Release liquid injection tooling for encapsulating high-voltage IGBT modules

A tooling and high-voltage technology, applied in the field of release fluid injection tooling for high-voltage IGBT module packaging, can solve the problems of injection and release fluid that has not yet appeared, and achieve the effect of reducing time, reducing technical level and experience, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

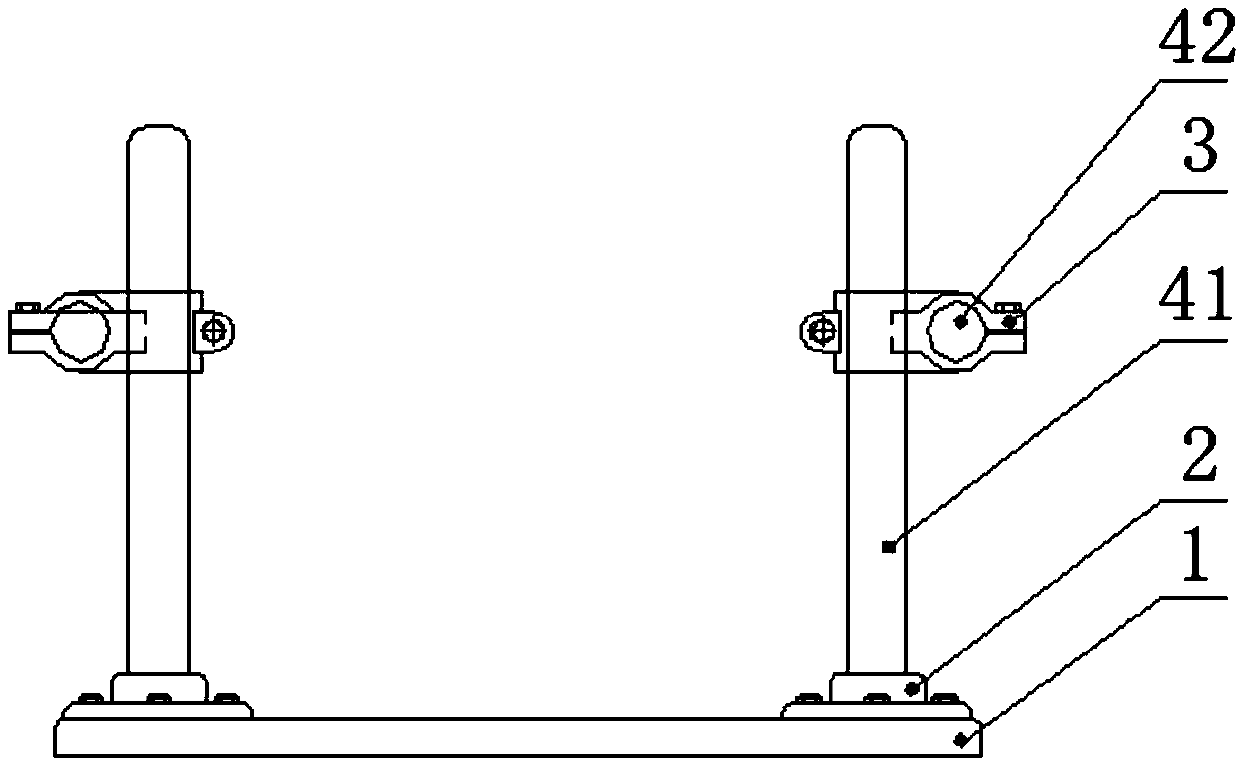

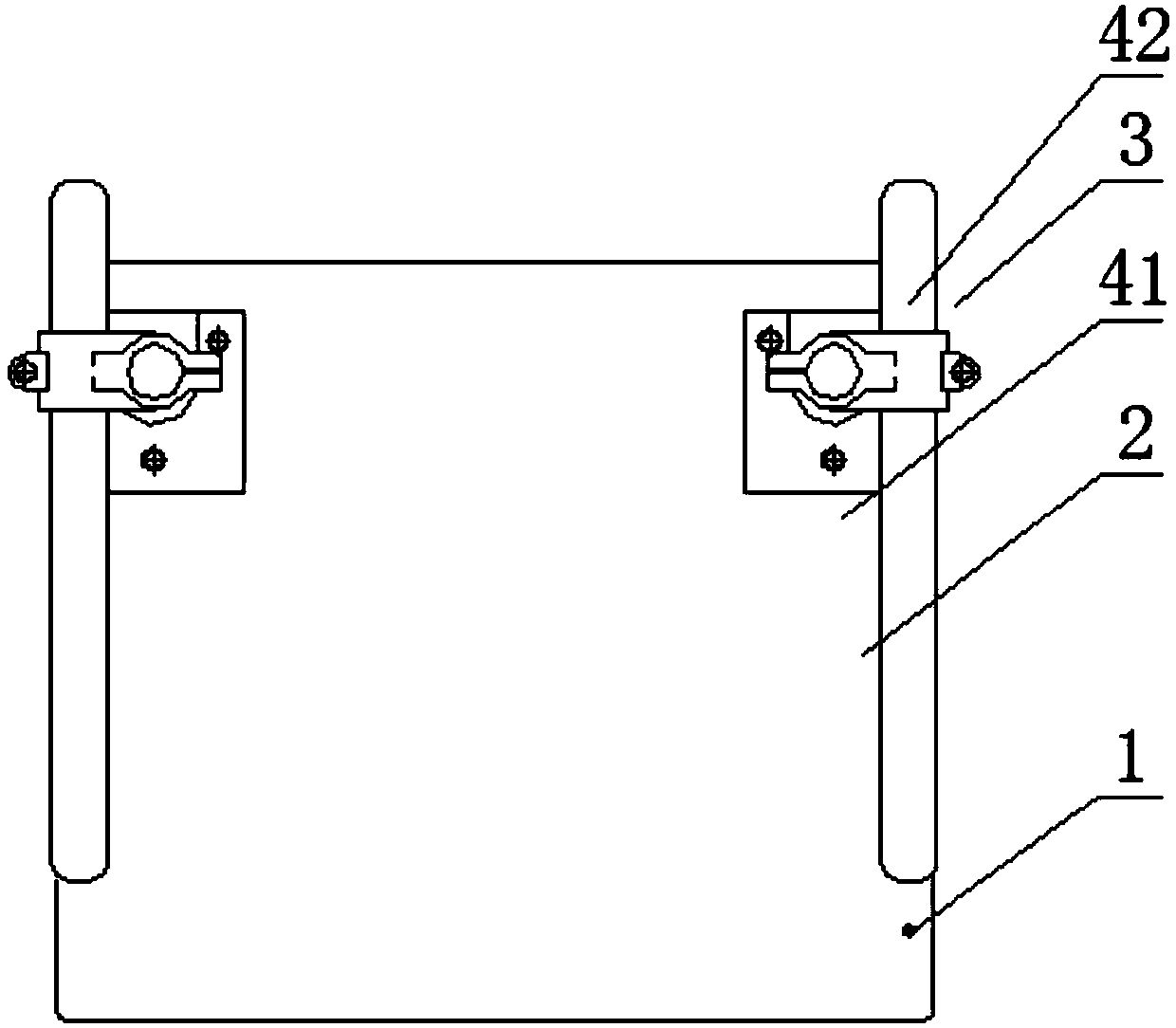

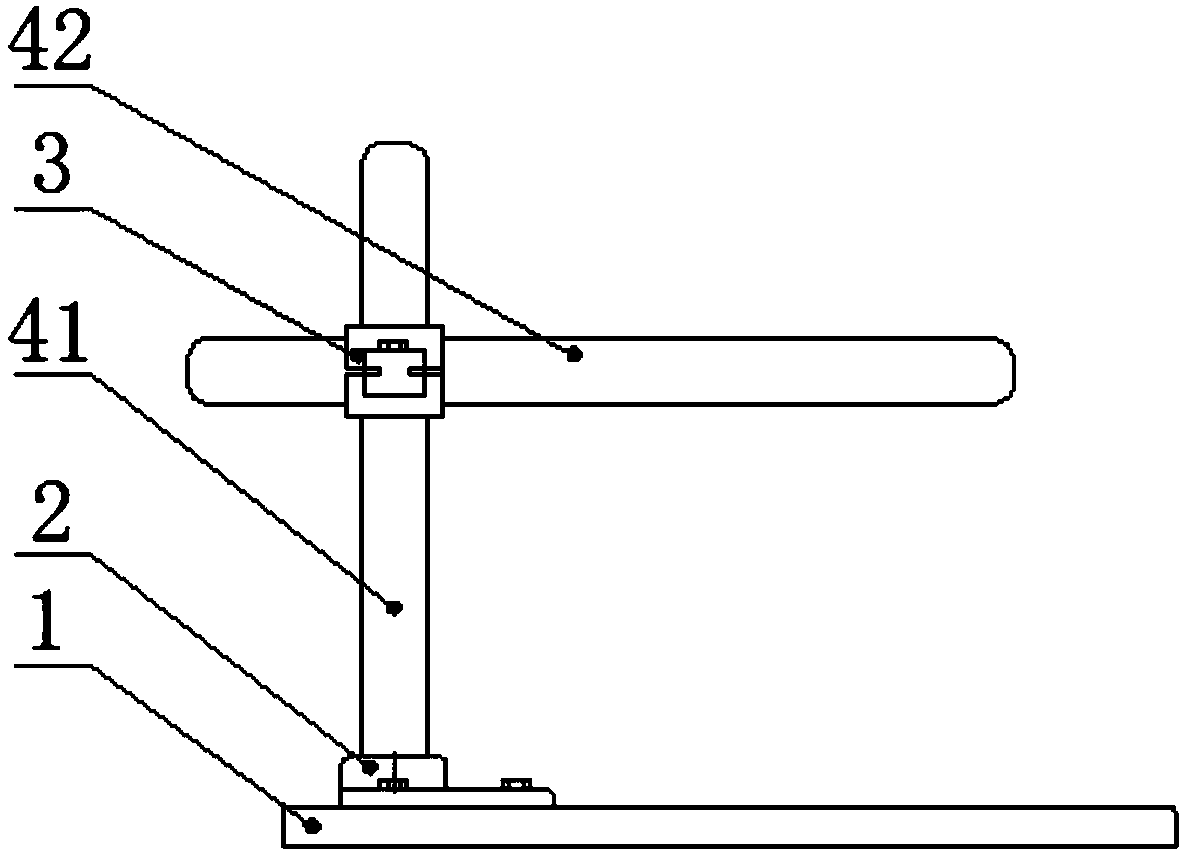

[0017] The invention discloses a release liquid injection tool for packaging high-voltage IGBT modules above 4500V, such as figure 1 , figure 2 and image 3 As shown, the injection tooling includes four parts: the bottom plate 1, the card seat 2, the buckle 3 and the support rod, wherein the support rod includes a vertical support rod 41 and a horizontal support rod 42, and the vertical support rod 41 is connected with the horizontal support rod. The rods 42 are connected by buckles 3, the vertical support rods 41 are connected with the bottom plate 1 by the clamp 2, and the horizontal support rods 42 are installed with a glue injection head and a glue suction head of the release liquid injection device. It should be noted that the release liquid injection equipment is an existing, conventional, and commercially available equipment.

[0018] As a preferred technical solution, the bottom plate 1 is a hard plate. The present invention has no strict requirements on the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com