Optical module automatic temperature compensation device and control method thereof

A technology of a temperature compensation device and a control method, which is applied to lasers, laser parts, electrical components, etc., can solve the problems of time-consuming workload, poor flexibility, and failure of compensation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

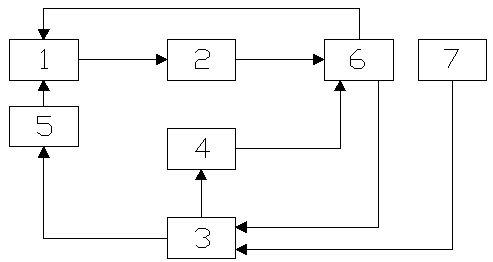

[0032] An optical module automatic temperature compensation device, the innovation of which is: the optical module automatic temperature compensation device consists of a comparator 1, a bias current adjustment module 2, a processing module 3, a modulation current control module 4, and a bias reference correction register 5 and Composed of a temperature sensor; the PD detector of the laser 6 in the optical module is connected to the comparator 1 and the processing module 3 respectively, and the processing module 3 is connected to the temperature sensor, the bias reference correction register 5 and the modulation current control module 4 respectively, and the bias reference correction The register 5 is connected to the comparator 1, the comparator 1 is connected to the bias current adjustment module 2, the modulation current control module 4 is connected to the modulation current input end of the laser 6, and the bias current adjustment module 2 is connected to the bias current i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com