A brake cylinder with force amplification function

A technology of amplifying function and brake cylinder, applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the problems of reducing the clearance of the disc and difficult to control the elastic deformation, so as to avoid the gradual reduction of the clearance, Achieving easy, high parking force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

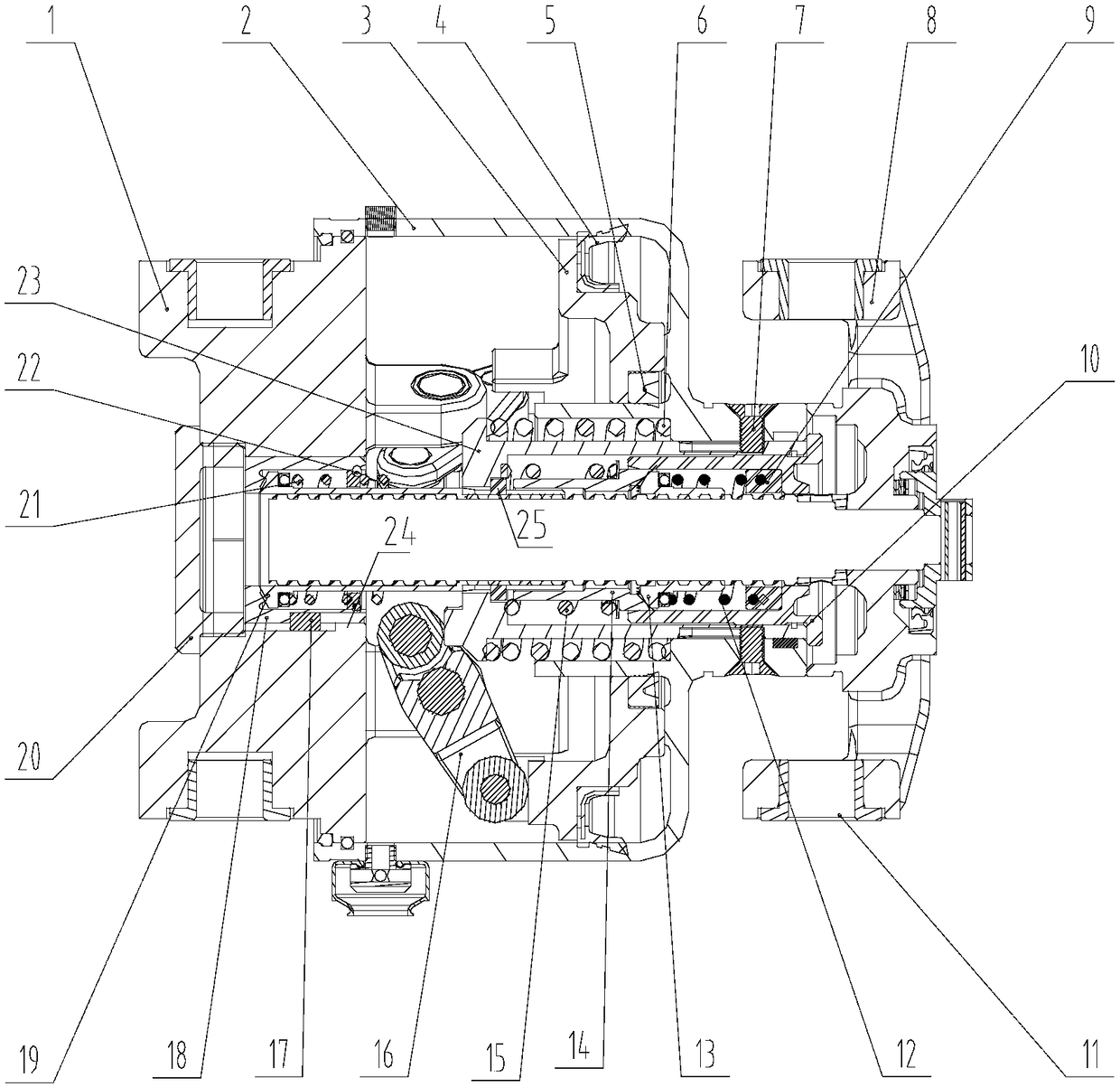

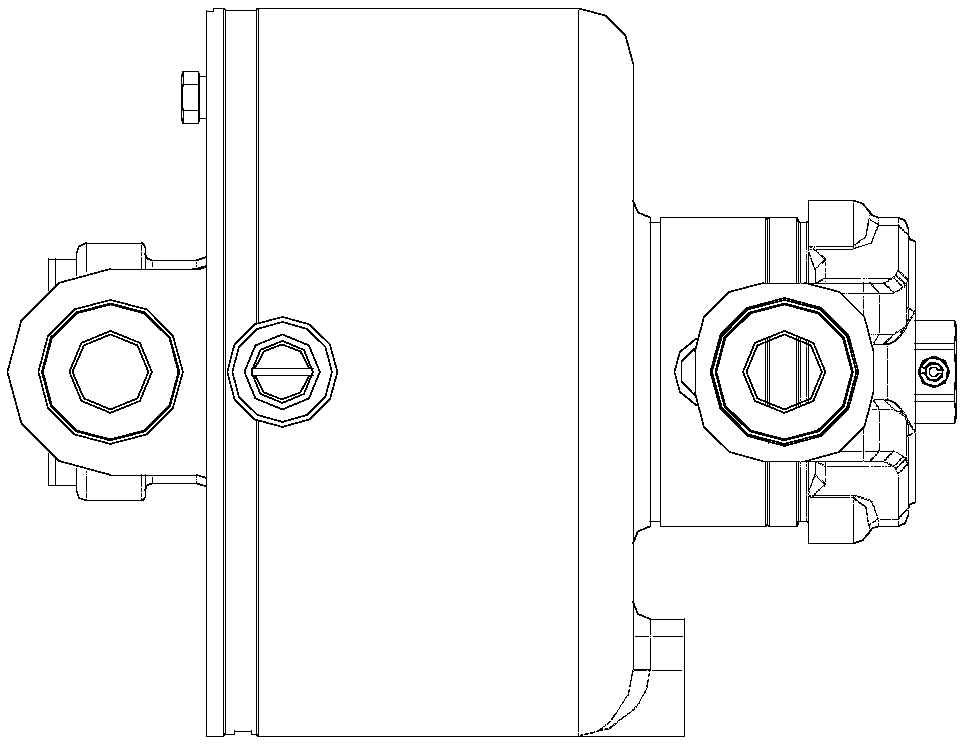

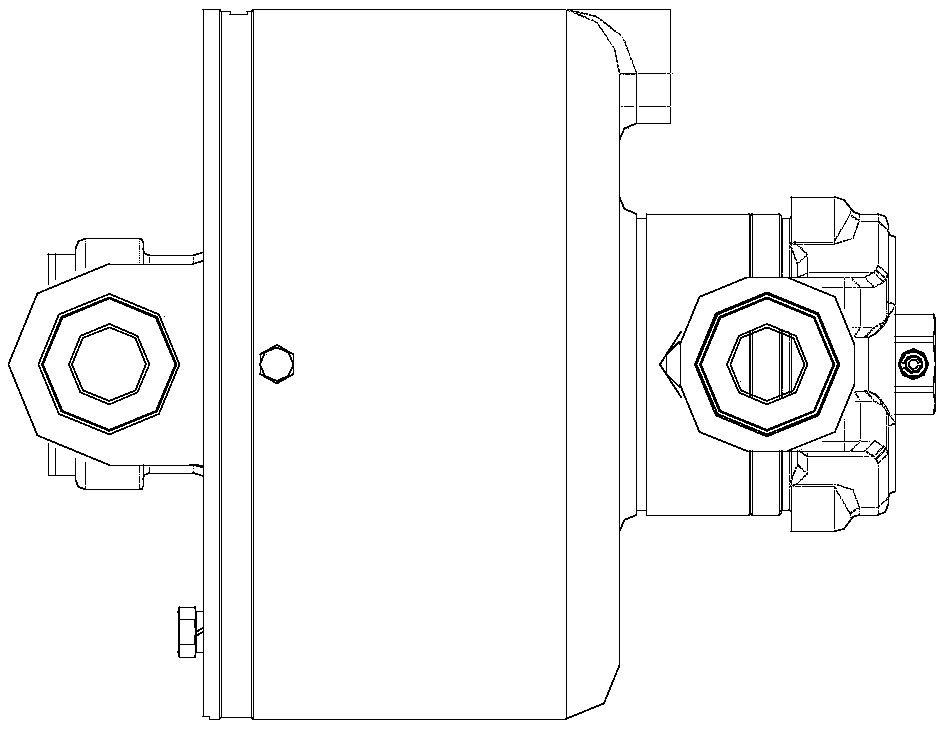

[0028] The brake cylinder with force amplification function of this embodiment has a structure such as Figure 1 to Figure 5 As shown, it includes a cylinder body 1 and a cylinder head 2 fixedly sleeved on one end of the cylinder body 1. The cylinder body 1 has an oil circuit interface and an air inlet. The cylinder body 1 has a piston 3, a guide spring 12, a guide nut 13, The taper sleeve 14, the adjusting shaft member 8 and the gap adjusting nut member, wherein the adjusting shaft member 8 includes an adjusting shaft, the rear end of the adjusting shaft is inserted into the cavity of the cylinder body 1, the front end is inserted into the shaft hole of the yoke, and the yoke The upper and lower ends of the upper and lower ends respectively have extensions extending inward, and bushings 11 are provided on the extensions, bellows can also be arranged between the cylinder head 2 and the yoke, the adjustment shaft has external threads, and the guide nut 13 has external threads. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com