Double-face automatic printing method for lithium ion power battery ceramic sealing rings

A ceramic sealing ring, power battery technology, applied in printing, sealing materials, secondary batteries and other directions, can solve the problems of affecting quality, difficult to grasp thickness, affecting the thickness of metallized molybdenum-manganese printing, etc., to ensure consistency and ensure sealing The effect of stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

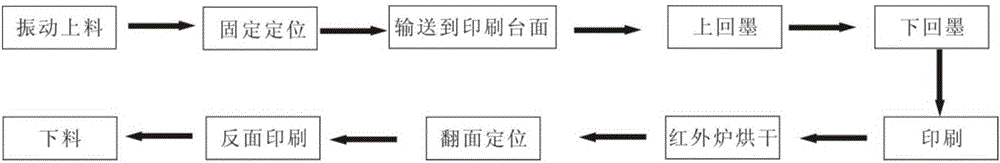

[0026] Such as Figure 1-3 As shown, a double-sided automatic printing method for a lithium-ion power battery ceramic sealing ring provided by the present invention comprises the following steps:

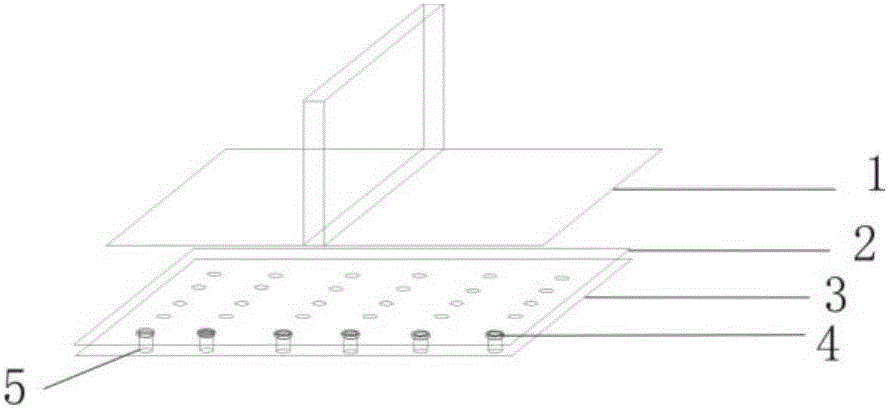

[0027] Step (1): The ceramic sealing ring 4 is transported to the pressure-bearing fixture plate 2 by means of vibration transport, and the pressure plate 1 applies downward pressure to flatten the ceramic sealing ring 4 on the pressure-bearing fixture plate 2 on the pressure-bearing fixture plate 2 At the same time, the expansion fixed pillar 5 vertically fixed on the fixed plate 3 passes through the through hole on the pressure-bearing fixture plate 2 and is inserted into the inner hole of the ceramic seal ring 4, and the front faces of each ceramic seal ring 4 are at the same level;

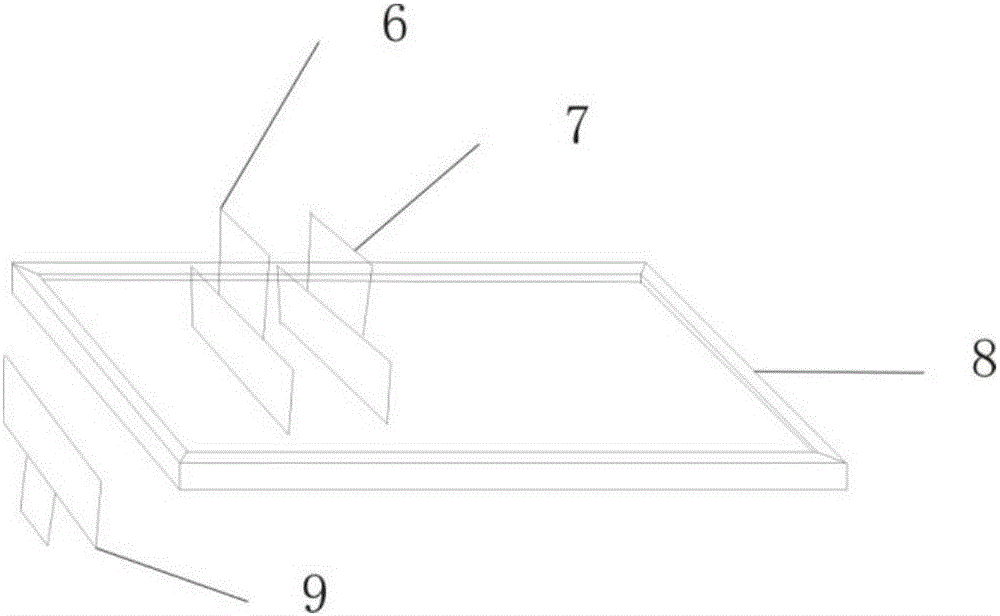

[0028] Step (2): The pressure-bearing fixture plate 2 and the positioning and fixing plate 3 with the ceramic sealing ring 4 installed in the step (1) are transported to the screen printing panel th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com