Elastic damping type railway metal sound barrier and combination device thereof

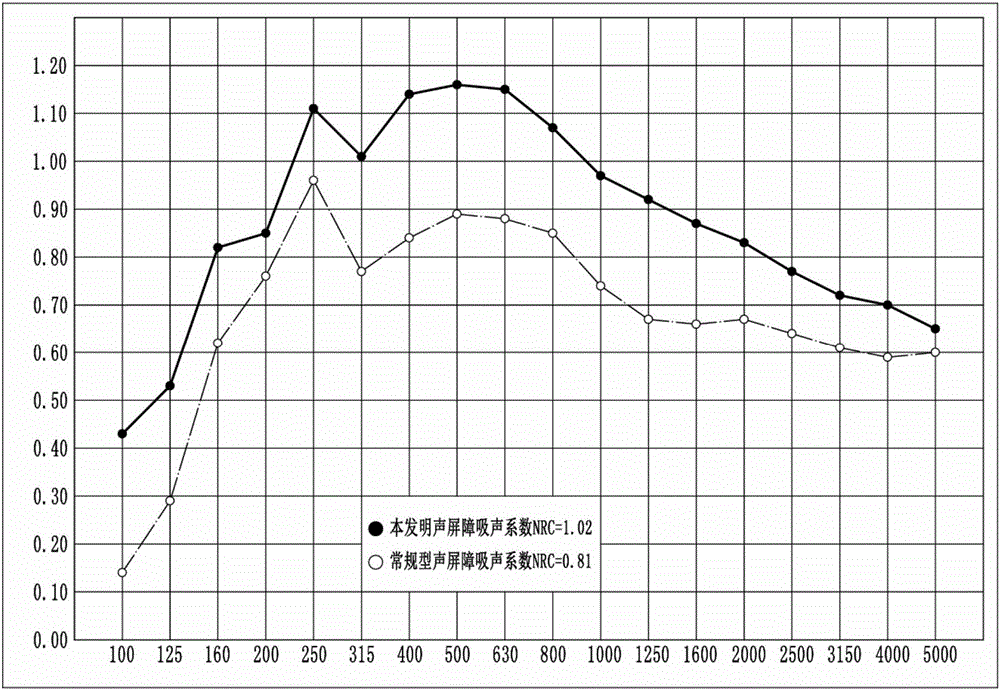

A technology of elastic damping and sound barrier, applied in the direction of noise absorption devices, buildings, etc., can solve problems such as safety hazards, shaking, driving safety threats, etc., to improve safety and life, increase effective sound absorption area, and improve anti-fatigue The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

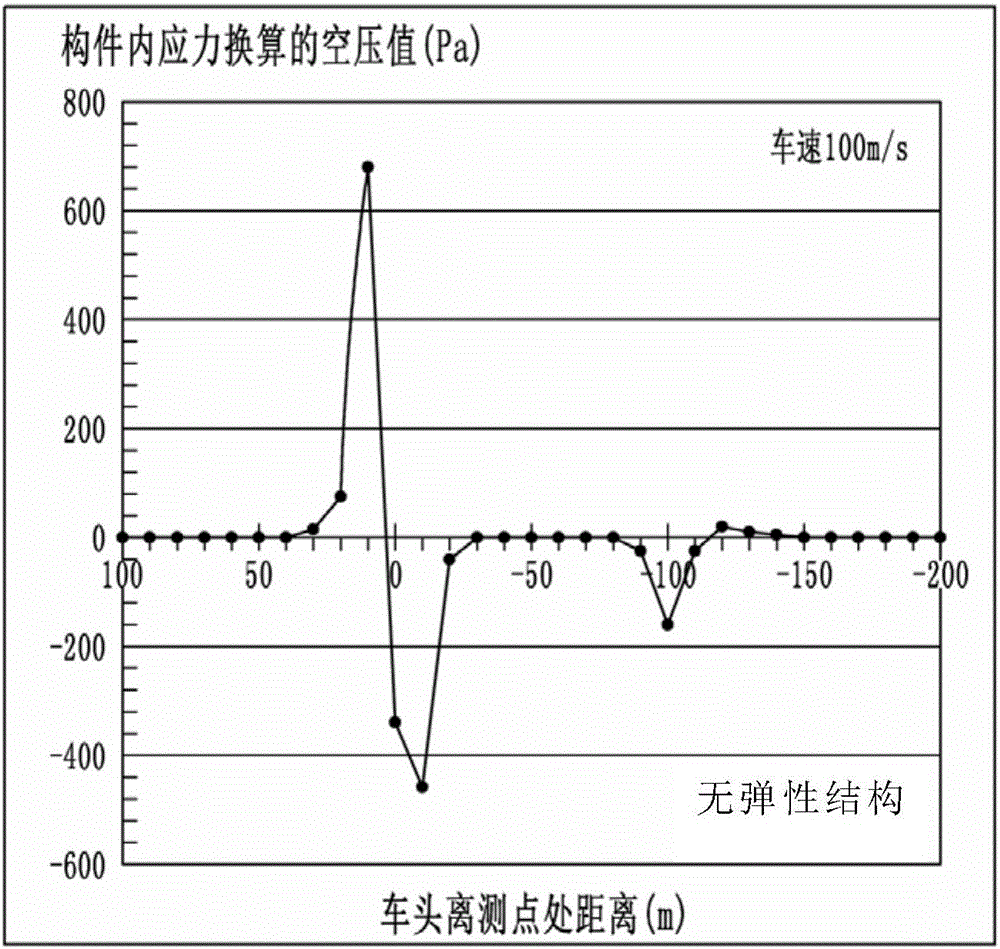

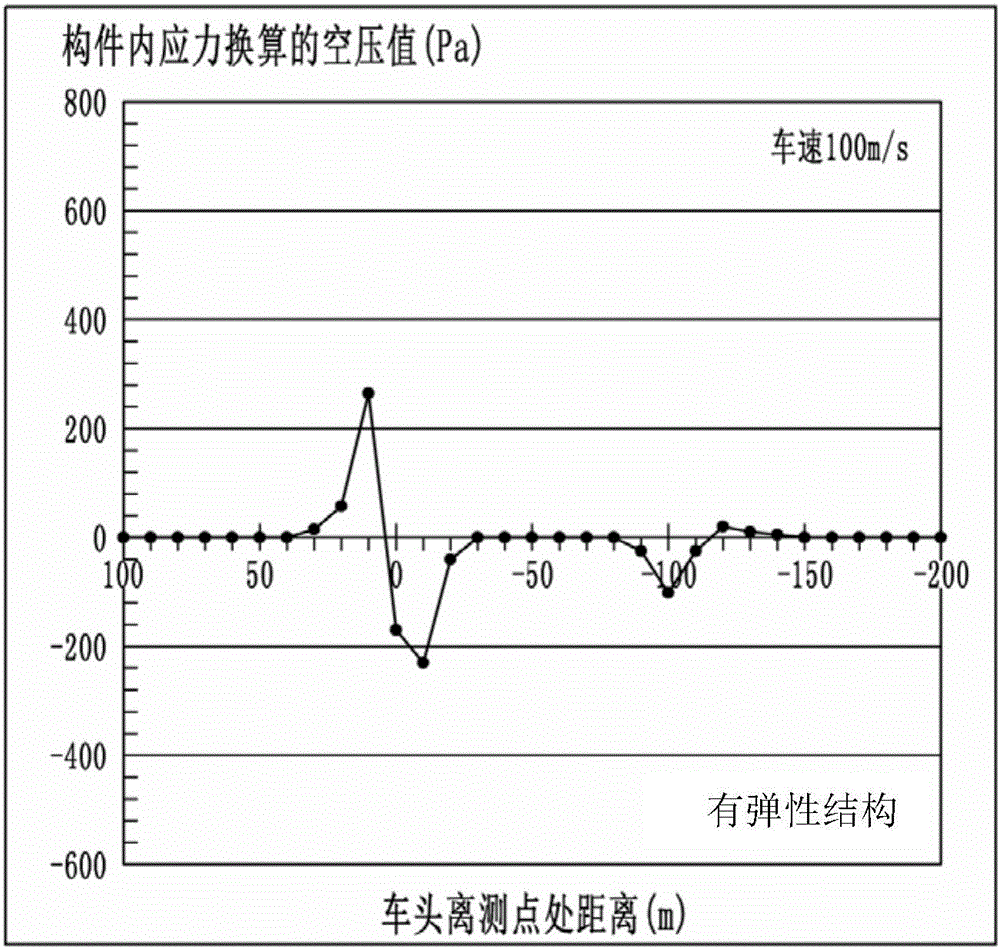

[0039] Such as image 3 and Figure 4 As shown, the elastic damping type railway metal sound barrier of the present invention, its unit plate mainly includes punching panel 3, elastic damping structure--rubber foam elastic strip 1, sound-absorbing material 6, reinforcing grid 5, back plate 7 and Aluminum alloy frame, etc., from the front to the back are punched panel 3, rubber foam elastic strip 1, reinforced grille 5, sound-absorbing material 6, reinforced grille 5, rubber foam elastic strip 1 and back plate 7, punched The perforated panel 3, the sound-absorbing material 6 and the back plate 7 are inserted into the slots of the aluminum alloy frame, and the aluminum alloy frame between the perforated panel 3 and the sound-absorbing material 6 and between the sound-absorbing material 6 and the back plate 7 A bearing slot for the rubber foam elastic strip 1 is arranged on the top, and the rubber foam elastic strip 1 is inserted into the bearing slot. The upper and lower edges...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com