Flat single shaft tracking support

A flat uniaxial and bearing technology, applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of reducing structural stability, fatigue life cannot be guaranteed, and installation work intensity is high, so as to improve fatigue Long life, reduced vibration, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

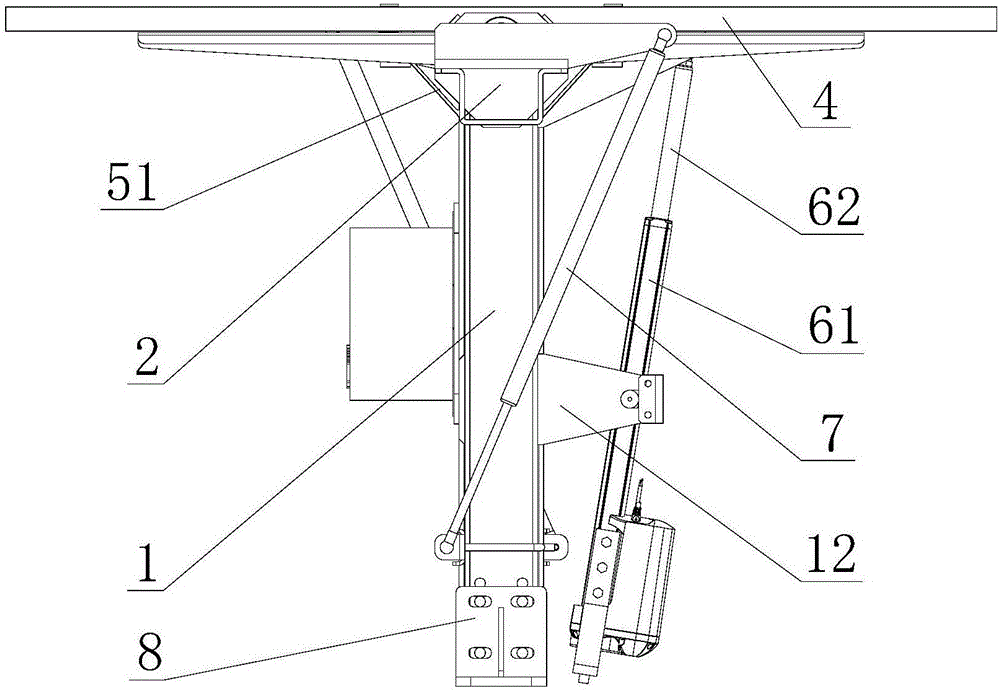

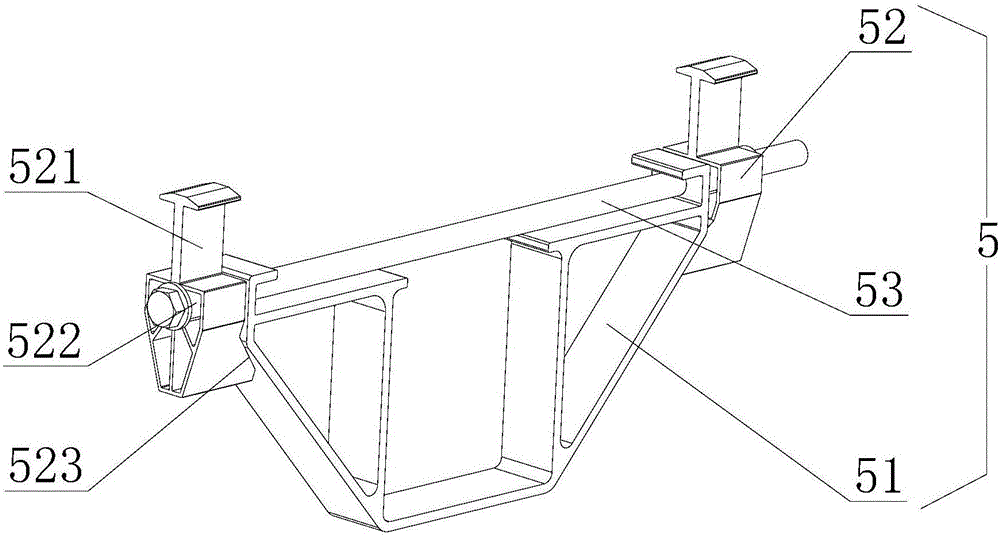

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] see Figure 1-6 As shown, the above-mentioned flat uniaxial tracking bracket includes a support column 1, a bearing assembly groove 11 is opened on the top of the support column 1, a base 8 is provided at the bottom of the support column 1, and a fixed support column 1 is adjustable up and down. Set in the base 8. The column is a standard rectangular tube, and the bottom of the column is provided with multiple threaded holes along the vertical direction, and is fixed on the base 8 by bolts.

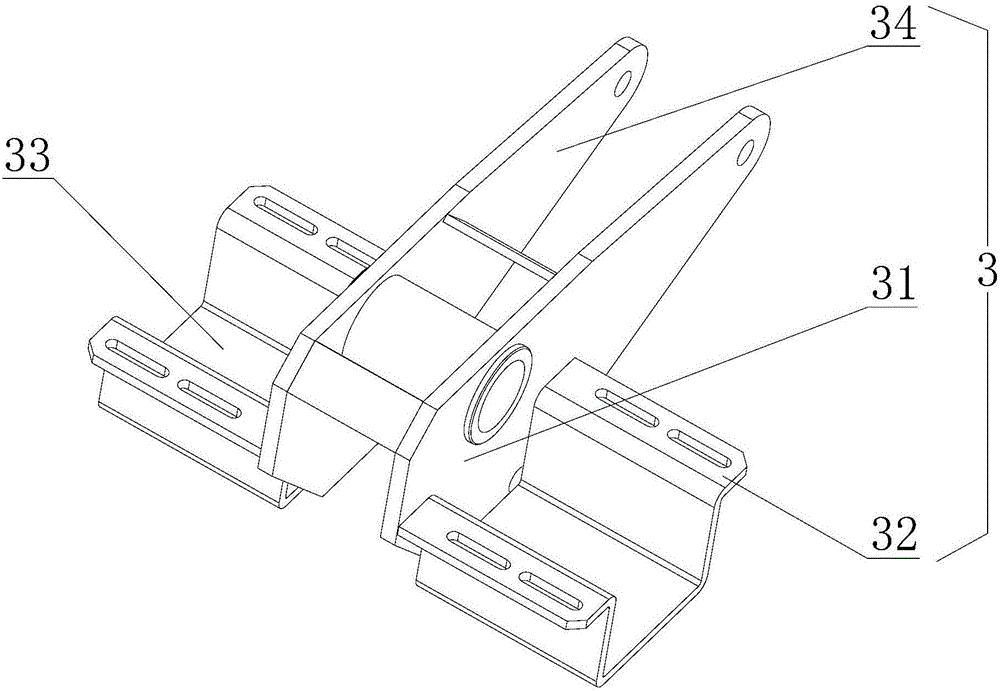

[0033] The above-mentioned bearing fitting groove 11 is semicircular, and the eccentric bearing 3 is installed in the bearing fitting groove 11 . The main beam 2 is fixed in the eccentric bearing 3 . The main beam 2 is erected between two supporting columns 1 along the horizontal direction. The eccentric bearing 3 includes a bearing body 31 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com