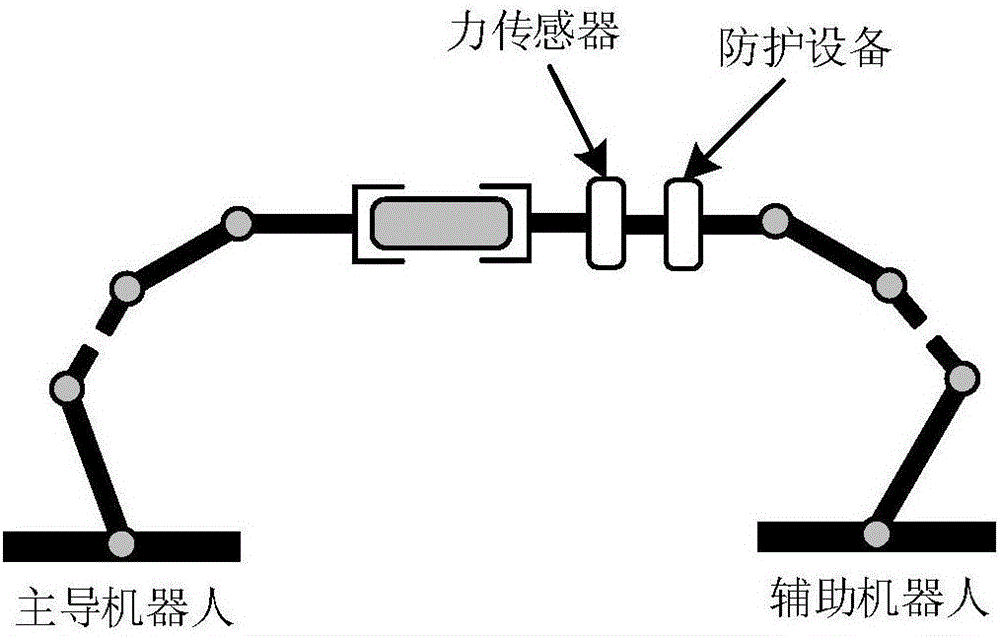

Double arm coordination acceleration control method based on impedance model under rigidity condition

A technology of acceleration control and impedance model, which is applied in the direction of program control of manipulators, manufacturing tools, manipulators, etc., can solve the problems of poor real-time performance of the arms, difficult control of internal forces, and difficult control of internal forces of both arms, so as to achieve smooth movement and solve difficult control of internal forces , the effect of real-time force tracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

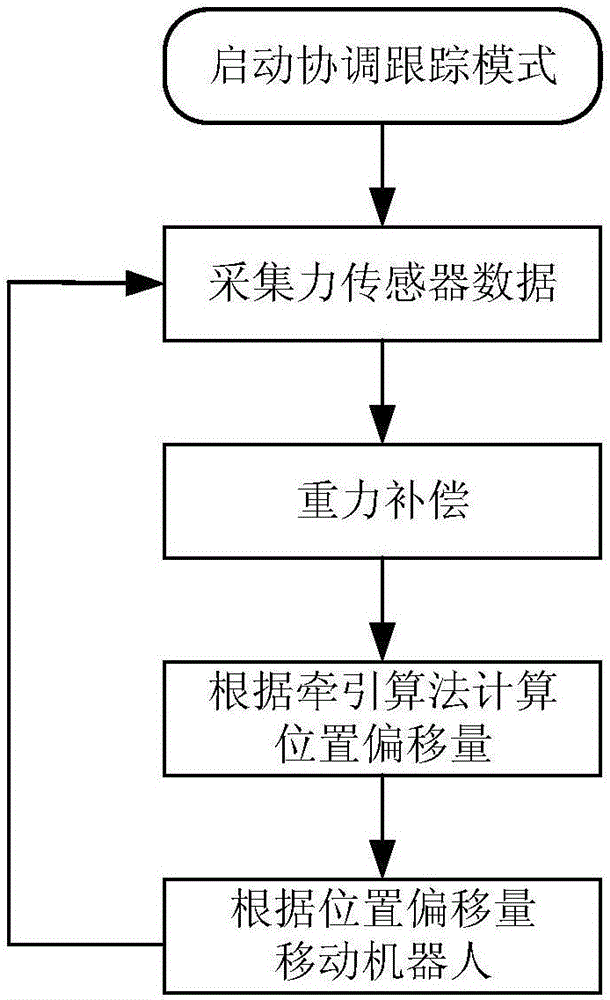

[0041] This specific embodiment discloses an acceleration control method based on an impedance model based on an impedance model under rigid conditions, including the following steps:

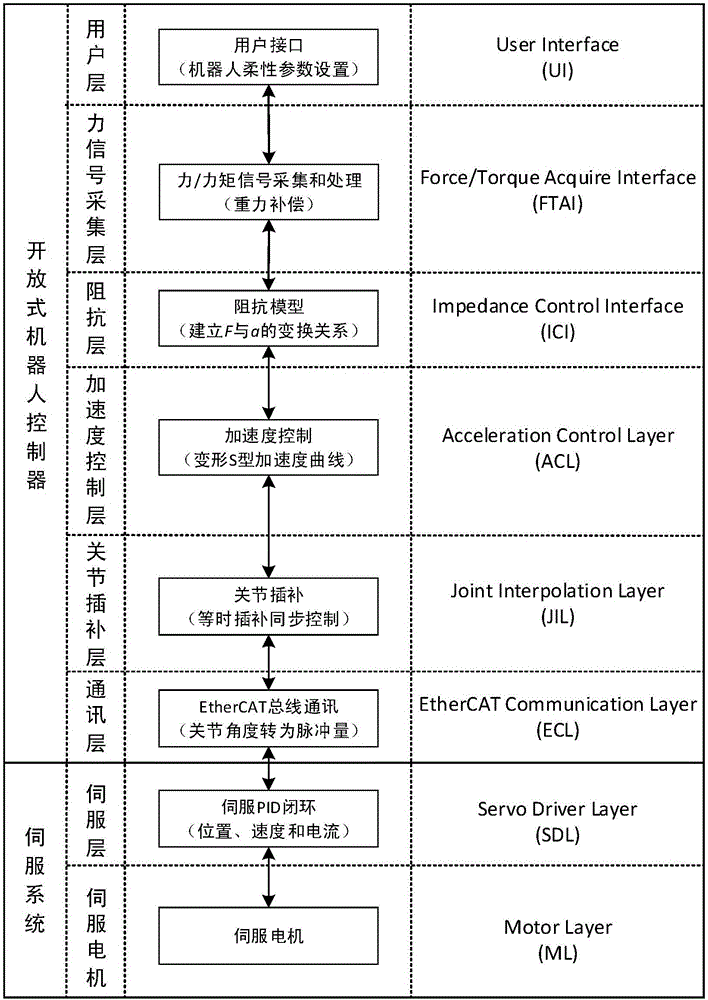

[0042] S1: The robot controller collects the information of the six-dimensional force sensor, first filters the collected information, then performs gravity compensation, and finally obtains the deviation data from the expected force or expected torque value;

[0043] S2: Transform the force deviation data or torque value deviation data into the acceleration of the end of the robot moving in the Cartesian space and the angular acceleration of the rotation around the axis according to the impedance model;

[0044] S3: Smoothly interpolate the motion according to the deformed S-shaped speed control curve, and obtain the corresponding position function, speed function, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com