A bottom-surface-integrated anti-fouling and anti-corrosion nano polysiloxane coating and its preparation method

A polysiloxane and polysiloxane resin technology, which is applied in the field of nanoparticle modification technology and coatings, can solve rare problems such as reducing the number of spraying passes, increase density, and improve corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

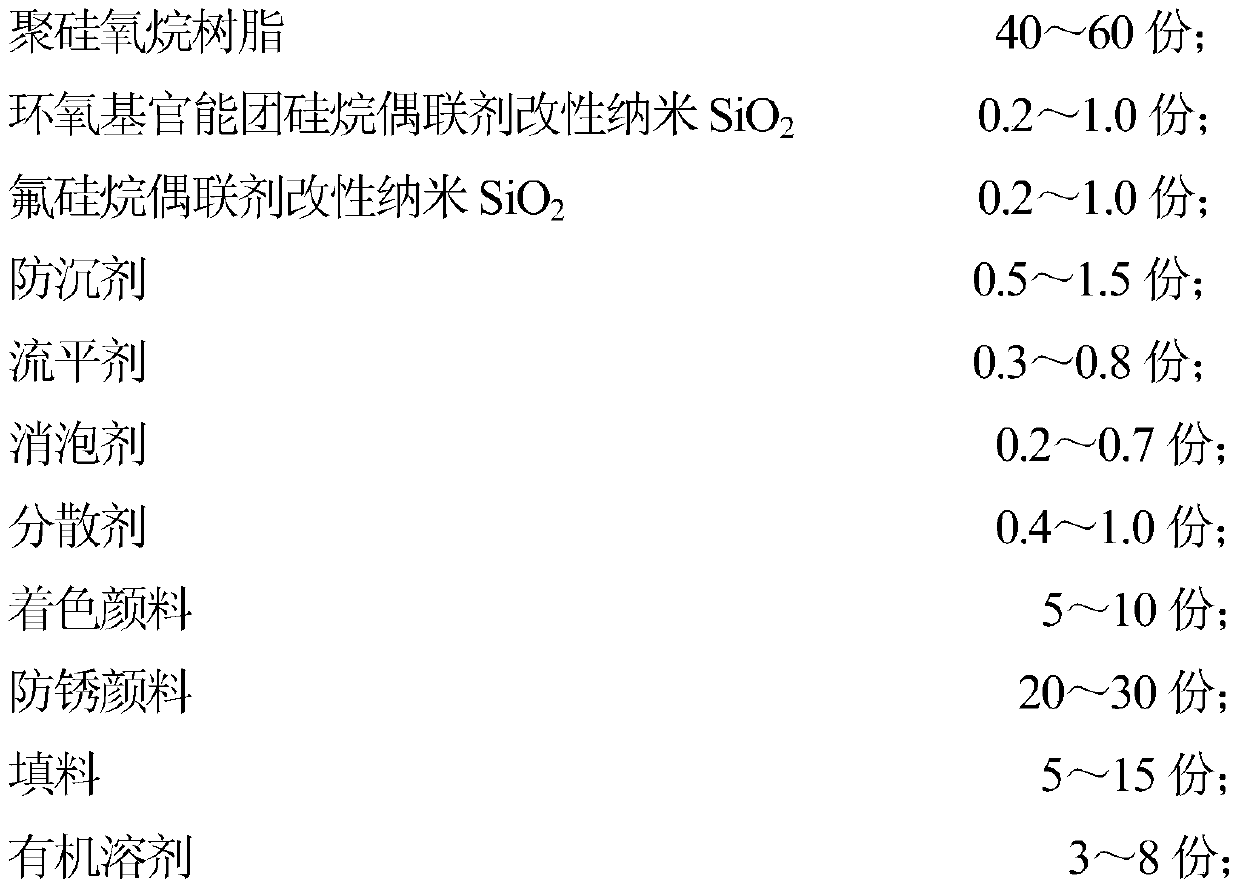

Method used

Image

Examples

Embodiment 1

[0044] 1. Nano-SiO modified by epoxy functional group silane coupling agent 2 Modified nano-SiO with fluorosilane coupling agent 2 preparation of

[0045] 1) Epoxy functional group silane coupling agent modified nano-SiO 2

[0046] nano-SiO 2 Added to 3-glycidyloxypropyltriethoxysilane to make nano-SiO 2 The mass fraction is 20%; then add nano-SiO 2 Prepare a mixture of 40 times the mass of water and 40 times the mass of isopropanol. The mixture was heated and stirred at 80° C. under slightly acidic (pH=5) conditions for 1 h. Finally, the mixture was dried at 30°C. After grinding, pass through a 325 mesh sieve to obtain epoxy functional group silane coupling agent modified nano-SiO 2 pink.

[0047] 2) Nano-SiO modified by fluorosilane coupling agent 2

[0048] nano-SiO 2 Added to heptadecafluorodecyltrimethoxysilane to make nano-SiO 2 The mass fraction is 20%; then add nano-SiO 2 Prepare a mixture of 40 times the mass of water and 3 times the mass of ethanol. Th...

Embodiment 2

[0054] 1. Nano-SiO modified by epoxy functional group silane coupling agent 2 Modified nano-SiO with fluorosilane coupling agent 2 preparation of

[0055] 1) Epoxy functional group silane coupling agent modified nano-SiO 2

[0056] nano-SiO 2 Added to 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane to make nano-SiO 2 The mass fraction is 25%; then add nano-SiO 2 Prepare a mixture of 45 times the mass of water and 50 times the mass of isopropanol. The mixture was heated and stirred at 100° C. and slightly acidic (pH=5.5) for 0.5 h. Finally, the mixture was dried at 40°C. After grinding, pass through a 325 mesh sieve to obtain epoxy functional group silane coupling agent modified nano-SiO 2 pink.

[0057] 2) Nano-SiO modified by fluorosilane coupling agent 2

[0058] nano-SiO 2 Added to dodecafluoroheptylpropylmethyldimethoxysilane to make nano-SiO 2 The mass fraction is 25%; then add nano-SiO 2 Prepare a mixture of 45 times the mass of water and 5 times the mass o...

Embodiment 3

[0064] 1. Nano-SiO modified by epoxy functional group silane coupling agent 2 Modified nano-SiO with fluorosilane coupling agent 2 preparation of

[0065] 1) Epoxy functional group silane coupling agent modified nano-SiO 2

[0066] nano-SiO 2 Added to γ-(2,3-glycidoxy)propyltrimethoxysilane to make nano-SiO 2 The mass fraction is 30%; then add nano-SiO 2 Prepare a mixture of 50 times the mass of water and 45 times the mass of isopropanol. The mixture was heated and stirred at 90° C. for 2 h under slightly acidic (pH=4.5) conditions. Finally, the mixture was dried at 50°C. After grinding, pass through a 325 mesh sieve to obtain epoxy functional group silane coupling agent modified nano-SiO 2 pink.

[0067] 2) Nano-SiO modified by fluorosilane coupling agent 2

[0068] nano-SiO 2 Added to trifluoropropyltrimethoxysilane to make nano-SiO 2 The mass fraction is 30%; then add nano-SiO 2 Prepare a mixture of 50 times the mass of water and 4 times the mass of ethanol. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com