Rotor for a pyrolysis centrifuge reactor

A technology for reactors and reactor shells, applied in the rotor field of pyrolysis centrifugal reactors, which can solve the problem that large particles may be wedged between the blades 28 and the ablation surface 20a or wedged between the blades 28 and the ablation surface 20a and other problems, to achieve the effect of small residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In its most general aspect, the present invention relates to a PCR comprising a rotor that can be operated at relatively low rotational speeds while maintaining adequate productivity. By relatively low rotational speed is meant a rotational speed generally below 5000 rpm. Furthermore, the design of the PCR rotor of the present invention is capable of handling solid feeds with different particle sizes.

[0034] Thus, the rotor of the present invention is used to press solid feed, such as biomass, waste or fossil solid fuel, onto the surface of a heat pipe having a temperature between 300°C and 750°C, and also to convey solid feed and solid product through Tubular reactors to convert solid feed into carbon, tar and gas.

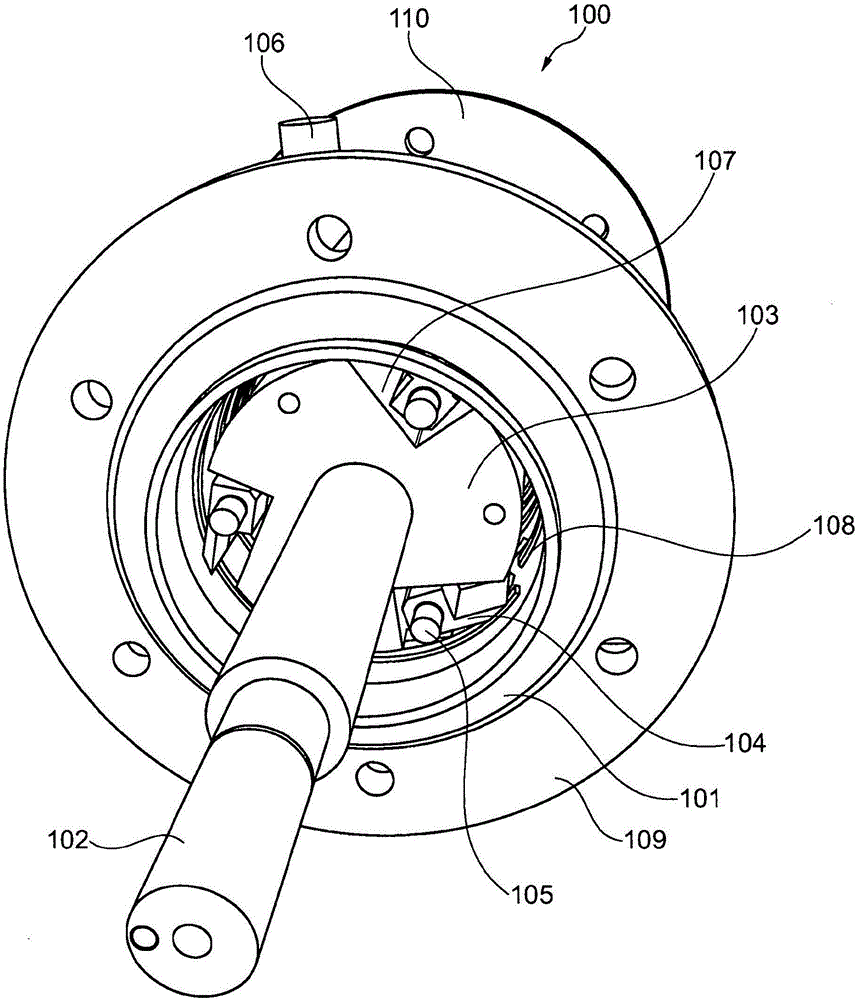

[0035] Refer below figure 1 , shows a PCR 100 having a reactor part 101 enclosing a rotor with a rotor body 103 arranged on a rotor shaft 102 . The solids feed to be processed enters the reactor part through the inlet 106 and leaves the reactor part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com