Wall-climbing robot with tunnel wall adsorption function and inspection method for water diversion and power generation tunnel of hydropower station

A wall-climbing robot and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of not being able to stick to the wall for inspection, and achieve the effects of high inspection efficiency, true and comprehensive information, and a large inspection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

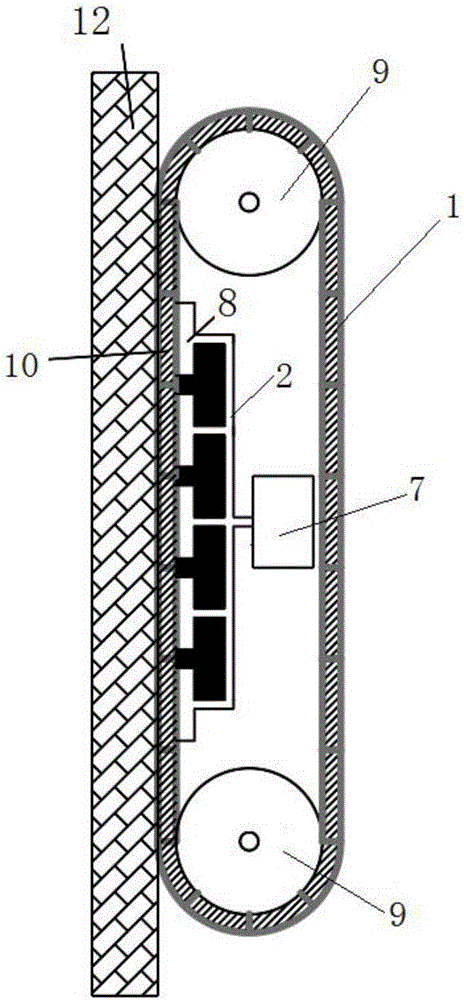

[0036] Such as figure 1 As shown, an adsorption wall-climbing robot for inspection of underwater caverns and steep walls includes an adsorption device for adsorbing the robot on the cave wall 12. The adsorption device includes an adsorption crawler 1, which is a whole non-splicing Plastic tracks. The inner side of the adsorption track 1 is in communication with the negative pressure chamber 2, and the negative pressure chamber 2 is connected with the water pump 7.

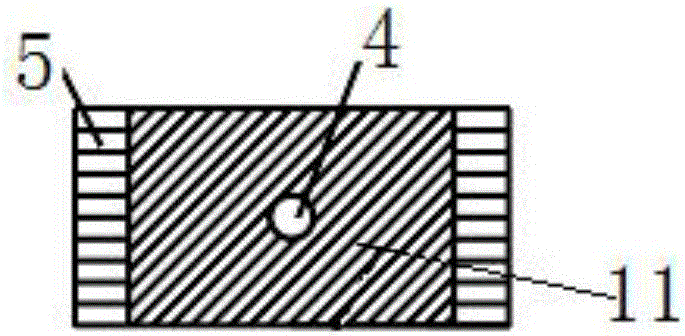

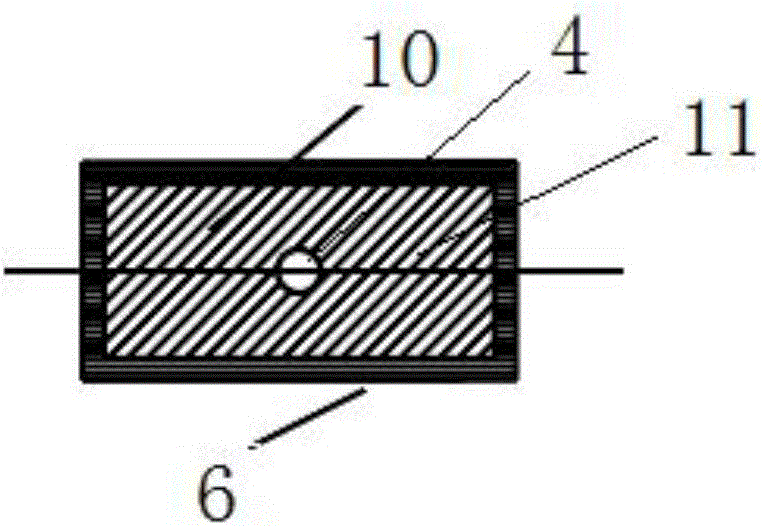

[0037] Such as figure 2 , 3 , 4 and 5, the adsorption track 1 includes several connected adsorption chamber units 10, the outer edge of the adsorption chamber unit 10 is provided with a closed adsorption skirt 6, the outline of the adsorption skirt 6 is rectangular, and the inner side of the adsorption skirt 6 is an adsorption Chamber 3, there is a smooth surface 11 inside the adsorption chamber 3, and there is a water absorption hole 4 on the smooth surface 10, the water absorption hole 4 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com