Rotary copying cutter of plastic corrugated pipe cutting machine

A bellows and cutting machine technology, applied in metal processing and other directions, can solve the problems of left and right deviation, cutting into zigzags, bending deformation, etc., and achieve the effect of preventing excessive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and embodiments.

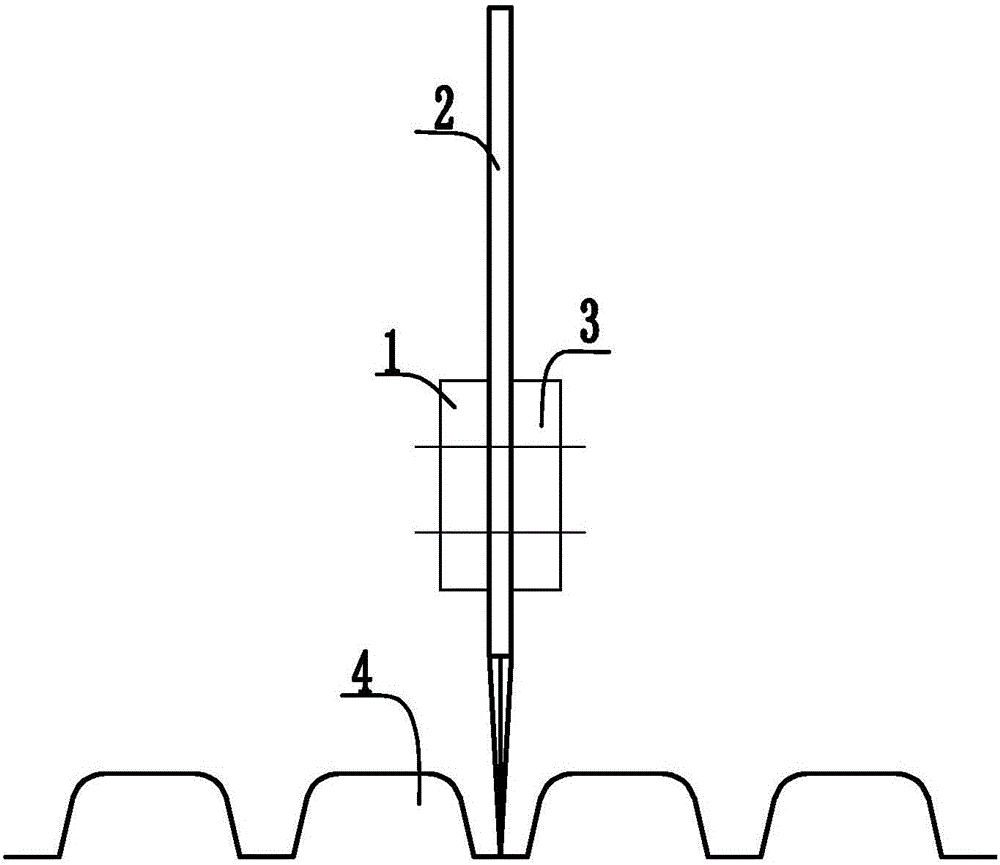

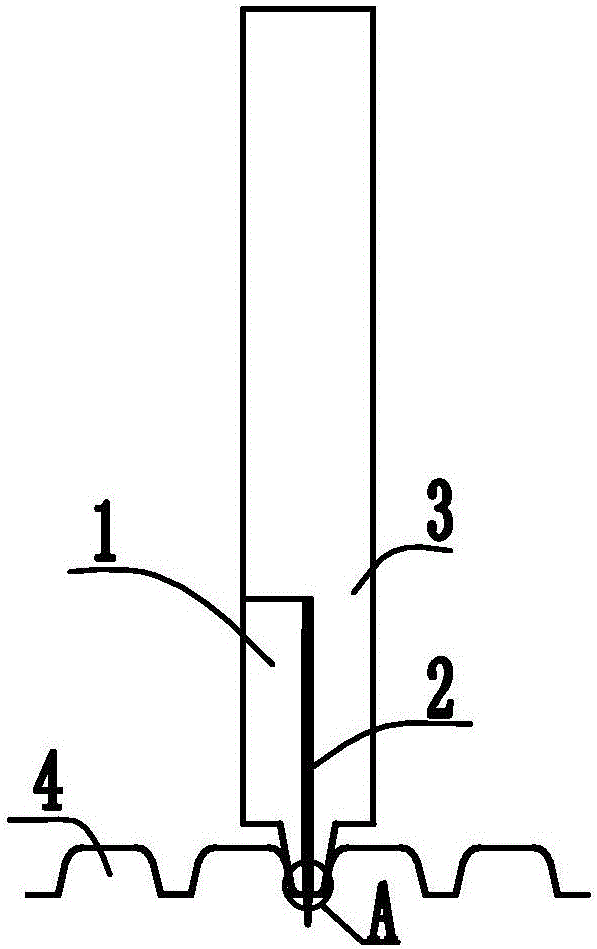

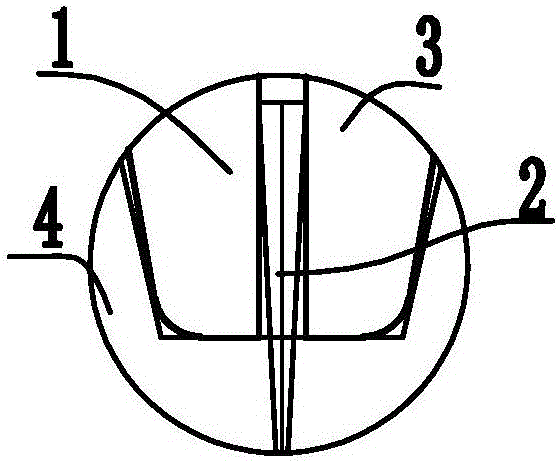

[0025] like Figure 2 to Figure 5 As shown, a rotary profile cutter of a plastic bellows cutting machine includes a cutting blade 2 and a fixed knife holder, and the cutting blade 2 includes a knife tip 21 and a knife handle end 22 . The cutting blade 2 is set inside the fixed blade holder, and the length of the cutting blade 2 extending from the fixed blade holder is between 1.1 and 5 times the thickness of the pipe material 4, so that the cutting blade 2 can only extend to the length that can cut through the corrugated pipe material 4; The shape of the bottom of the tool holder is a corrugated tooth shape, and the thickness of the bottom of the fixed tool holder is between 1.1 and 1.2 times the thickness of the corrugated bottom surface of the pipe 4, which can ensure that the bottom of the fixed tool holder cannot be in contact with the corrugated bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com