Encapsulating method of COB (chip-on-board) display module and display module

An encapsulation method and technology for display modules, which are used in identification devices, instruments, etc., can solve the problems of inability to completely avoid light mixing, ineffective absorption by light-shielding layers, uneven filling, etc., to avoid light mixing, reduce spacing, and reduce injection. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

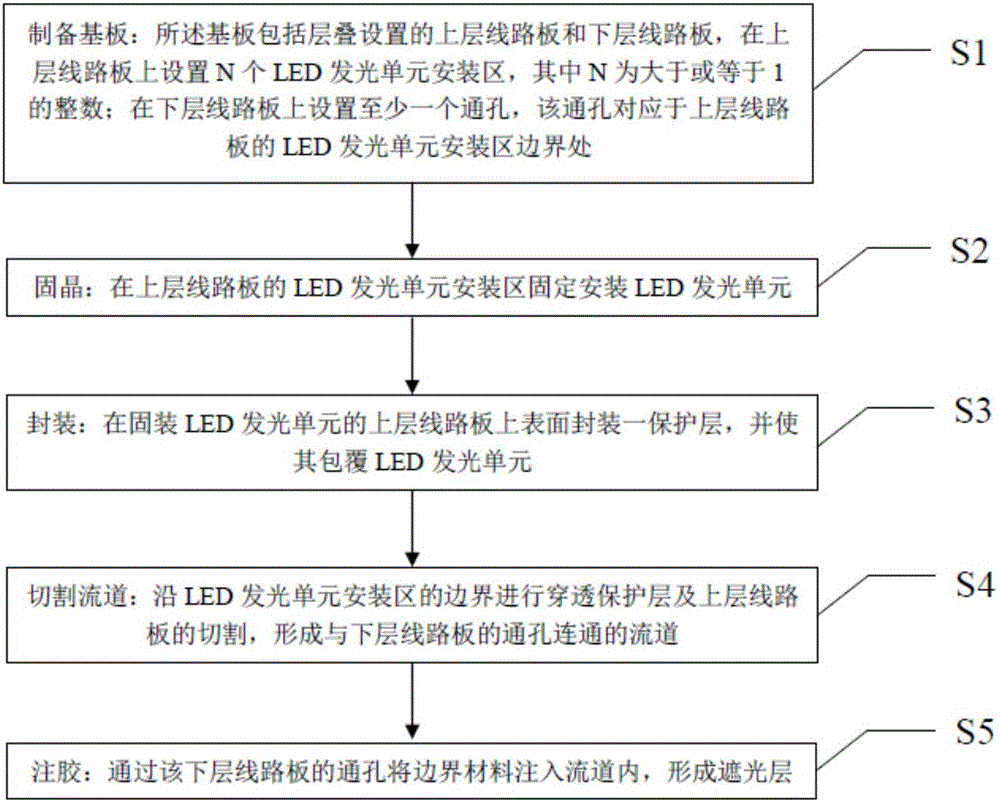

[0044] see figure 2 , which is a flow chart of the packaging method of the COB display module of the present invention, the packaging structure of the COB display module of the present invention can be realized through the following steps:

[0045] Step S1 : Prepare the substrate 100 .

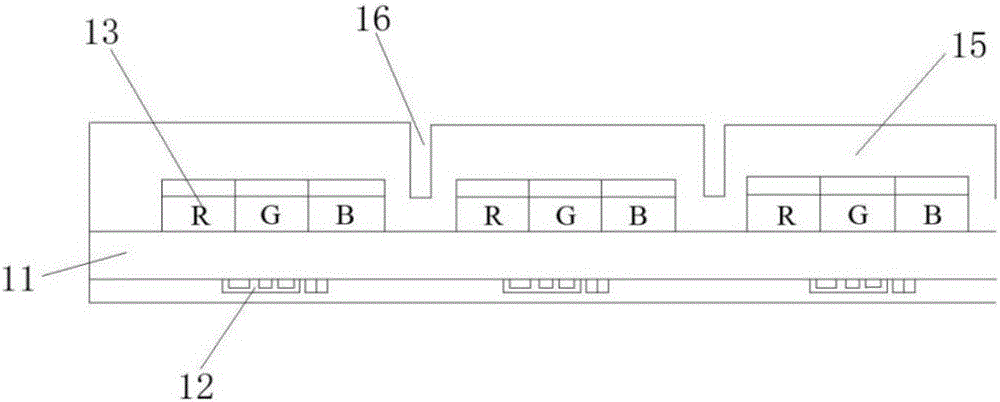

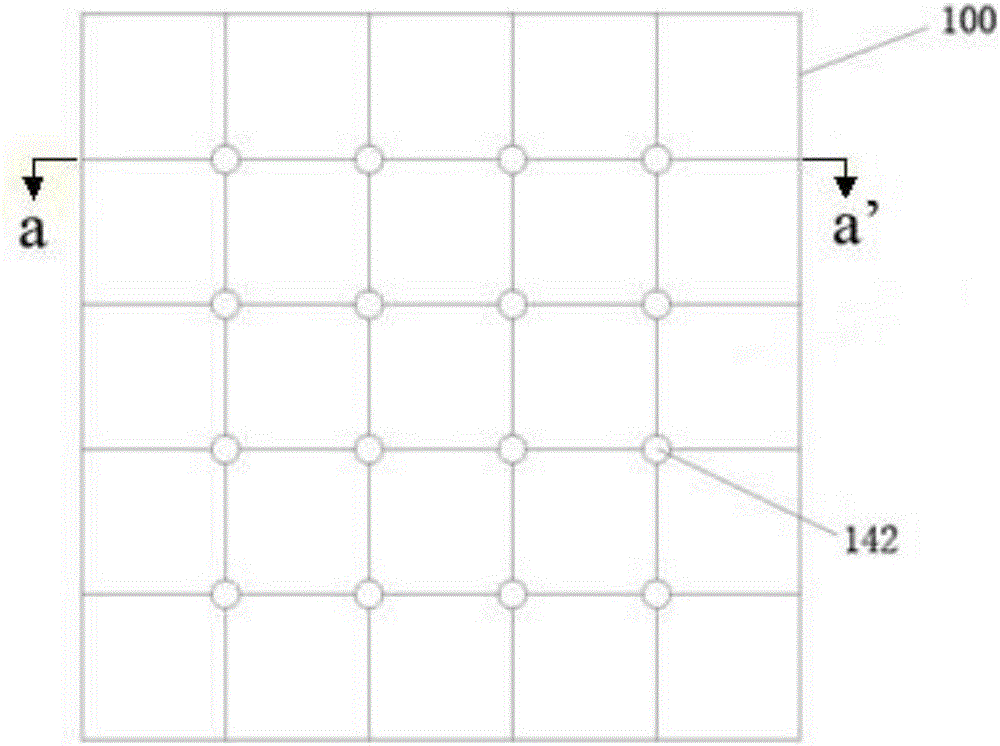

[0046] see image 3 with Figure 4 , which are respectively a bottom plan view and a cross-sectional view of the substrate 100 in step S1 of the present invention. In this embodiment, the substrate 100 includes an upper layer circuit board 120 and a lower layer circuit board 140 that are stacked. Both the upper layer circuit board 120 and the lower layer circuit board 140 may be single-layer circuit boards or multi-layer circuit boards. On the upper circuit board 120, N LED light-emitting unit installation areas 122 for arranging N groups of light-emitting units are arranged, wherein N is an integer greater than or equal to 1. The LED lighting unit installation area 122 set in this step i...

Embodiment 2

[0060] The content of this embodiment is basically the same as that of Embodiment 1, the difference lies in the step S5 of the encapsulation method of the COB display module and the structure of the COB display module.

[0061] In step S5, the boundary material is injected using a mold provided with grooves, and the substrate 100 is placed in the mold, wherein the bottom surface of the lower circuit board 140 is in contact with the grooves of the mold. In the injection process, the boundary material is injected from the mold, and a certain injection pressure is used to make the boundary material pass through the groove on the mold from the bottom of the lower circuit board 140, distribute into the through hole 142 and flow into the flow channel 124, and in the lower circuit board 140. The bottom surface of the plate 140 forms a balancing layer 500 corresponding to the shape of the mold groove. Through this injection method, the multi-channel injection of the boundary material ...

Embodiment 3

[0064] The content of this embodiment is basically the same as that of Embodiment 1, the difference lies in the steps S1 and S5 of the encapsulation method of the COB display module and the structure of the COB display module.

[0065] In step S1, a channel is further provided on the bottom surface of the lower circuit board 140 by means of a mold or cutting, and the channel communicates with the through hole on the lower circuit board at the same time, and its shape and depth can be adjusted according to the actual design. The shape of the channel is grid-like, and may also be dendrite-like or the like.

[0066] In step S5, the boundary material is injected into the channel, and the boundary material is distributed into the through hole through the channel, so as to form a balance layer embedded in the channel and the through hole on the bottom surface of the lower circuit board 140, through the The method obtained is a COB display module formed on both sides of the boundary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com