Built-in sensor and method for monitoring internal strain of concrete structure

A concrete structure and sensor technology, applied in the direction of electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve problems such as the health impact of concrete structures, achieve good deformation recovery performance, ensure accuracy, and accurately monitor the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

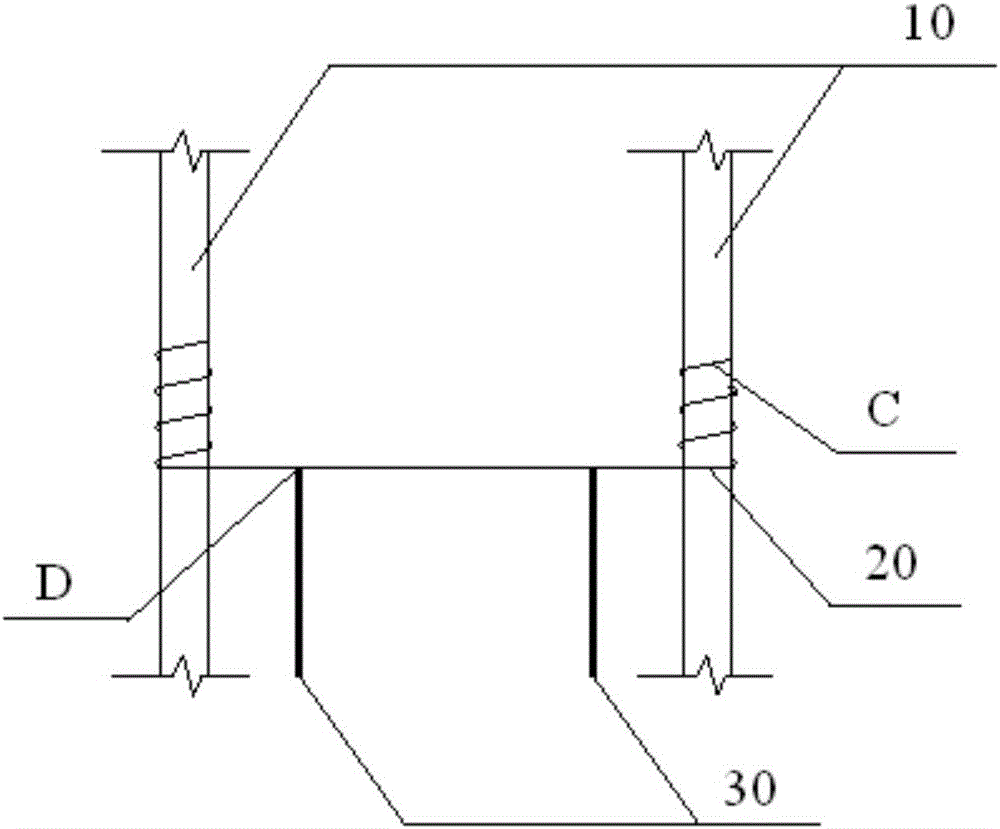

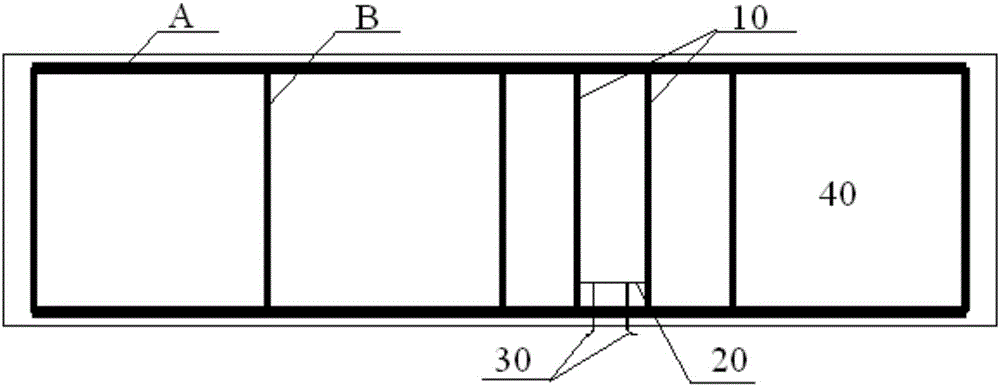

[0025] combine figure 1 and figure 2 As shown, this embodiment discloses a built-in sensor for measuring the internal strain of the concrete structure 40 . The built-in sensor includes: a pair of fixing parts 10, fixed in the concrete structure 40; memory alloy sensing wire 20, arranged between the pair of fixing parts 10 and in a tensioned state, and its two ends are respectively connected with the pair of fixing parts 10 , located in the concrete structure 40; a pair of wires 30, a pair of wires 30 are connected to the memory alloy sensing wire 20, and a pair of wires 30 are respectively located at the two ends of the memory alloy sensing wire 20, the first part of the wire 30 is located in the concrete In the structure 40, the second part protrudes from the concrete structure 40, and the second part of the wire 30 is used for connection with the monitor.

[0026] In the built-in sensor in this embodiment, the internal strain of the concrete structure 40 is monitored thro...

Embodiment 2

[0032] The invention also discloses a method for monitoring the internal strain of the concrete structure through the above-mentioned built-in sensor: a pair of fixing parts are arranged inside the concrete structure, a memory alloy sensing wire is arranged between the pair of fixing parts, and the memory alloy sensing wire The two ends are respectively fixed on a pair of fixing parts, and the memory alloy sensing wire is tensioned between the pair of fixing parts, the wire is connected to the memory alloy sensing wire, and the wire is extended out of the concrete structure, the concrete structure When the structure of the memory alloy sensing wire changes, the memory alloy sensing wire deforms, and the resistance value of the memory alloy sensing wire changes. The "strain-resistivity" relationship judges the internal strain of the concrete structure.

[0033] After one monitoring is finished, before the next monitoring, the memory alloy sensor is heated until the shape of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com