Process method for reducing deformation of micro suspension structure in chemically mechanical thinning and polishing process

A thinning polishing, chemical mechanical technology, applied in the direction of polishing machine tools, manufacturing tools, metal processing equipment, etc., can solve the problems of stress reduction, warping deformation, etc., to achieve the goal of reducing warping deformation, improving performance and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

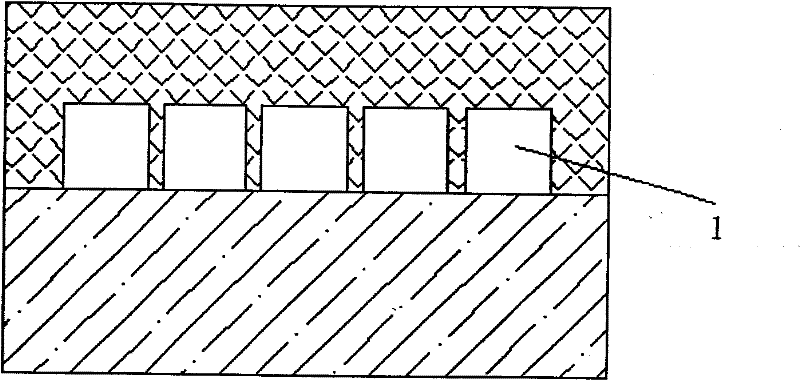

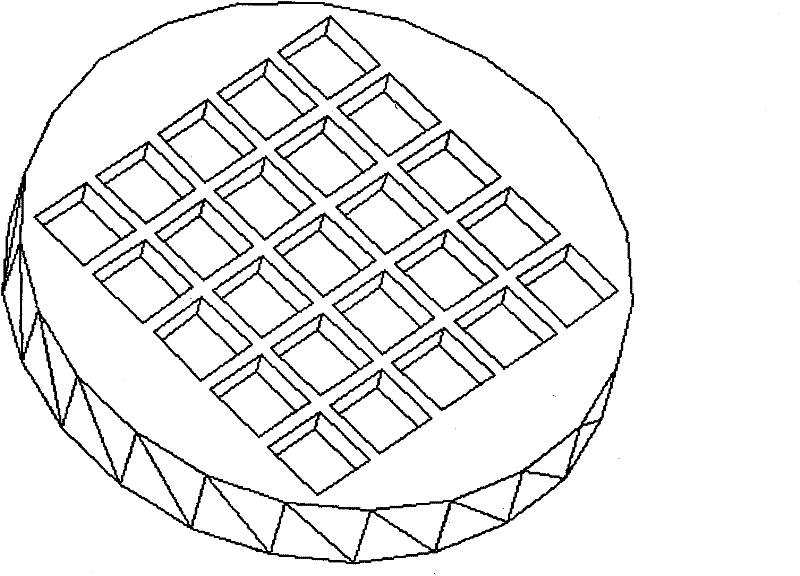

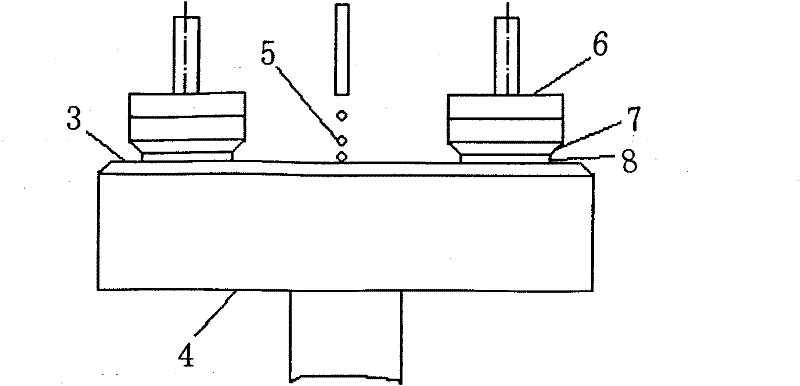

[0018] 1. The process sheet in this process is a two-layer bonded wafer, such as figure 1 As shown, the front side of the wafer that needs to be thinned and polished is the thinned side, and the back side is the bonding side. According to design requirements, wet etching or dry etching is used on the back to form a cavity structure array, such as figure 2 shown. image 3 A schematic diagram of chemical mechanical thinning and polishing is shown. In the chemical mechanical thinning and polishing process of the cavity structure, due to the pressure of the grinding block, the cavity structure will be warped and deformed, such as Figure 4 shown. After thinning and polishing, the cavity structure is released by wet etching or dry etching to form a movable suspension structure that is only connected to the anchor area through thin beams. Due to the stress introduced by thinning and polishing, it cannot be effectively released in the suspension structure. There will be a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com