Vertical material conveying device for pasting and inserting machine

A feeding device and vertical technology, which is applied in the field of vertical feeding devices for placement and insertion machines, can solve the problems of no bending pins and cutting pins, improving market competitiveness, and large temporary space, etc., to achieve operation and use. Convenience, improving market competitiveness, and small temporary space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

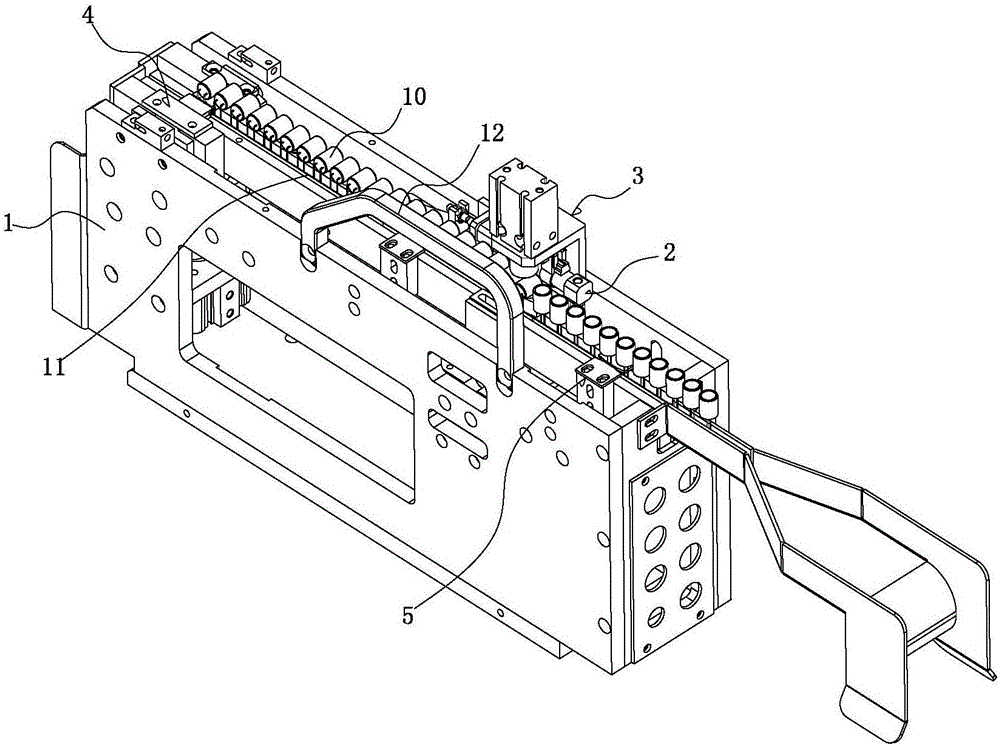

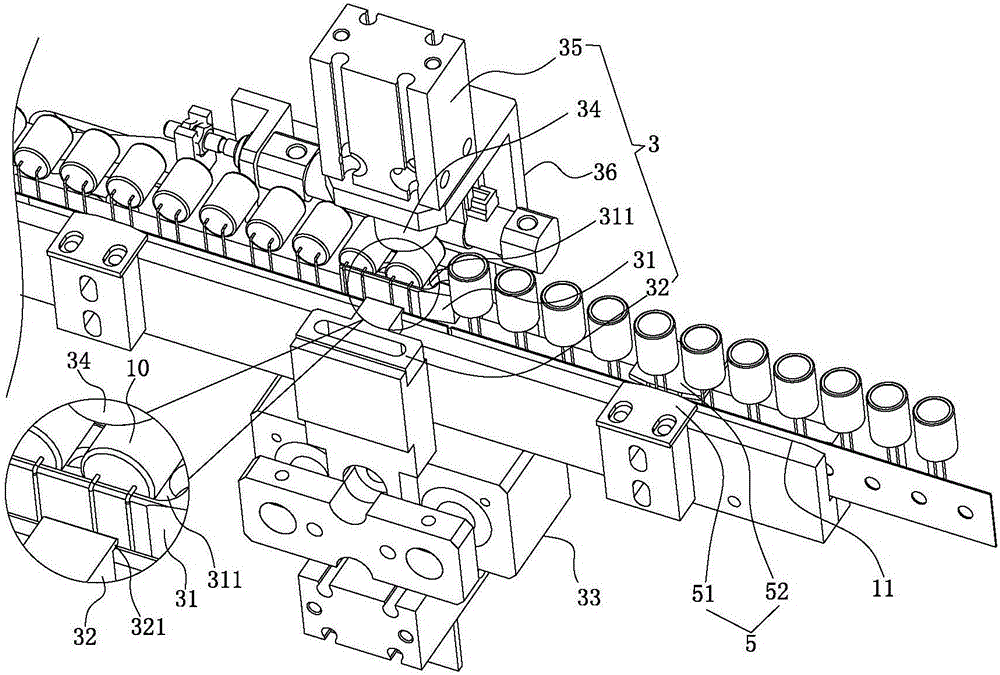

[0030] See Figure 1-5 As shown, it is a vertical feeding device for a sticking and inserting machine, which includes: a machine base 1 , a toggle feeding mechanism 2 installed on the machine base 1 , a bending mechanism 3 and a cutting mechanism 4 .

[0031] The machine base 1 is provided with a longitudinal trough 11 for electronic components 10 to pass through; the machine base 1 is provided with a foldable handle 12, and when in use, directly open the handle to directly lift The invention is very convenient to assemble, operate and use.

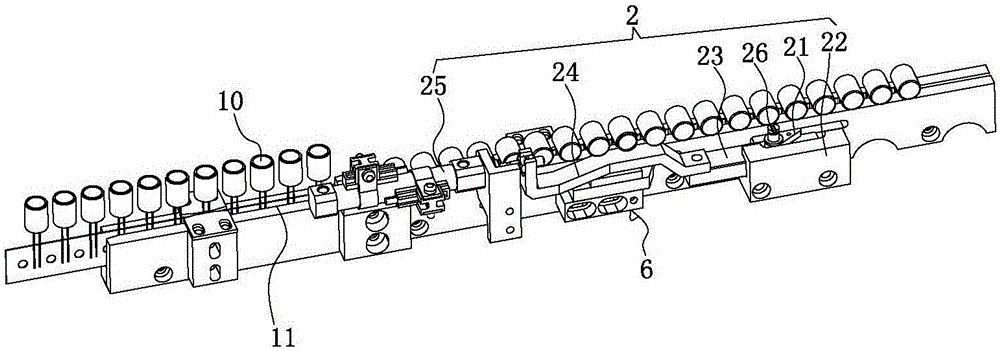

[0032] The toggle block 21 in the toggle feed mechanism 2 stretches into the trough 11; the toggle feed mechanism 2 includes a slide rail seat 22, a slide rail 23 that is worn on the slide rail seat 22, and a slide rail 23 connected drive link 24 and the first cylinder 25 for driving the drive link 24 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com