Ergonomic assembly process material shelf

An ergonomics and assembly process technology, applied in the field of material racks, can solve the problems of consuming a lot of energy and time, consuming time and energy, positioning and grasping errors, etc., to save grasping time, improve operating speed, and reduce physical strength The effect of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

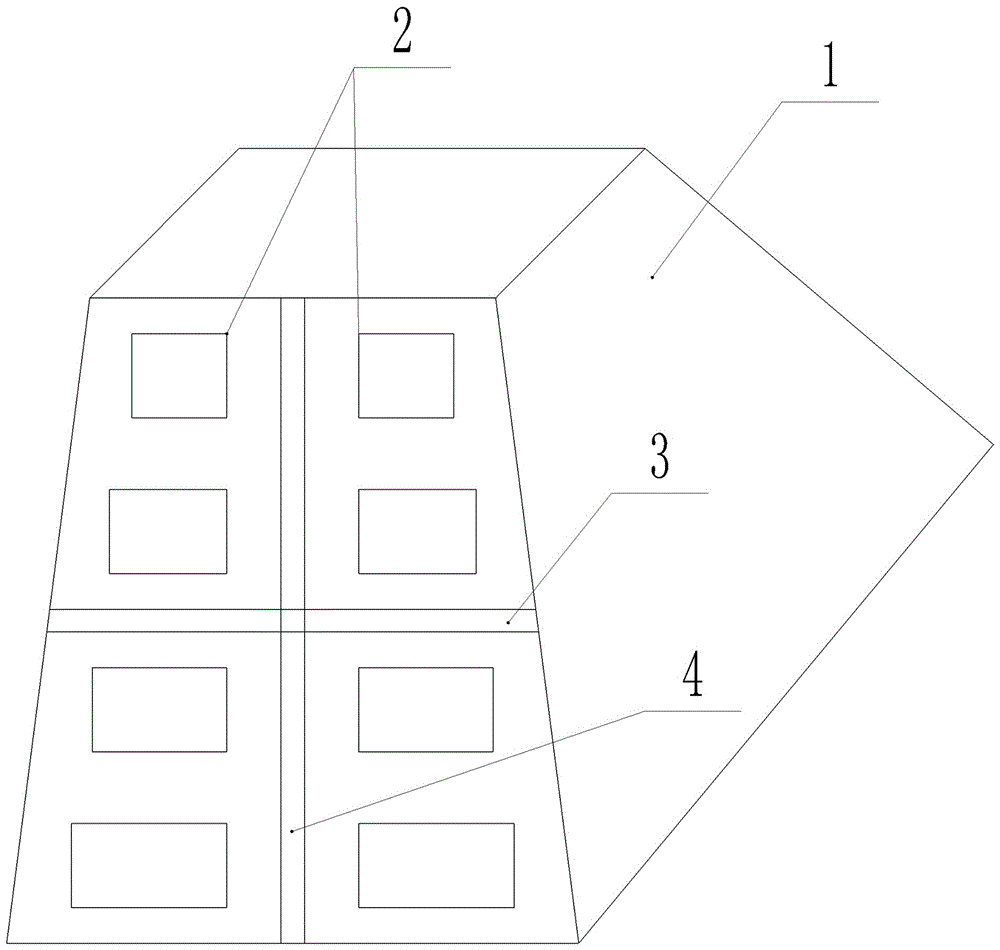

[0024] refer to figure 1 , an ergonomic assembly process material rack comprising

[0025] A material rack 1, the material rack 1 is in the shape of a prism;

[0026] Material box 2, described material box 2 is arranged in the material frame 1, and the extraction end of material box 2 is positioned at the front side of material frame 1; Described material box 2 quantity is eight, and the extraction end of eight material boxes 2 is divided into Two rows are evenly distributed on the front side of the material rack 1;

[0027] Transverse partition 3, which is horizontally arranged on the front side of the material rack 1, and the horizontal partition 3 divides the eight material boxes 2 into upper and lower parts equally;

[0028] Median partition 4, said longitudinal partition 4 is longitudinally arranged on the front side of material frame 1, and medial partition 4 divides eight material boxes 2 equally into left and right two parts;

[0029] The transverse partition 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com