Hub bearing sealing ring of railway wagon and bearing equipped with same

A technology for wheel hub bearings and railway wagons, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as degumming, low friction torque, and poor reliability, and achieve the effects of reducing heat generation, strong torsional rigidity, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

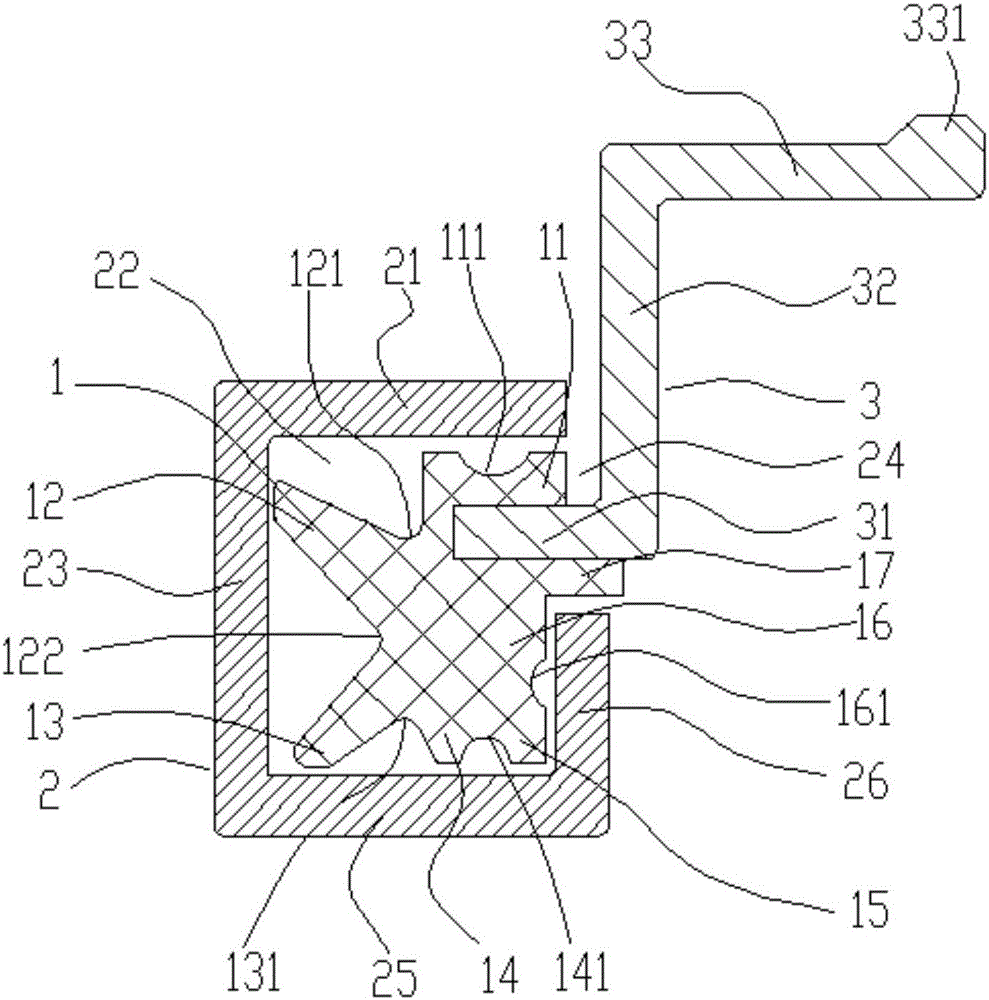

[0030] Such as figure 1 As shown, this embodiment provides a railway freight hub bearing sealing ring, including an outer frame 3 fixed on the bearing outer ring 4, an inner frame 2 fixed on the bearing inner ring 5, and an inner frame 2 and an outer frame 3 between the labyrinth seals 1, the inner skeleton 2 includes an inner skeleton inner ring 25 fixedly sleeved on the outer periphery of the bearing inner ring 5, an inner skeleton outer ring 21 set on the outer periphery of the inner skeleton inner ring 25, and fixedly connected to The annular outer plate 23 between the outer end of the inner frame inner ring 25 and the outer end of the inner frame outer ring 21 and the annular inner plate 26 fixedly connected to the inner end of the inner frame inner ring 25 and extending radially outward; the annular inner plate 26, The inner ring 25 of the inner skeleton, the annular outer plate 23 and the outer ring 21 of the inner skeleton form a semi-enclosed inner cavity 22, and an i...

Embodiment 2

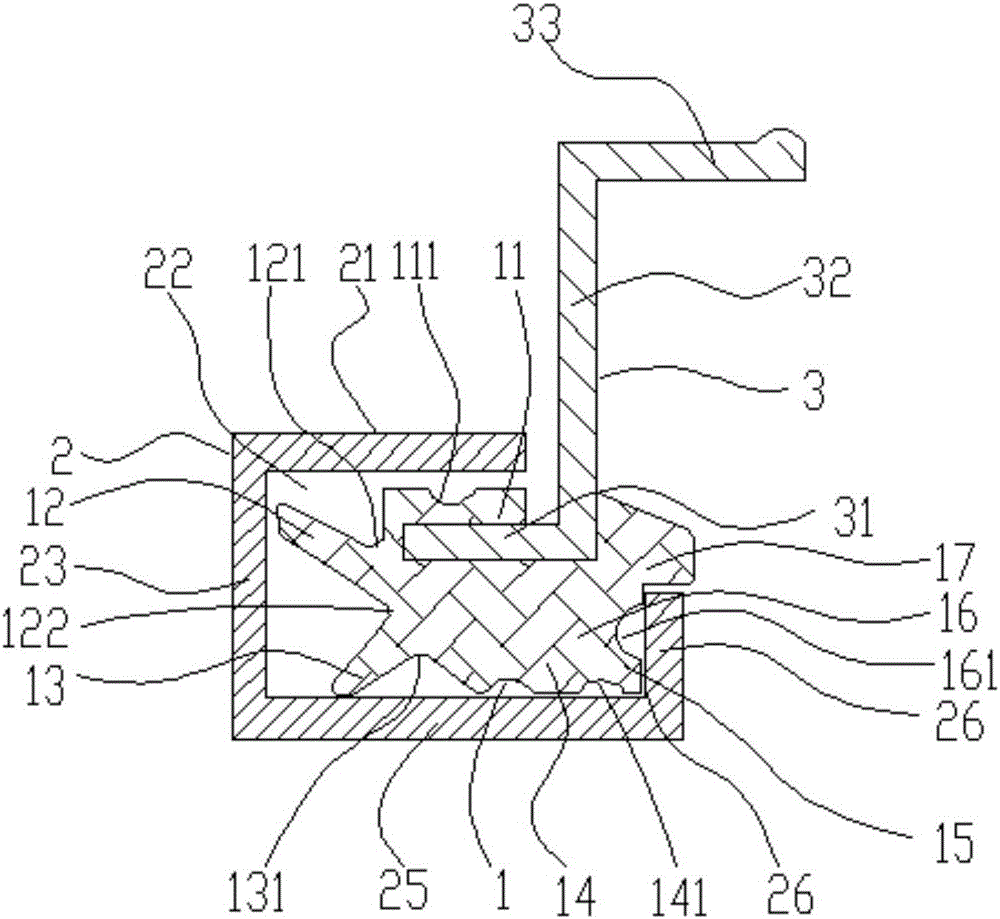

[0040] Such as figure 2 As shown, this embodiment provides a railway freight hub bearing sealing ring, including an outer frame 3 fixed on the bearing outer ring 4, an inner frame 2 fixed on the bearing inner ring 5, and an inner frame 2 and an outer frame 3 between the labyrinth seals 1, the inner skeleton 2 includes an inner skeleton inner ring 25 fixedly sleeved on the outer periphery of the bearing inner ring 5, an inner skeleton outer ring 21 set on the outer periphery of the inner skeleton inner ring 25, and fixedly connected to The annular outer plate 23 between the outer end of the inner frame inner ring 25 and the outer end of the inner frame outer ring 21 and the annular inner plate 26 fixedly connected to the inner end of the inner frame inner ring 25 and extending radially outward; the annular inner plate 26, The inner ring 25 of the inner skeleton, the annular outer plate 23 and the outer ring 21 of the inner skeleton form a semi-enclosed inner cavity 22, and an ...

Embodiment 3

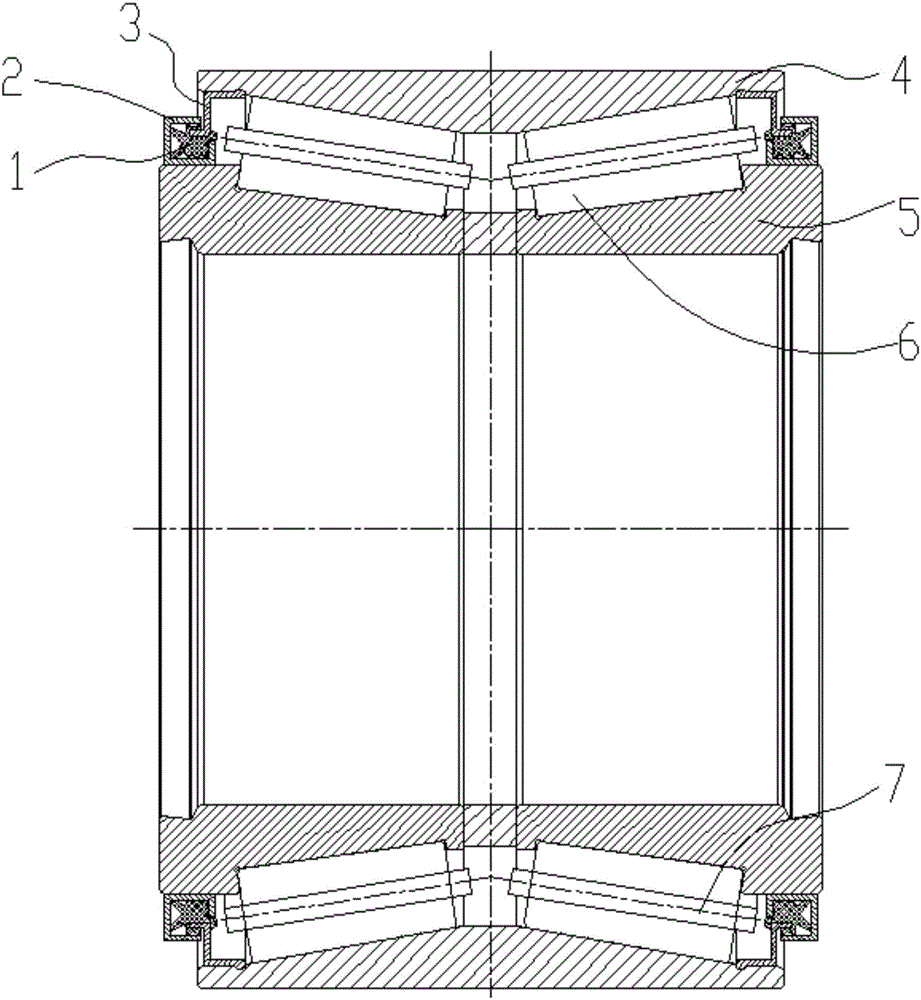

[0050] Such as image 3 As shown, this embodiment provides a bearing equipped with the bearing sealing ring in Embodiment 1 or Embodiment 2, including a bearing outer ring 4 with a tapered outer ring raceway surface, a tapered inner ring The bearing inner ring 5 on the raceway surface, several tapered rollers 6 placed in the raceway composed of the raceway surface of the outer ring and the raceway surface of the inner ring, and a cage for separating the tapered rollers 6 arranged in the raceway 7.

[0051] In this embodiment, in order to ensure the sealing function and effectively improve the composite bearing load of the bearing; the effective diameter of the tapered roller 6 is 25.745 mm, the total length of the tapered roller 6 is 57.03 mm, and the outer ring The cone angle of the raceway surface is 10°, and the cone angle of the raceway surface of the inner ring is 7.83°.

[0052] In order to position and install the sealing ring; the outer ring 33 of the exoskeleton is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com