A method for creating synchronous image for strip tracking in continuous pickling line

A pickling line and strip steel technology, applied in rolling mill control devices, metal processing equipment, metal rolling, etc., can solve problems such as difficult programming, unfavorable fast recovery, troublesome modification, etc., and achieves easy implementation, strong versatility and Portability, the effect of restoring production line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

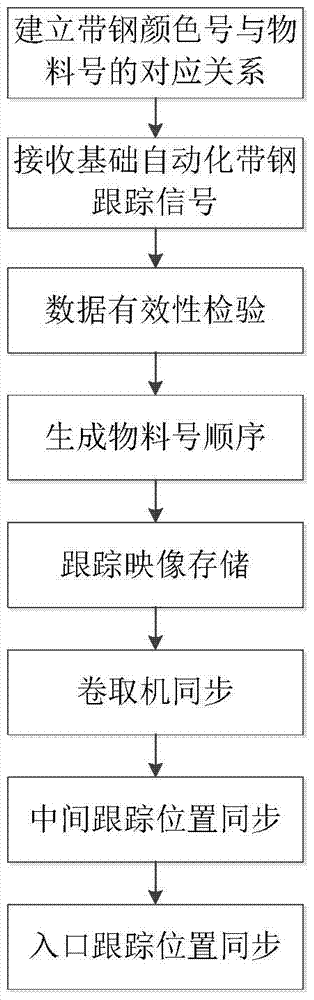

[0041] Such as figure 1 As shown, a method for creating a continuous pickling line strip tracking synchronous image provided by the present invention is as follows:

[0042] (1) Establish the corresponding relationship between strip steel color number and material number

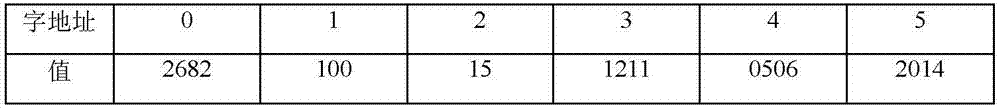

[0043] The setting value request message is defined according to the following format:

[0044] word address

size

describe

0

Int16

Message ID(2682)

1

Int16

lifetime count

2

Int16

Second

3

Int16

minute hour

4

Int16

day month

5

Int16

year

6

CHAR 20

Item number

16

Int16

Requested strip color number

17

Int16

Uncoiler No.

[0045] The requested strip color number is requested in the order of 1-10, and the maximum number of strips in the production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com