A vertical stop with a wear plate and a method for preventing steel springs from breaking

A vertical stopper and steel spring technology, applied in the direction of axle box installation, etc., can solve the problems of greatly improving the fracture resistance of steel springs, changing the stiffness without adjustment, and being difficult to effectively reduce the metal fatigue of steel springs, etc., to achieve a compact structure, Prevents breakage and has a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

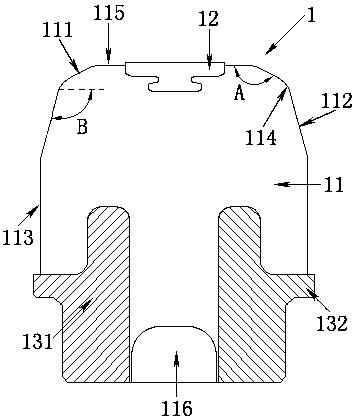

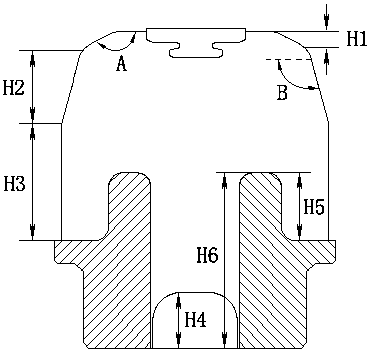

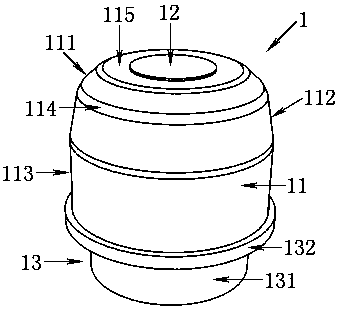

[0040] Such as Figure 5 As shown, a positioning base 4 is fixed above the axle box 5, and a double-volume spiral steel spring 2 is arranged above the positioning base 4, and the steel spring 2 supports the weight of the locomotive above the bogie frame 6. In order to reduce the vertical load borne by the steel spring 2 and reduce the metal fatigue generated by the steel spring 2 during locomotive operation, thereby preventing the steel spring 2 from breaking, a vertical stop 1 is provided in the steel spring 2 . The base flange 132 of the vertical stop 1 abuts against the positioning base 4 , and since the vertical stop 1 and the positioning base 4 are both revolving bodies, the vertical stop 1 can be stuck in the positioning base 4 . A frame guide cylinder 3 is arranged directly above the vertical stop 1. When the locomotive is unloaded, the vertical stop 1 does not contact the frame guide cylinder 3; when the vertical load of the locomotive increases, the frame guide cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com