A pull-off socket clamping device

A clamping device and socket technology, which is used in launching devices, transportation and packaging, aircraft parts, etc., can solve the problems of control wire breaking and short circuit, low reliability, insufficient clamping force, etc., to reduce the degree of corrosion, Safe and reliable connection, easy maintenance and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

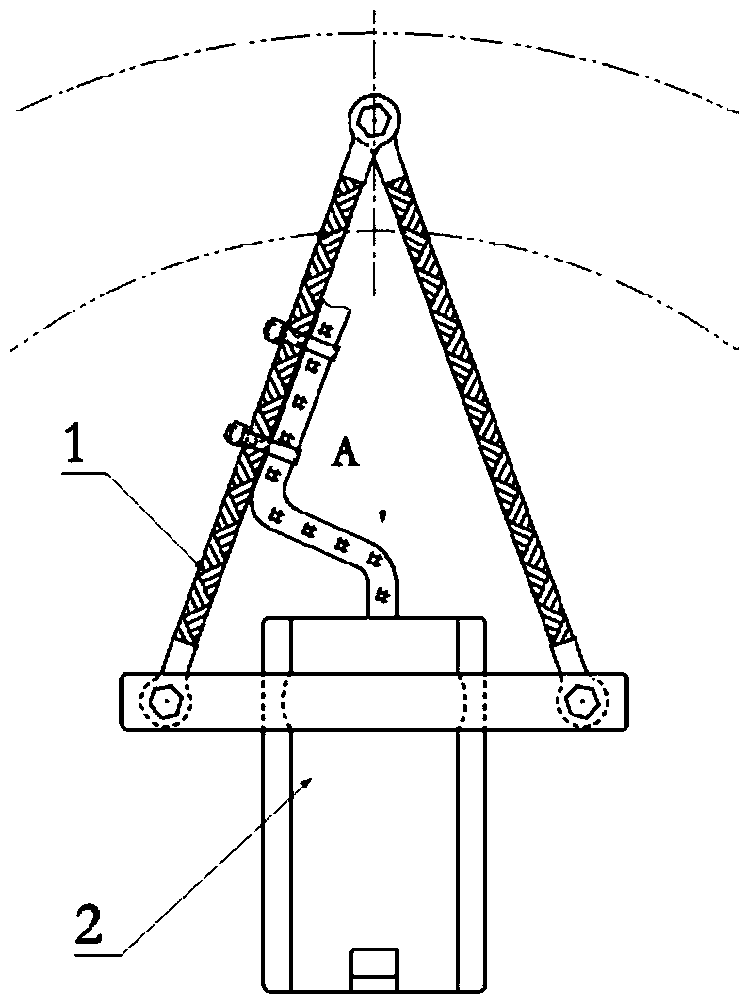

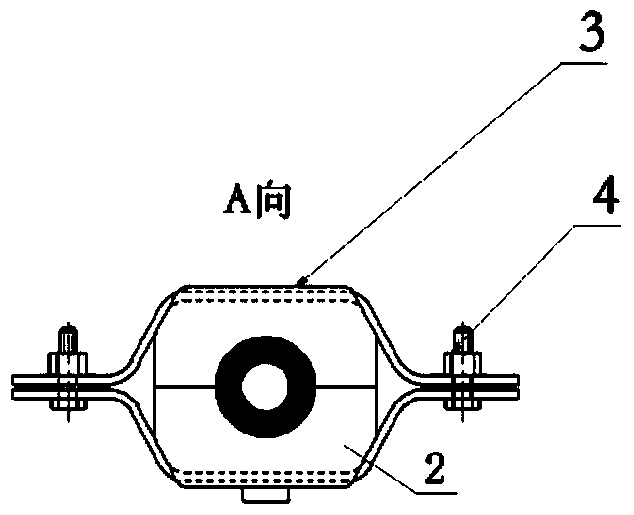

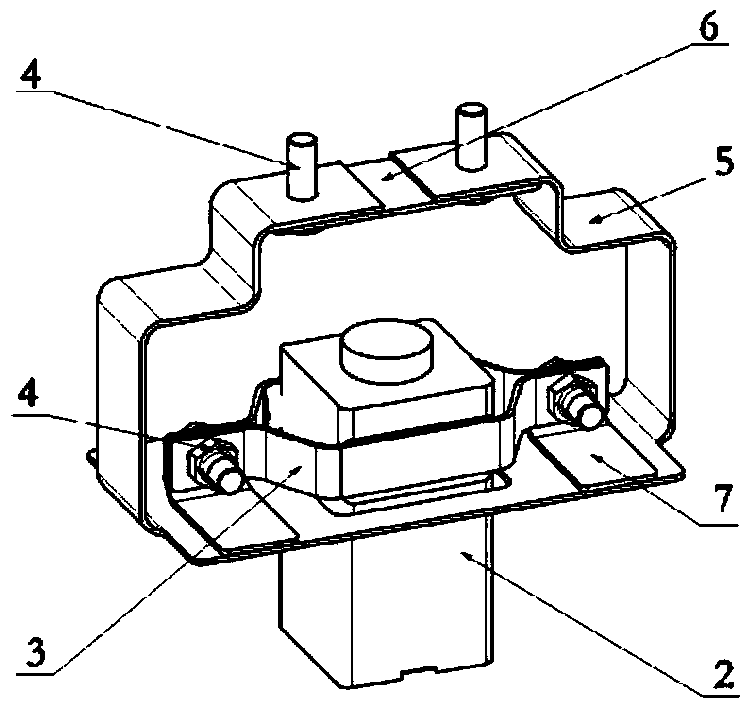

[0014] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

[0015] The device includes a pull-off socket 2, a clamping piece 3 and a several-shaped bracket 5, the pull-off socket 2 is clamped between two clamping pieces 3, and the two ends of the clamping piece 3 pass through the L-shaped angle piece 7 are respectively fixed on one end of two a few font supports 5. In order to improve the reliability that the whole is fixed on the body, a reinforcement plate 6 is provided at the fixed end of the several-shaped support 5 and the body, and the several-shaped support 5 is fixed on the body by the reinforced plate 6 and the connecting bolt 4.

[0016] In order to improve the fixing reliability of the pull-off socket 2, an arc-shaped groove 9 is provided at the contact position between the pull-off socket 2 and the clamping piece 3, and an anti-slip rubber member 8 is fixed at the position where the clamping piece 3 conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com