Laminated iron core, method for manufacturing laminated iron core, and punch for caulking formation used in the method

A manufacturing method and stacking direction technology, applied in the manufacture of inductors/transformers/magnets, stator/rotor bodies, magnetic cores/yokes, etc., can solve the problems of difficulty in forming V-stack rivets, deformation, cracks on the bottom surface, etc. Deformation prevention, excellent magnetic properties, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, embodiments for embodying the present invention will be described with reference to the drawings, so that the present invention can be understood.

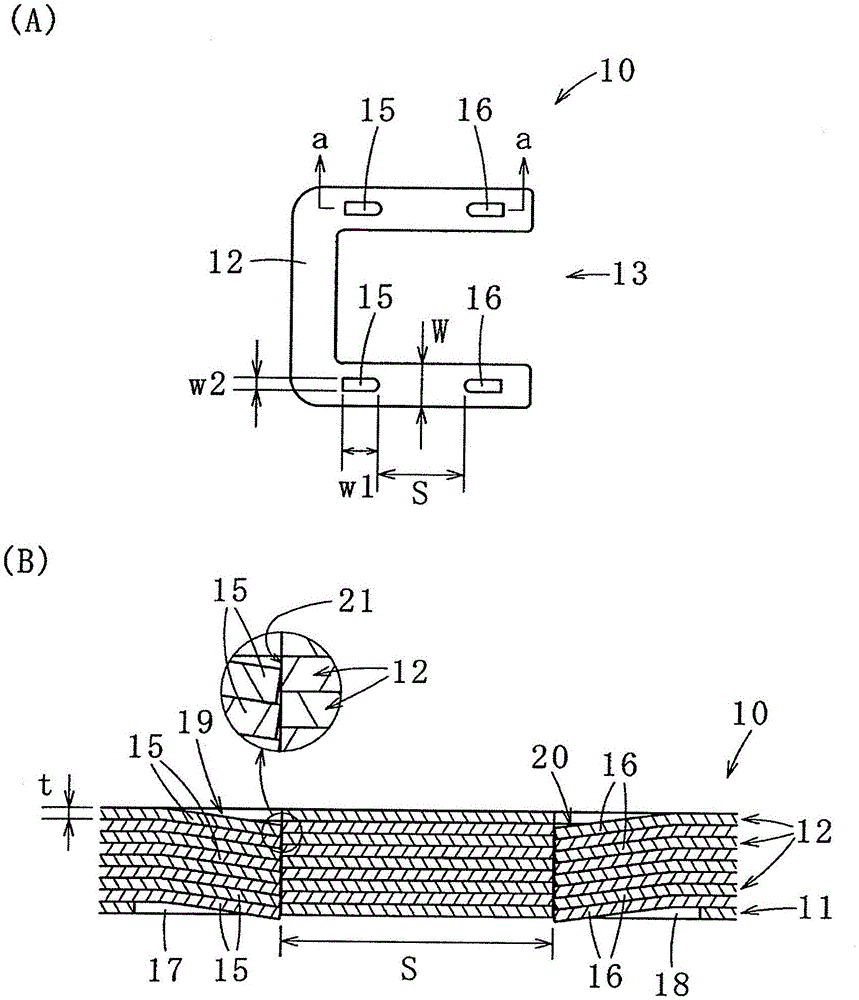

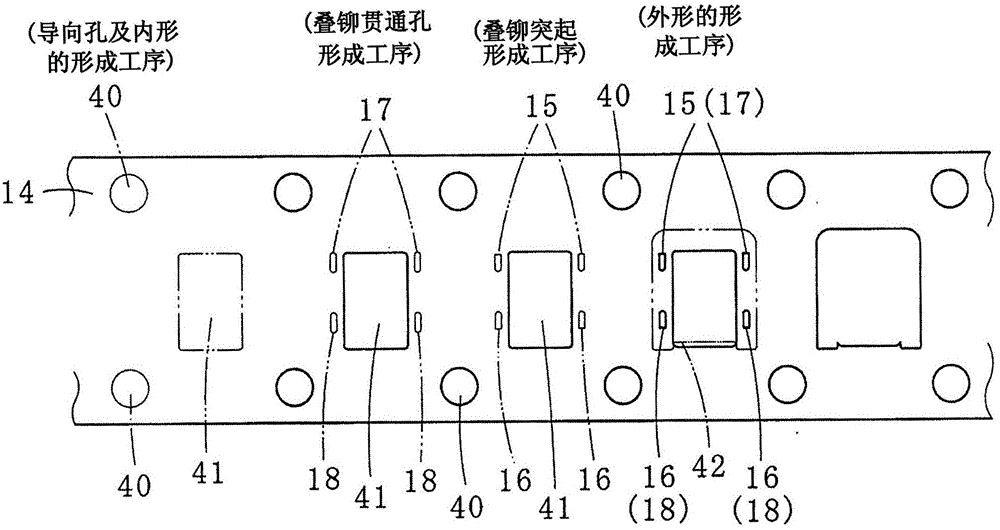

[0047] First, refer to figure 1 , figure 2 , the laminated iron core 10 according to one embodiment of the present invention will be described.

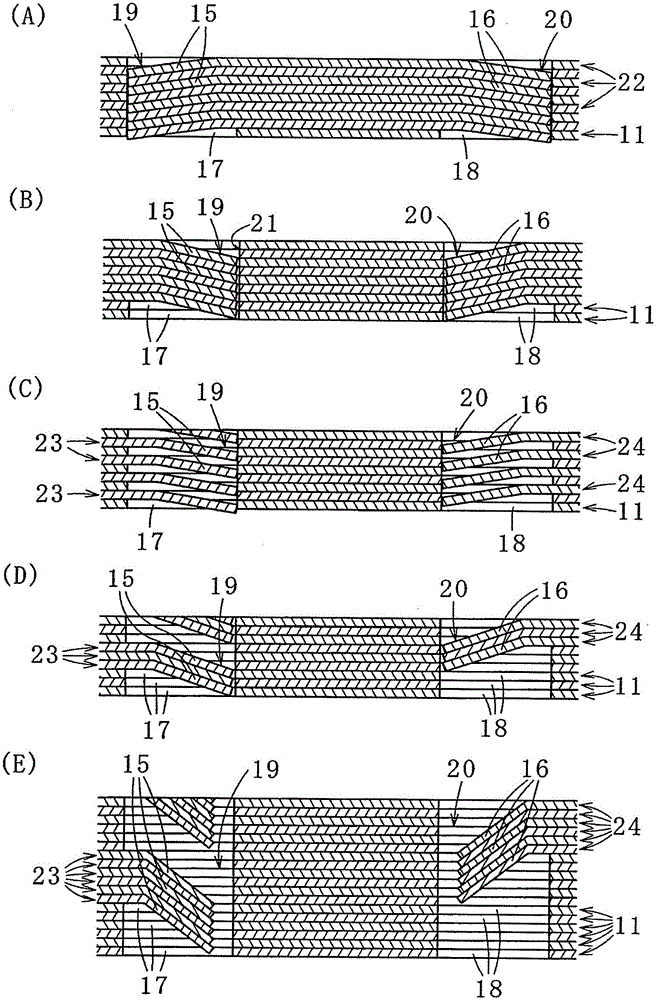

[0048] Such as figure 1 As shown in (A) and (B), the laminated iron core 10 is used for a motor, and is formed by laminating a plurality of core pieces 11 and 12 that are concave (U-shaped) in plan view. In addition, the shape of a core piece is not limited to this, It can change variously according to the kind of motor to manufacture (for example, the kind, size, etc. of a laminated core, hereinafter the same).

[0049] When using this laminated iron core 10, for example, four laminated iron cores 10 are arranged at the center of each side of an imaginary square in a plan view, and each laminated iron core 10 is directed toward the central position of the imaginary squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com