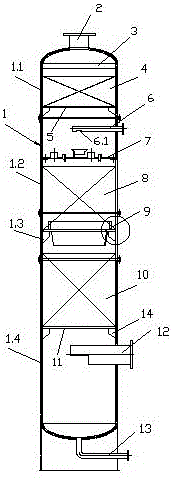

Absorption tower

A technology of absorption tower and tower body, which is applied in the field of sewage treatment, can solve problems such as high tower body, difficult installation and maintenance, and unsmooth gas outlet, and achieve the effects of uniform distribution of gas and liquid, convenient installation and maintenance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

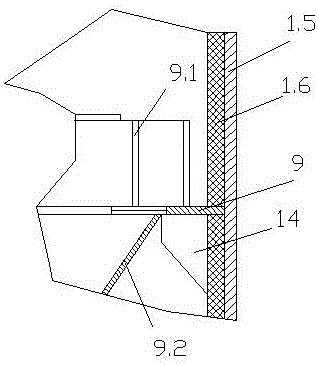

[0013] Embodiment 1: An absorption tower includes a vertical tower body 1, the tower body 1 is spliced by four sections of cylinders, the four sections of cylinders are sealed and connected by connecting flanges, and the top end of the first section of cylinders 1.1 is sealed An air outlet 2 is provided on the head, a demister 3 is arranged under the air outlet 2, a first layer of filter material 4 is arranged under the demister 3, the first layer of filter material 4 is arranged on the first bracket 5, and the second A concentrated sulfuric acid inlet pipe 6 is arranged on the top side wall of the section cylinder 1.2, a distribution plate 7 is arranged below the concentrated sulfuric acid inlet pipe 6, a second layer of filter material 8 is arranged under the distribution plate 7, and a second tray for the second layer of filter material 8 The frame 9 is arranged near the top of the third section cylinder 1.3, the upper surface of the second bracket 9 is provided with a gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com