Assembled pre-fabricated AB-surface multifunctional wall body

A multi-functional, prefabricated technology, applied in manufacturing tools, building components, building materials, etc., can solve the problems of warping and deformation of the outer wall, affecting the accuracy, safety hazards of the connecting rod of the sandwich wall insulation layer, etc., to reduce the load. , Overcome the effect of warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings. It is obvious that the described embodiments are only some of the embodiments of the invention.

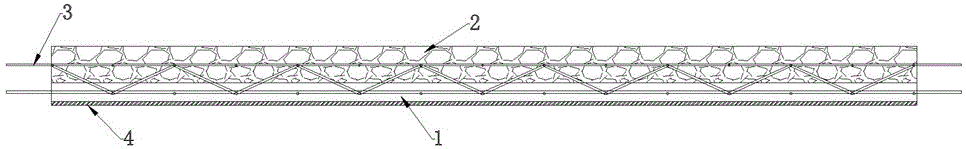

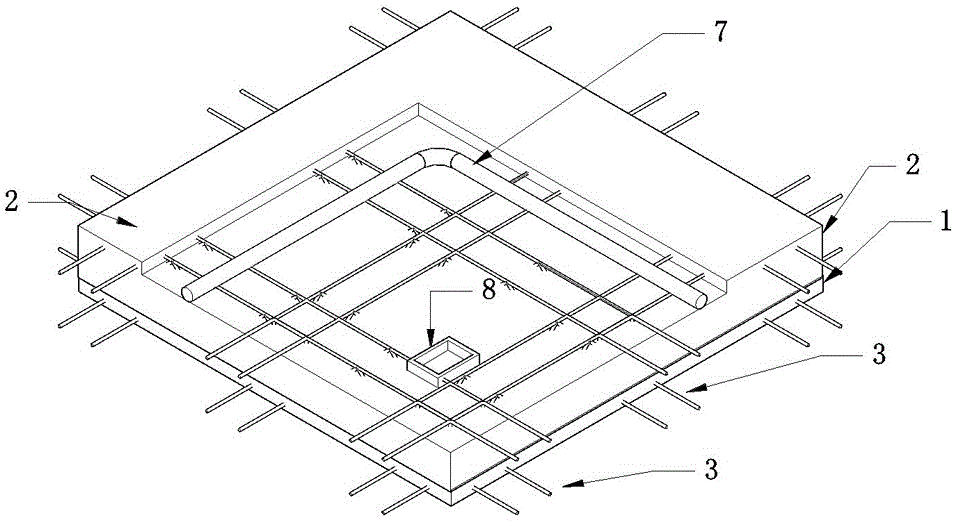

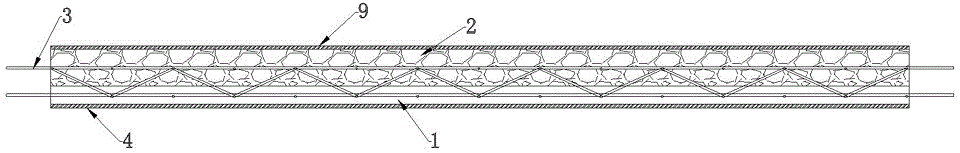

[0045] like figure 1 In the embodiment shown, a prefabricated prefabricated AB face multifunctional wall, wherein the outer wall A face 1 is made of ordinary concrete, the inner wall B face 2 is made of aerated concrete, the outer wall A face 1 and the inner wall The interior of the body B-side 2 is provided with a steel mesh 3 and a steel truss, and the steel mesh 3 is connected by a steel truss.

[0046]The construction method is as follows:

[0047] a. Support the formwork at the construction site, set up the bottom formwork according to the design requirements of the length and width of the wall, and set up the side formwork according to the thickness of the wall; the side formwork has reserved holes for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com