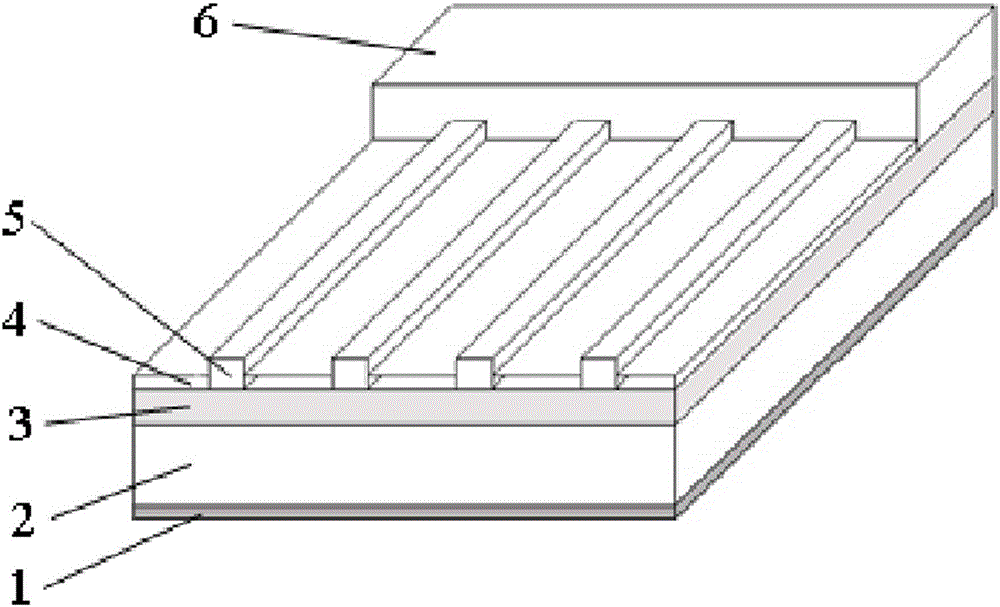

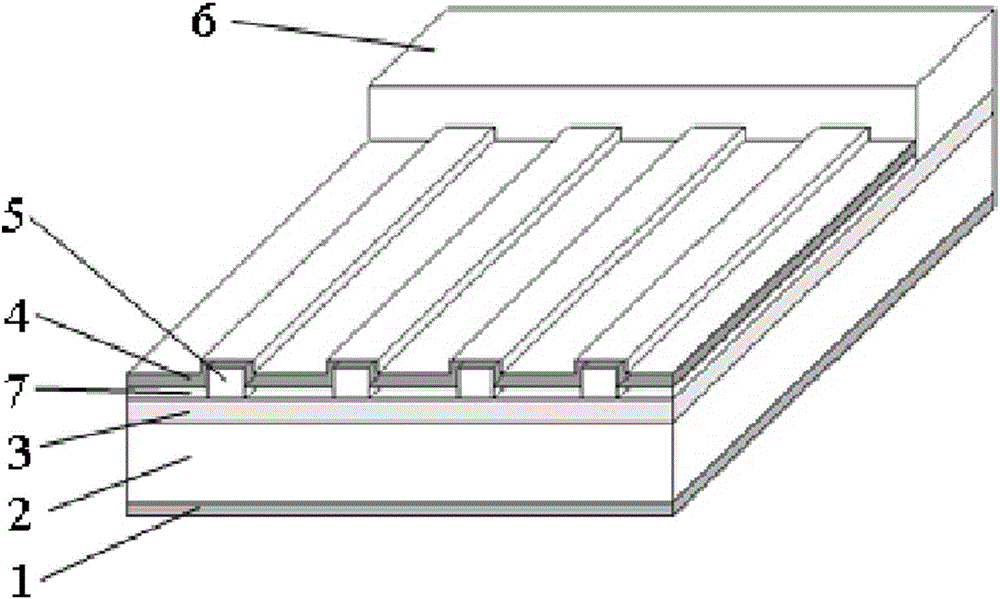

A new method for grooving front grid line electrode of crystalline silicon solar cell and manufacturing method of the solar cell

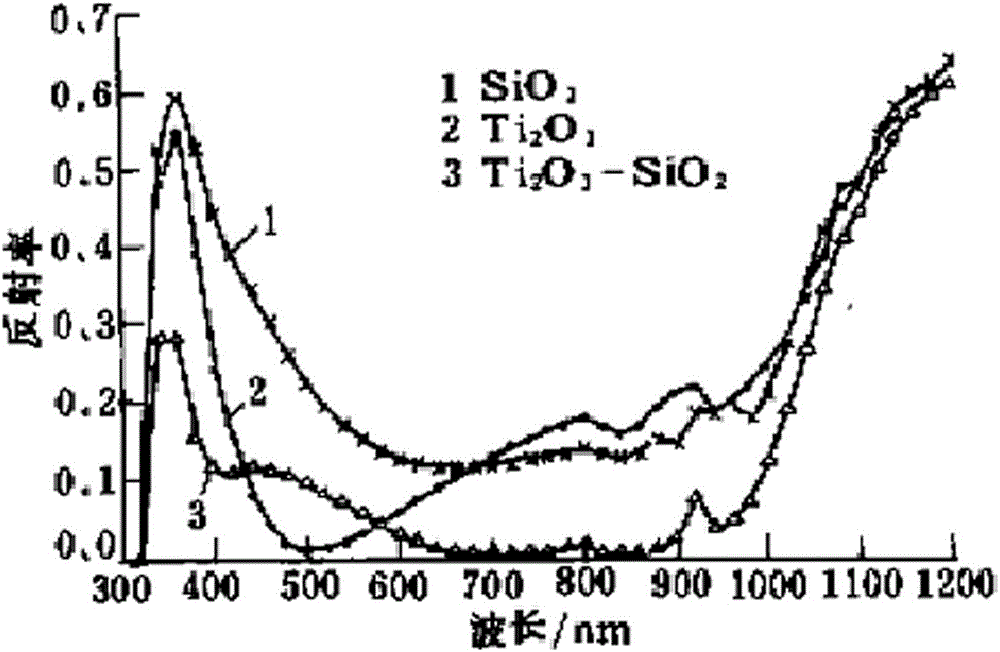

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as poor contact, large shadow loss, and high cost, so as to reduce shadow loss, reduce production costs, and reduce The effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Embodiment 1: preparing an electrolytic solution for light induction, the electrolytic solution is a plating solution containing 0.01 mol / L of Co metal ions, which is filled in an electrolytic cell. Place the N region of the solar cell after cleaning the texture, diffusing to make the P-N junction, etching and dephosphorizing, and making the back electrode in the electrolyte, and connect the back electrode surface and the counter electrode placed in the electrolyte with wires, to form a closed loop. Slots are made in the N area of the solar cell, and the light emitted by the fluorescent lamp is irradiated on the N area of the solar cell to form a grid line shape. Metal ions are reduced to metal deposits in the illuminated area. At the same time, the photogenerated holes are transported along the wire to the counter electrode to dissolve the metal into metal ions to supplement the loss of ions in the solution, so the reaction continues until the electric quantity me...

Embodiment 2

[0109]Example 2: An electrolytic solution for light induction was prepared, the electrolytic solution was a plating solution containing 1 mol / L Ni metal ions, and it was filled in an electrolytic cell. Place the N region of the solar cell after cleaning the texture, diffusing to make the P-N junction, etching and dephosphorizing, and making the back electrode in the electrolyte, and connect the back electrode surface and the counter electrode placed in the electrolyte with wires, to form a closed loop. Slots are made in the N area of the solar cell, and the light emitted by the fluorescent lamp is irradiated on the N area of the solar cell to form a grid line shape. Metal ions are reduced to metal deposits in the illuminated area. At the same time, the photogenerated holes are transported along the wire to the counter electrode to dissolve the metal into metal ions to supplement the loss of ions in the solution, so the reaction continues until the electric quantity measur...

Embodiment 3

[0110] Embodiment 3: preparing an electrolytic solution for light induction, the electrolytic solution is a plating solution containing 0.3 mol / L of Co metal ions, which is filled in an electrolytic cell. Place the N region of the solar cell after cleaning the texture, diffusing to make the P-N junction, etching and dephosphorizing, and making the back electrode in the electrolyte, and connect the back electrode surface and the counter electrode placed in the electrolyte with wires, to form a closed loop. Slots are made in the N area of the solar cell, and the light emitted by the fluorescent lamp is irradiated on the N area of the solar cell to form a grid line shape. Metal ions are reduced to metal deposits in the illuminated area. At the same time, the photogenerated holes are transported along the wire to the counter electrode to dissolve the metal into metal ions to supplement the loss of ions in the solution, so the reaction continues until the electric quantity mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com