Charging pile, charging system and charging control method

A charging pile and circuit technology, applied in charging stations, battery circuit devices, electric vehicle charging technology, etc., can solve the problems of large charging harmonic current and low power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

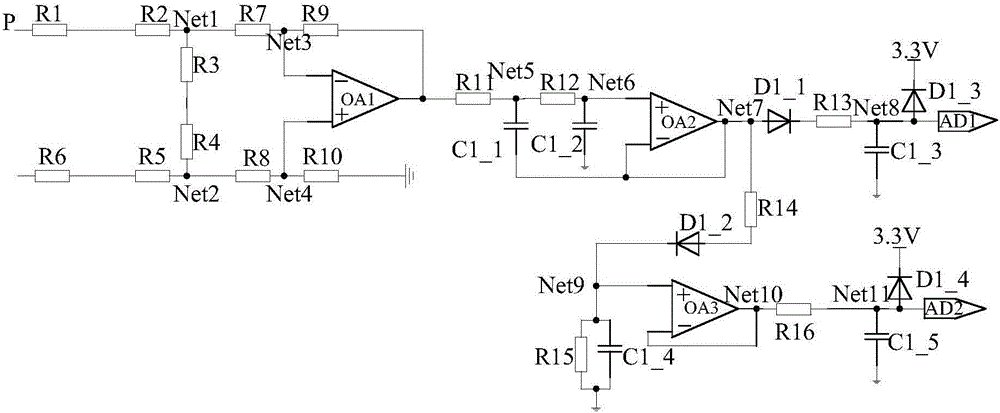

[0052] Embodiment 1 provides a charging pile, including a power conversion circuit and a sampling circuit. The sampling circuit is used to collect the voltage and current of a specific point in the power conversion circuit, and send it to the sampling port of the microprocessor to assist the microprocessor to realize the control of the charging process of the power conversion circuit.

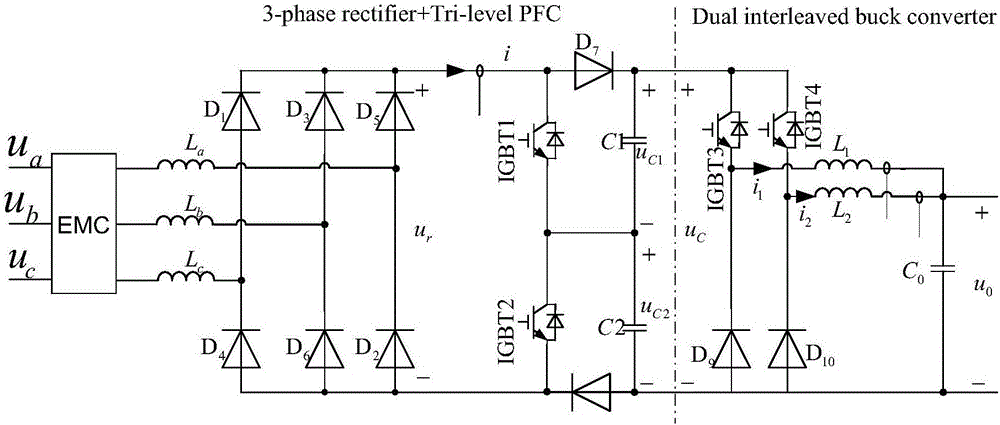

[0053] figure 1 A schematic circuit diagram of a power conversion circuit is shown. Such as figure 1 As shown, the power conversion circuit includes a three-phase three-level power factor corrector (hereinafter referred to as three-phase three-level PFC) and a double interleaved parallel step-down chopper converter (hereinafter referred to as a double interleaved parallel buck converter). What is described in the figure is a double interleaved parallel buck converter, and a triple interleaved parallel buck converter can also be used in actual use. The input end of the three-phase three-level...

Embodiment 2

[0074] Embodiment 2 provides a charging control method for a charging pile, the method includes the following steps:

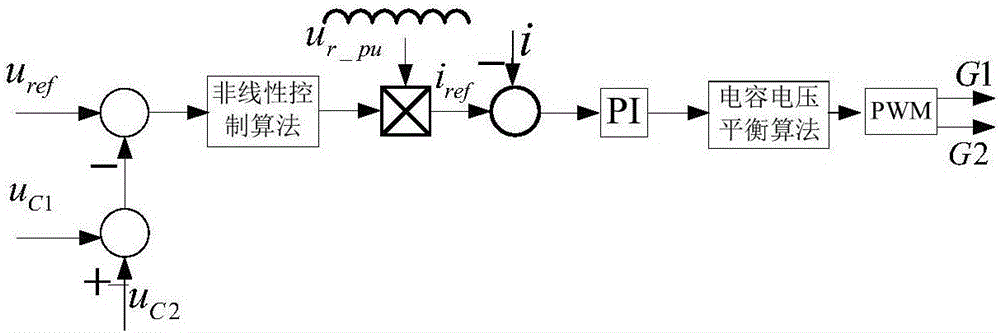

[0075] After the charging process starts, the microprocessor adopts nonlinear The proportional-integral control algorithm controls the output voltage of the three-level boost circuit to obtain the command current of the three-phase three-level power factor corrector;

[0076] The microprocessor calculates the duty ratio by using a linear proportional-integral control algorithm according to the command current of the three-phase three-level power factor corrector and the output current of the three-phase uncontrolled rectifier circuit collected by the sampling port;

[0077] The microprocessor adopts the midpoint balance algorithm to adjust the duty cycle, generates two switching signals, and uses the two switching signals to drive the three-phase three-level power factor corrector, so that the output voltage of the three-level boost circuit is constant ;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com