Equipment and technology for burr removing of corrugated tube sieve pores

A technology of burr removal and bellows, applied in the field of machining, to achieve the effects of good polishing performance, improved service life and stability, and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

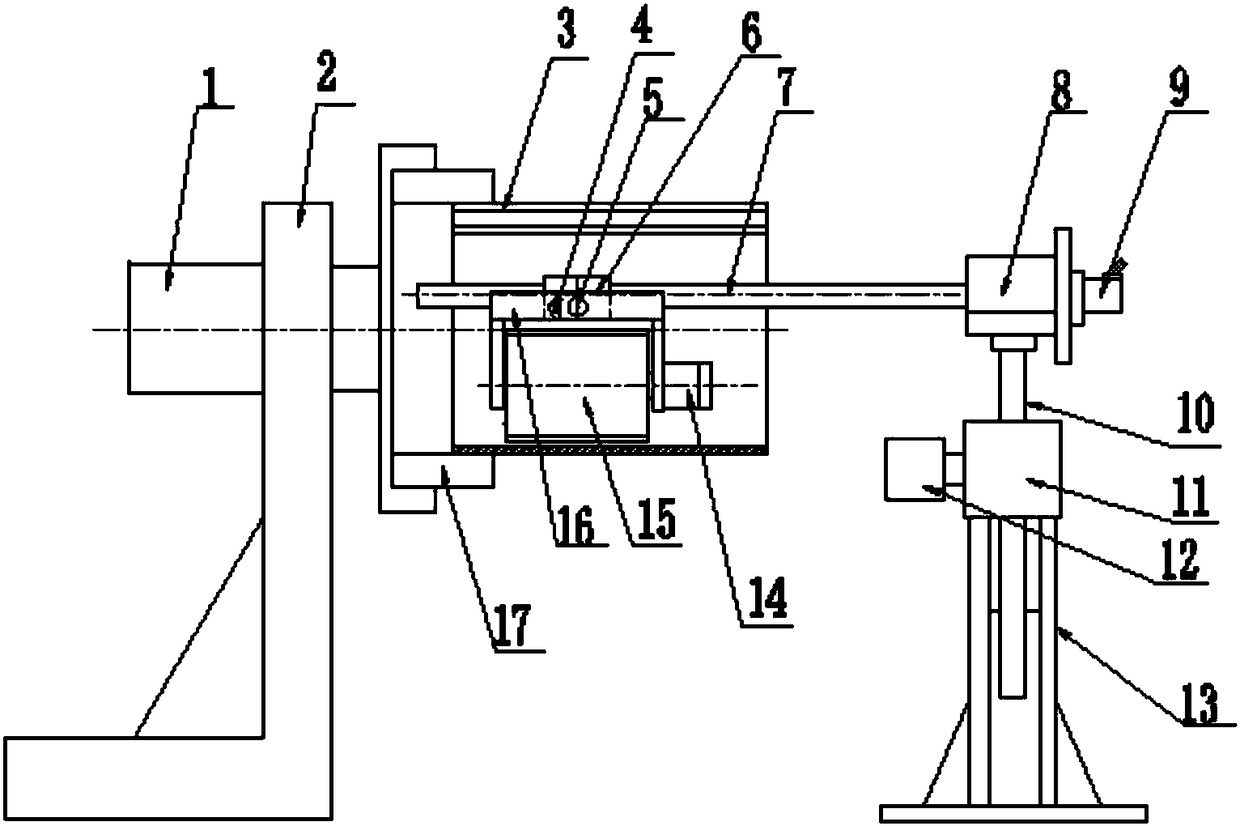

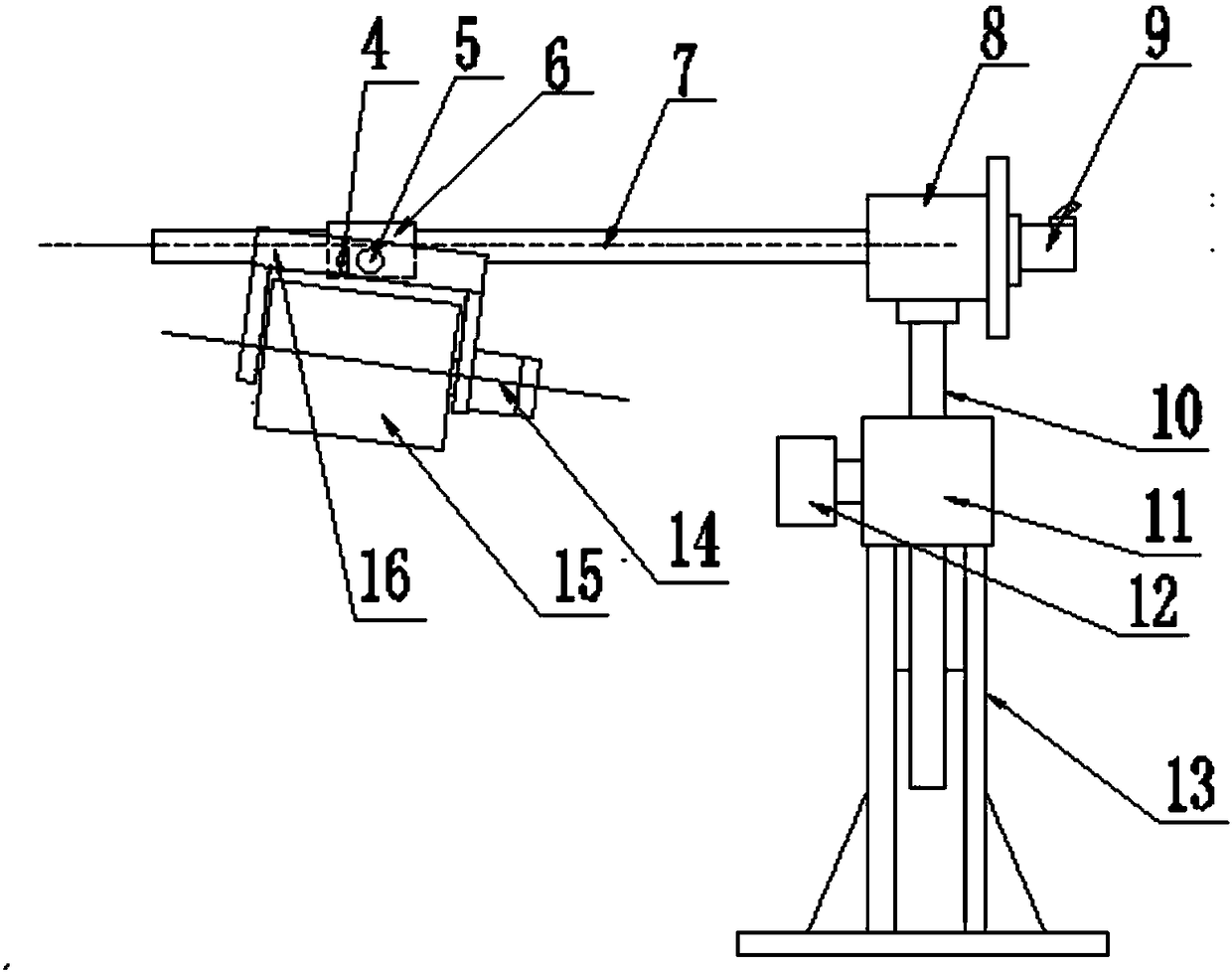

Embodiment 1

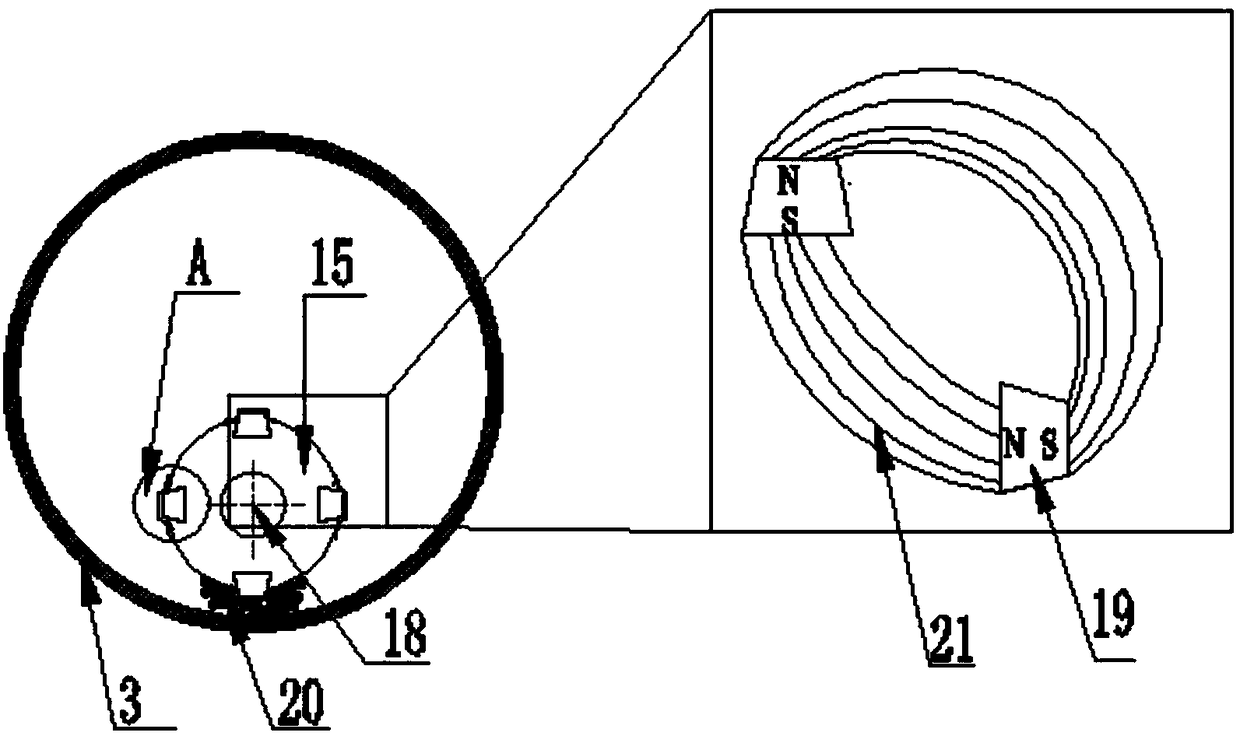

[0036] In this embodiment, the length of the corrugated cylinder is 1000mm, and the diameter is 650mm; the equipment for removing the burrs from the sieve holes of the corrugated cylinder is composed as follows: the corrugated cylinder rotating motor 1 is fixed on the fixed bracket A2 through bolt connection, the corrugated cylinder rotating motor 1 axis and the corrugated cylinder The clamps 17 are concentric and fixedly connected. When the corrugated tube clamp 17 clamps the corrugated tube 3, the corrugated tube rotating motor 1 is powered on, and the corrugated tube clamp 17 clamps the corrugated tube 3 to rotate positively and negatively, and the direction of rotation is the same as that of the magnetic grinding head. On the contrary, it is beneficial to improve the grinding effect. The grinding head tilt adjustment shaft 5 can adjust the angle between the axis of the magnetic permeable iron ring 15 and the horizontal direction. Adjust the axis of the magnetically permeab...

Embodiment 2

[0040] The corrugated cylinder processed in this embodiment has a length of 1200mm and a diameter of 800mm; The rotational speed of the grinding head drive motor 14 is 600r / min, and the reversing speed of the bellows 3 is 400r / min; the lateral linear movement speed of the grinding head is 6cm / min; the abrasive composition used is Al 2 o 3 and Fe sintered abrasives, adding oily grinding fluid to the abrasives. Grind and change the abrasive material every 20 minutes. The abrasive material diameter is 20 meshes; the grinding time is 45 minutes; the magnetically conductive iron ring 15 has a diameter of 30mm and a length of 130mm; the gap between the trapezoidal magnet 19 and the corrugated cylinder 3 is 4mm.

Embodiment 3

[0042] The corrugated cylinder processed in this embodiment is a conical corrugated cylinder with a length of 800mm and diameters of both ends of the corrugated cylinder of 400mm and 600mm; Adjust the angle between the axis of the magnetically permeable iron ring 15 and the horizontal direction so that the magnetically permeable iron ring 15 is parallel to the wall of the conical corrugated cylinder 3; the grinding head support 16 is fixed and locked by the inclination angle locking screw 4 . The grinding head traverse motor 9 drives the magnetic grinding head to move horizontally in the corrugated cylinder 3; the longitudinal linear module motor 12 drives the magnetic grinding head to move up and down; the distance between the trapezoidal magnet 19 and the cylinder wall is kept constant, making the grinding of the surface of the corrugated cylinder 3 easier Uniform and dense.

[0043] Grinding head driving motor 14 rotating speed is 800r / min, corrugated tube 3 reverse speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com