and the plug body 103 is coaxially provided with three ring-shaped grooves 104, and the ring-shaped groove 104 is correspondingly installed with a concave ring-shaped zero line , U-phase, V-phase contacts 105, 106, 107, the head of the plug body 103 is provided with an indented groove 108, and a W-phase contact 109 is installed in the groove 108, and the head of the W-phase contact 109 is provided with a tapered hole; The four male terminals 102 are respectively connected to the corresponding contacts v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com