Oil-immersed Transformer Fiber Optic Temperature Measuring Probe Fixing Device

An oil-immersed transformer and optical fiber temperature measurement technology, which is applied to measurement devices, thermometers and instruments with physical/chemical changes, etc., can solve the danger of safe operation of the power system, reduce the economic effect of the transformer, and the load capacity of the transformer cannot be fully utilized, etc. problem, to avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

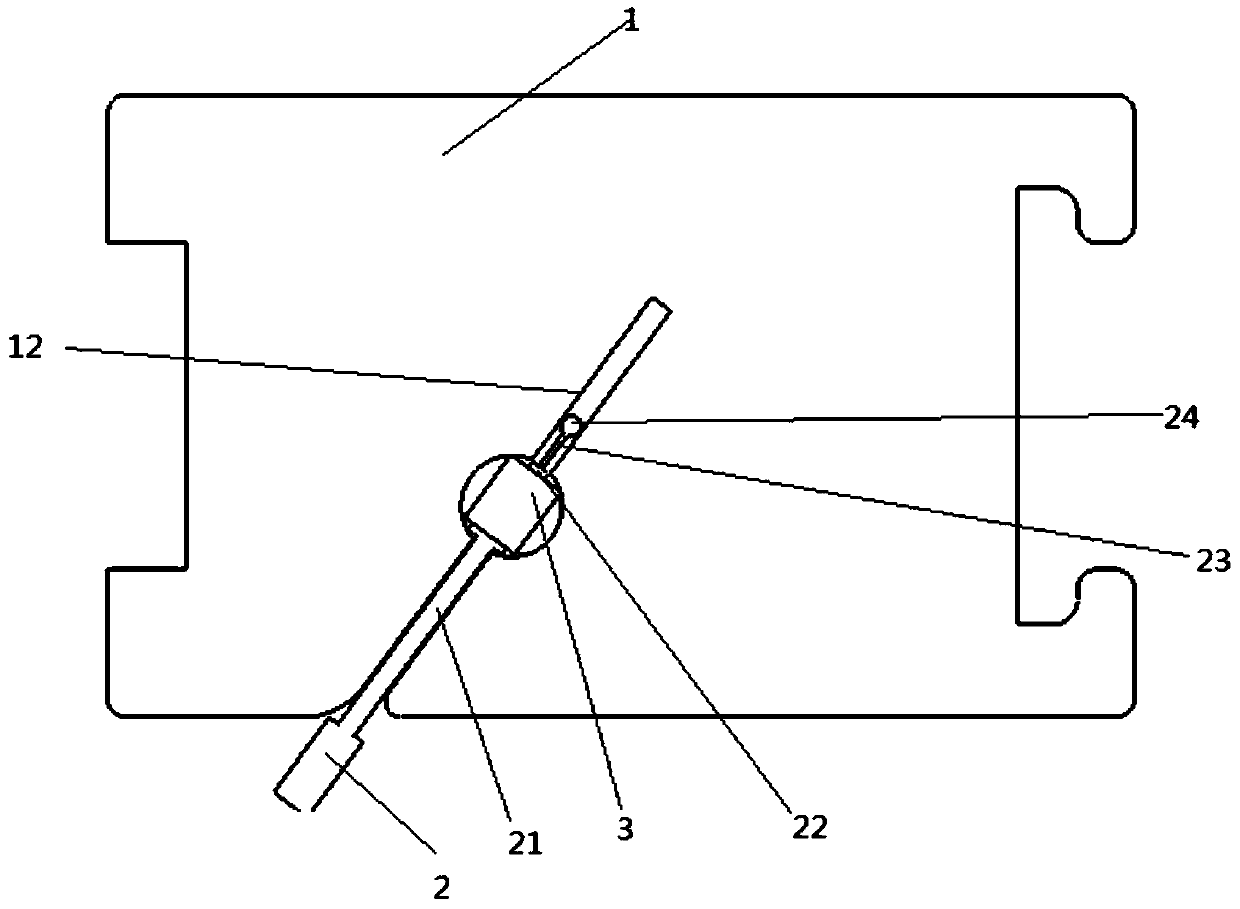

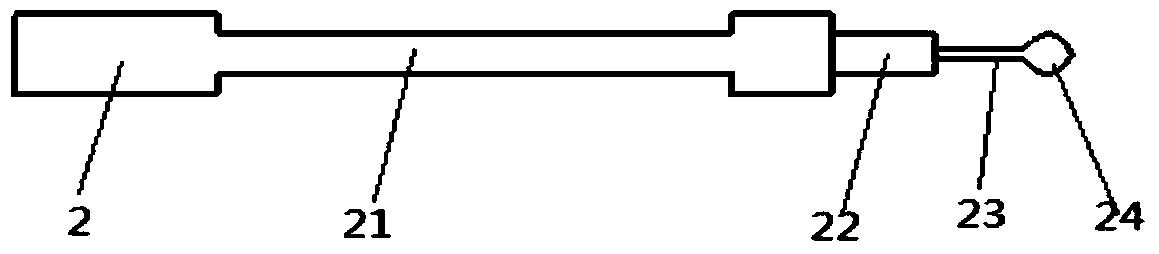

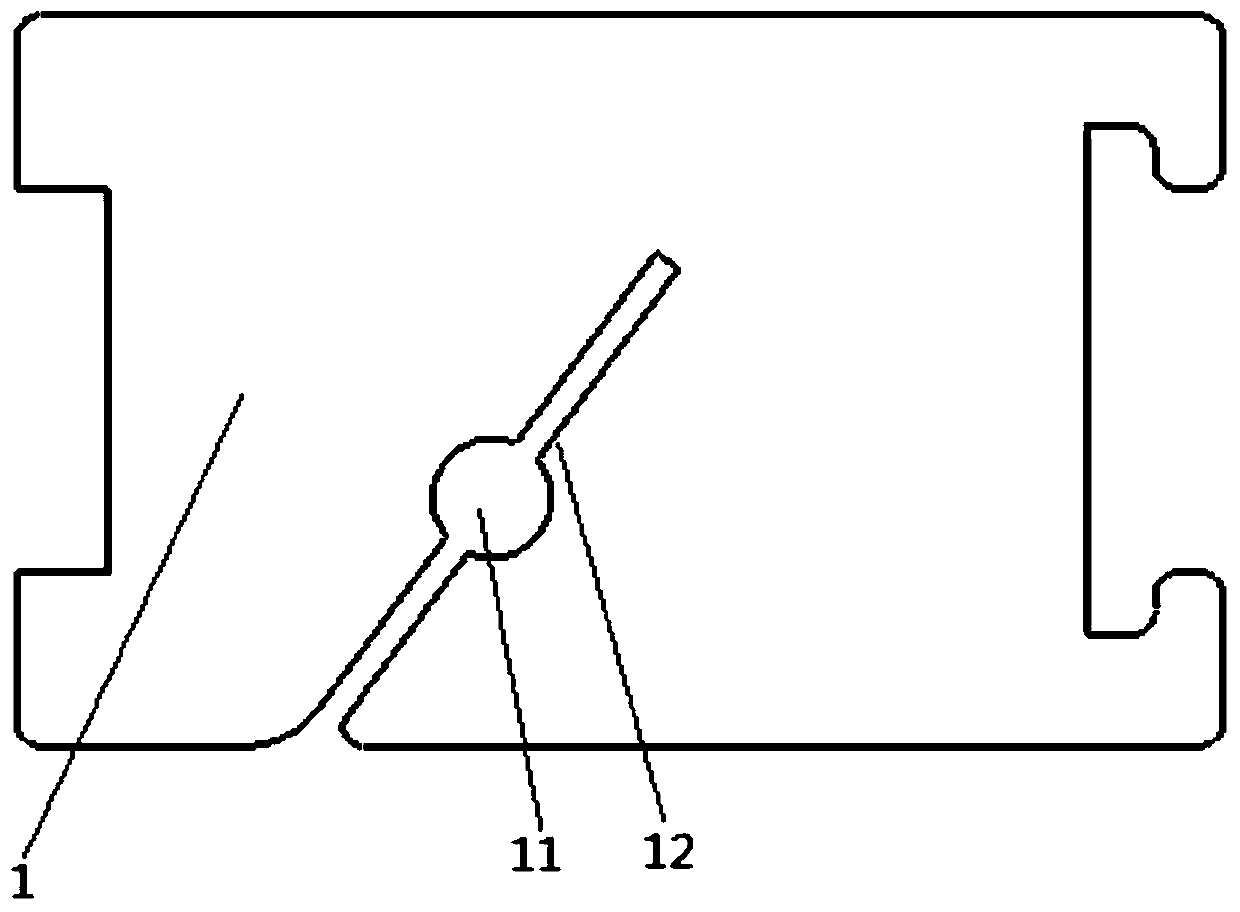

[0030] In this embodiment, the oil-immersed transformer fiber optic temperature measuring probe fixing device includes an insulating pad 1 arranged between the transformer coils, and the insulating pad 1 is provided with a strip that is adapted to the optical fiber temperature measuring probe assembly 2. A card slot hole 12, the strip-shaped card slot hole 12 is provided with a limit circular hole 11 larger than the diameter of the card slot hole 12; the optical fiber temperature measurement probe assembly 2 includes a transmission optical fiber and a An optical fiber temperature-sensing probe 24, the transmission optical fiber and the optical fiber temperature-sensing probe 24 are sequentially stuck in the strip-shaped card slot hole 12, wherein the transmission optical fiber passes through the limiting circular hole 11, and the transmission optical fiber The portion of the optical fiber corresponding to the limiting round hole 11 is provided with a limiting protrusion adapted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com