Wool yarn loosening mechanism for towel loom

A towel machine, loose wool technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of reducing weaving efficiency, affecting normal weaving, time-consuming and laborious, and achieving the effect of improving weaving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

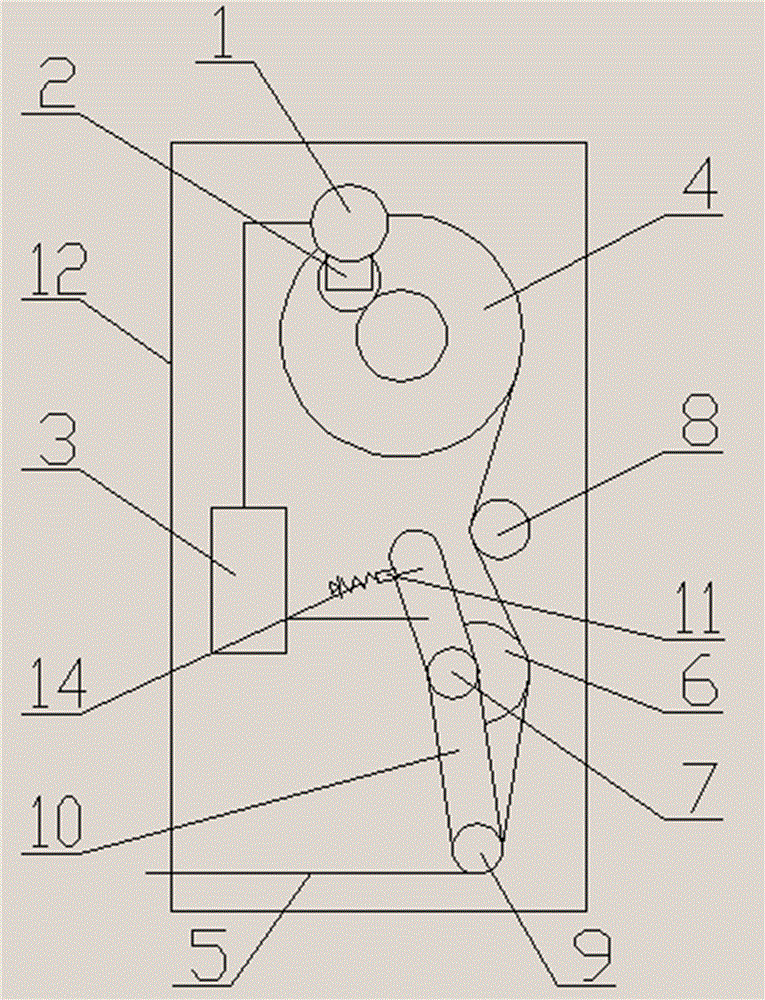

[0016] figure 1 As shown, a loosening mechanism of a towel machine includes a hair feeding servo motor 1, a reducer 2, an electric box 3, a wool yarn shaft 4, a wool yarn 5, a thin-walled elastic tube 6, a support shaft 7, a guide roller 8, and a tension control roller 9 , Tension lever 10, tension sensor 11 and spring 14. The wool feeding servo motor 1 is set on the towel machine frame 12 through the reducer 2, the reducer 2 drives the wool yarn shaft 4 on the towel machine frame through the transmission of large and small reduction gears, and the guide roller 8 is connected to the towel machine frame 12 A buffer elastic tube assembly is arranged parallel to the yarn shaft 4 and the guide roller 8, the buffer elastic tube assembly includes a thin-walled elastic tube 6 and a support shaft 7, and the thin-wall elastic tube 6 is wrapped around the support shaft by a thin-walled spring plate at both ends The pressing piece is fixedly connected to the support shaft, and there is ...

Embodiment 2

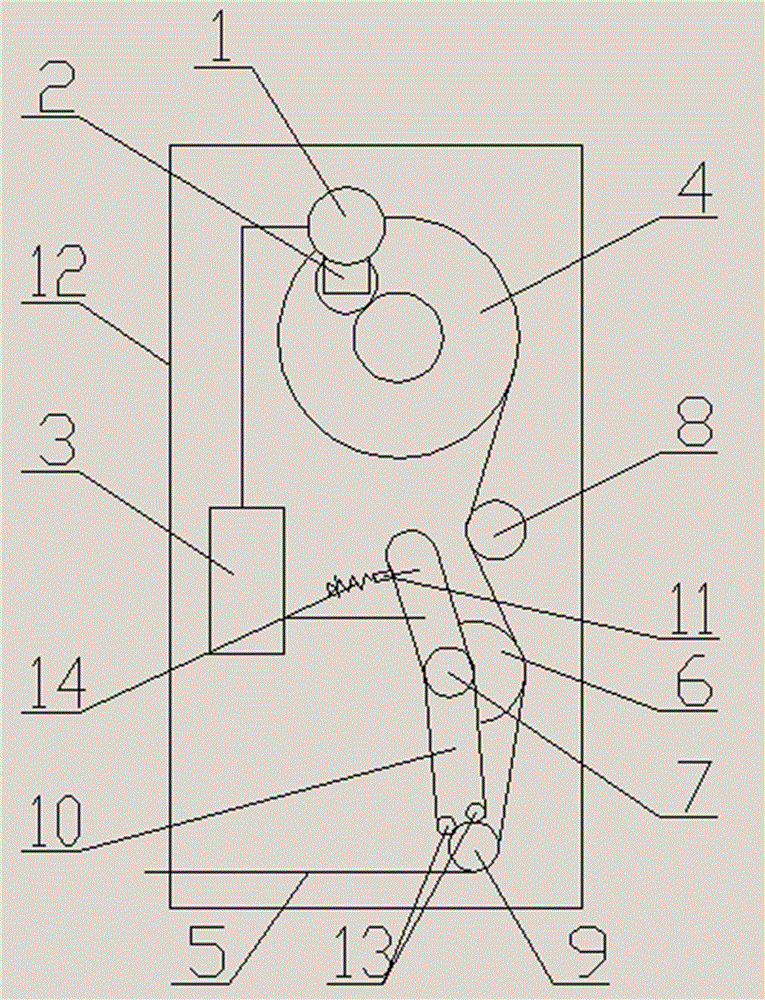

[0018] figure 1 As shown, a towel loosening mechanism, wherein the lower end of the tension lever 10 is provided with two support rollers 13, and the two support rollers 13 press against and drive the tension control roller 9, and the two ends of the tension control roller 9 are connected to the tension lever. It can be supported by the support roller 13 to rotate. All the other structures are the same as in Example 1.

[0019] On the basis of the above-mentioned embodiments, the middle part or the other end of the tension lever 10 can also be fixedly connected to the support shaft of the buffer elastic tube assembly by screws to rotate around the center of the support shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com