Floating structure of high-temperature hot end connector of aero-engine

A technology of aero-engine and floating structure, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of thermal expansion and deformation of aero-engine hot-end connectors, and achieve improved test pass rate, reliable operation, and safe and reliable use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

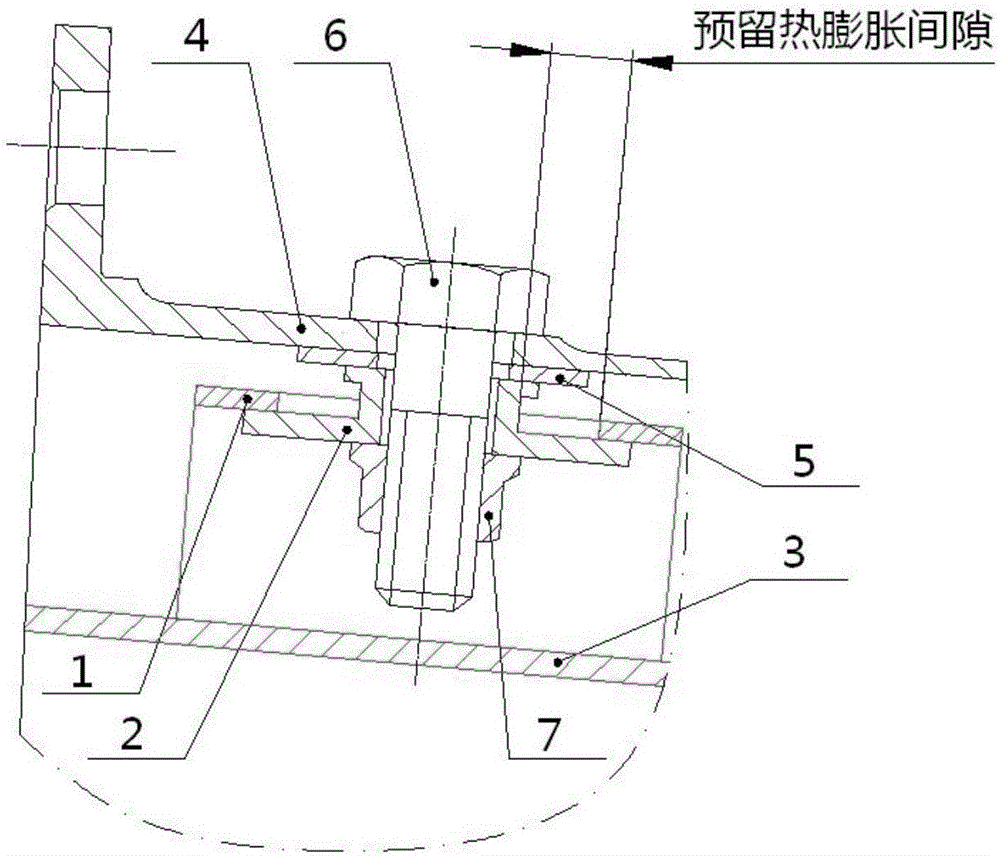

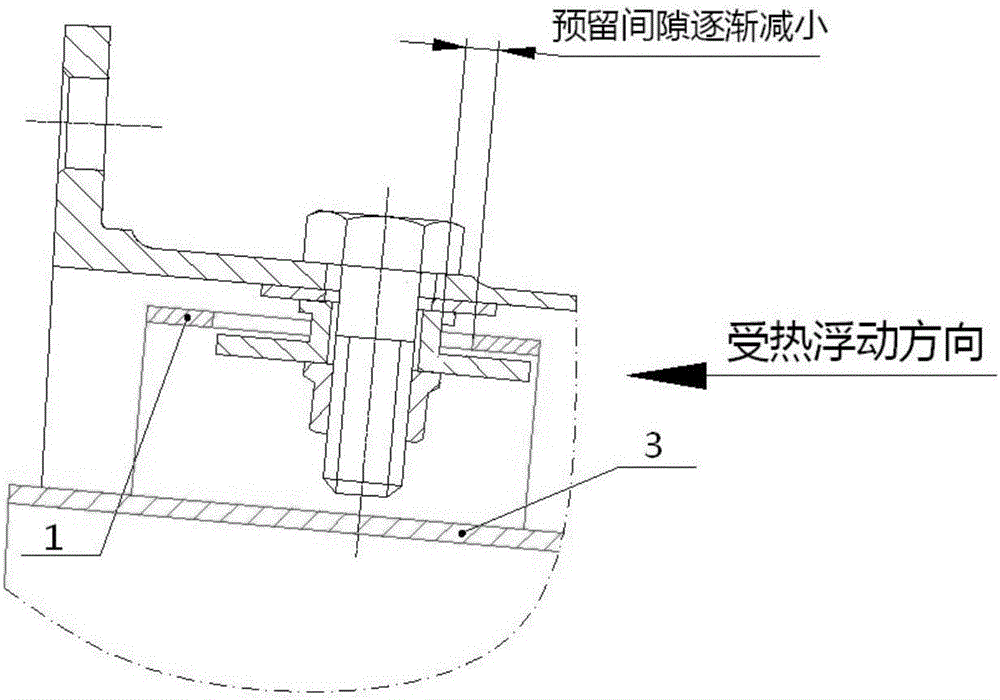

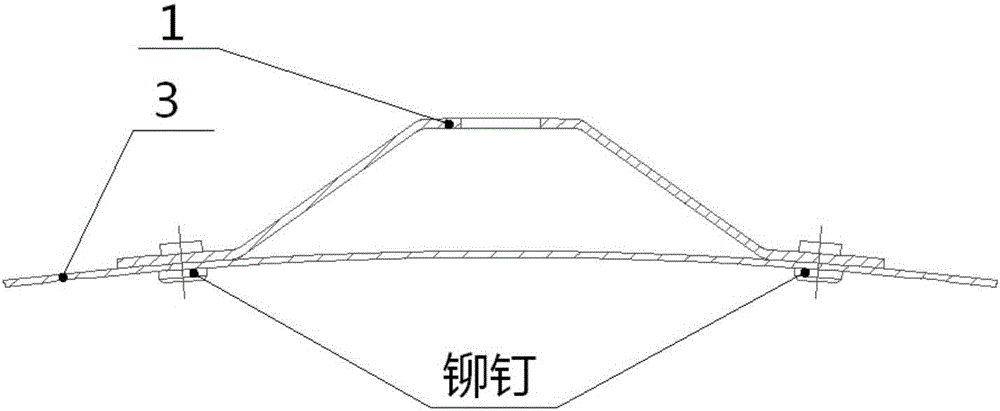

[0025] The connector structure has a floating function in the high temperature working state. The core components of the floating function are the floating bracket 1 and the spacer bushing 2; a certain amount of thermal expansion gap is reserved for the initial assembly of the floating bracket 1 and the spacer bushing 2 in the stationary state of the engine. The internal thin-walled part 3 is in a high-temperature environment and expands due to thermal deformation. The thin-walled part 3 and the floating bracket 1 float along the axial direction of the reserved gap. As the ambient temperature rises, the floating amount continues to increase until the ambient temperature increases. The temperature reaches the maximum and no longer changes, the thin-walled part 3 and the floating support 1 float to the maximum position, and after the engine stops working, the connecting part returns to the starting position again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com