Low torque natural gas fixed ball valve

A technology for fixing ball valves and natural gas, applied in valve details, valve devices, valve shell structures, etc., can solve problems such as insufficient internal structure, complex structure of fixed ball valves, increased valve stem torque, etc., to achieve convenient operation and production The effect of creating and reducing torque force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

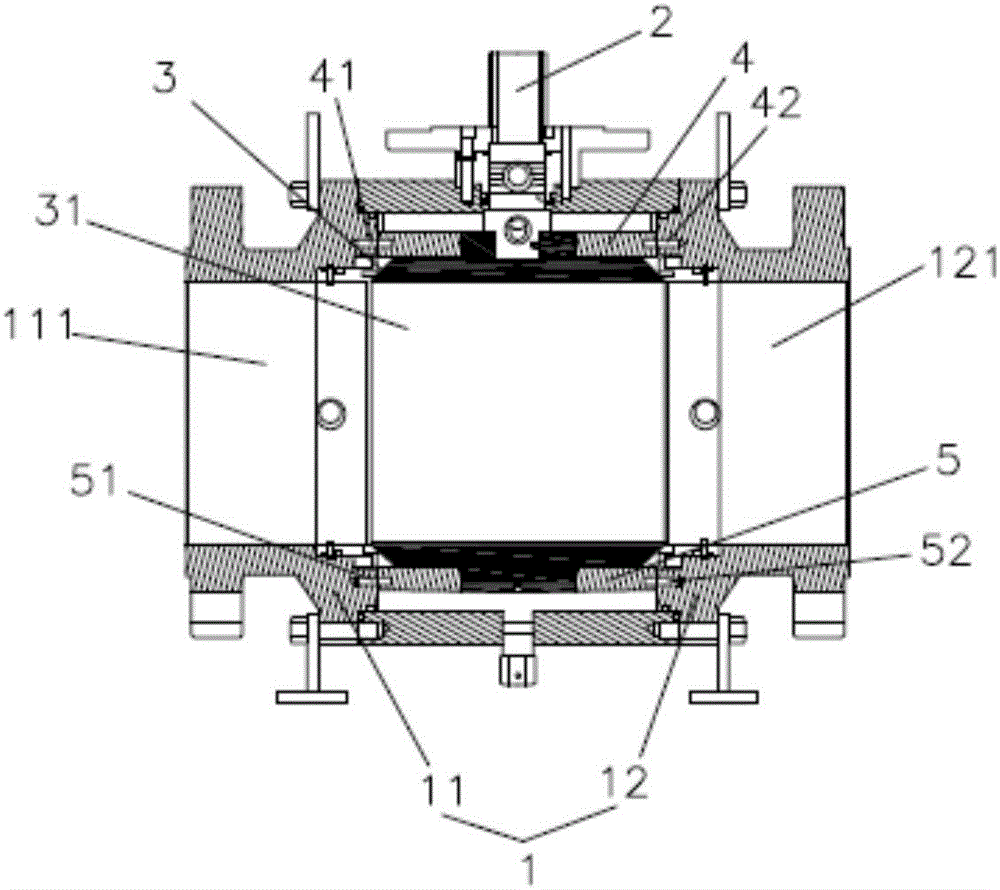

[0014] Such as figure 1 As shown, a low-torque natural gas fixed ball valve includes a valve body 1 and a valve stem 2. The valve body 1 is divided into a left valve body 11, an intermediate body 3 and a right valve body 12, between the left valve body 11 and the right valve body 12 Connected by the intermediate body 3, the left valve body 11 is provided with a left fluid channel 111, the right valve body 12 is provided with a right fluid channel 121, and the intermediate body 3 is provided with a middle fluid channel 31, the middle fluid channel 31, left The diameters of the fluid channel 111 and the right fluid channel 121 are the same, and the design is beneficial to reduce the thrust from the fluid, thereby reducing the torque force, and facilitating people's operation. The middle fluid channel 31 of the intermediate body 3 rotates when the intermediate body 3 rotates. The left fluid passage 111 of the left valve body 11 and the right fluid passage 121 of the right valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com