Plastic wrap packaging machine

A technology of cling film and packaging machine, which is used in transportation and packaging, sending objects, processing of thin materials, etc. It can solve the problems of high cost of automatic machinery, complex structure, and uneven cutting, and achieve easy maintenance and cleaning. Simple and effective in solving health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

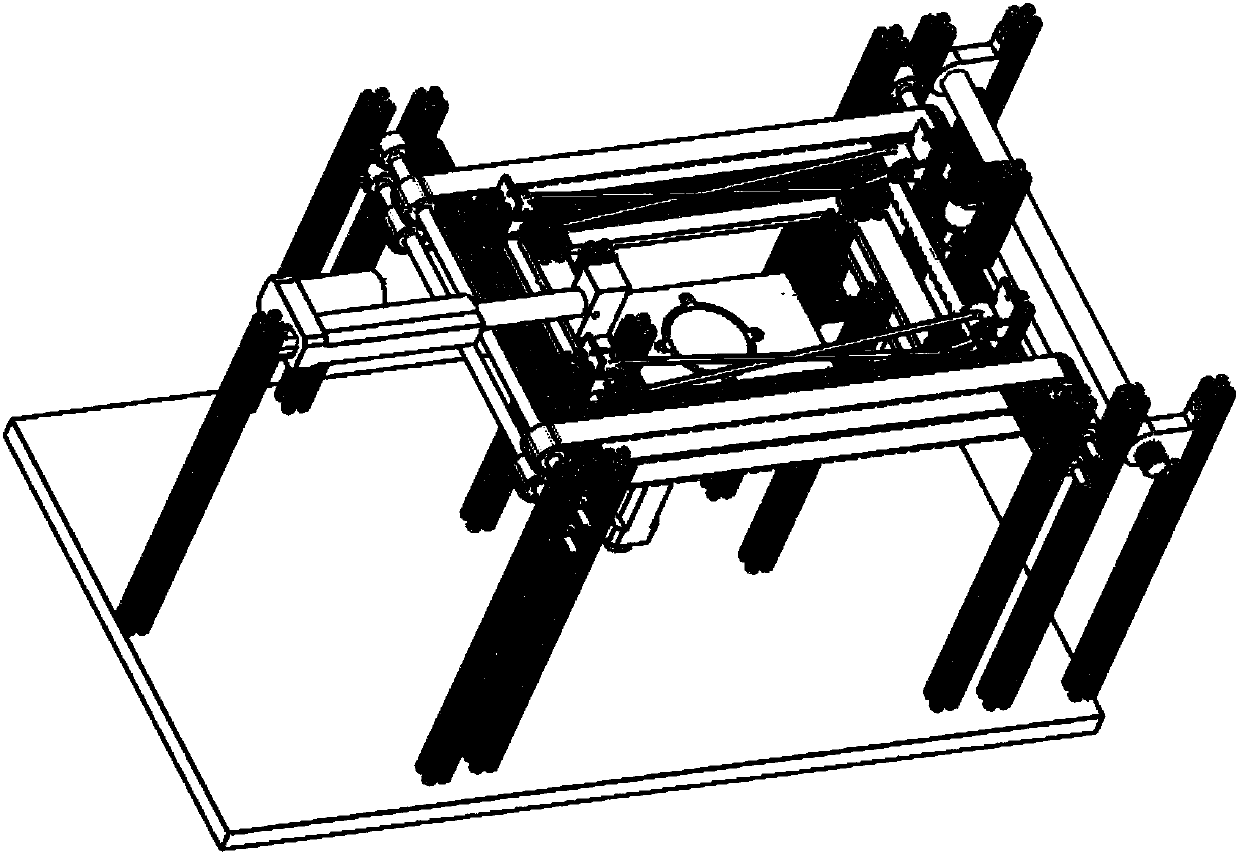

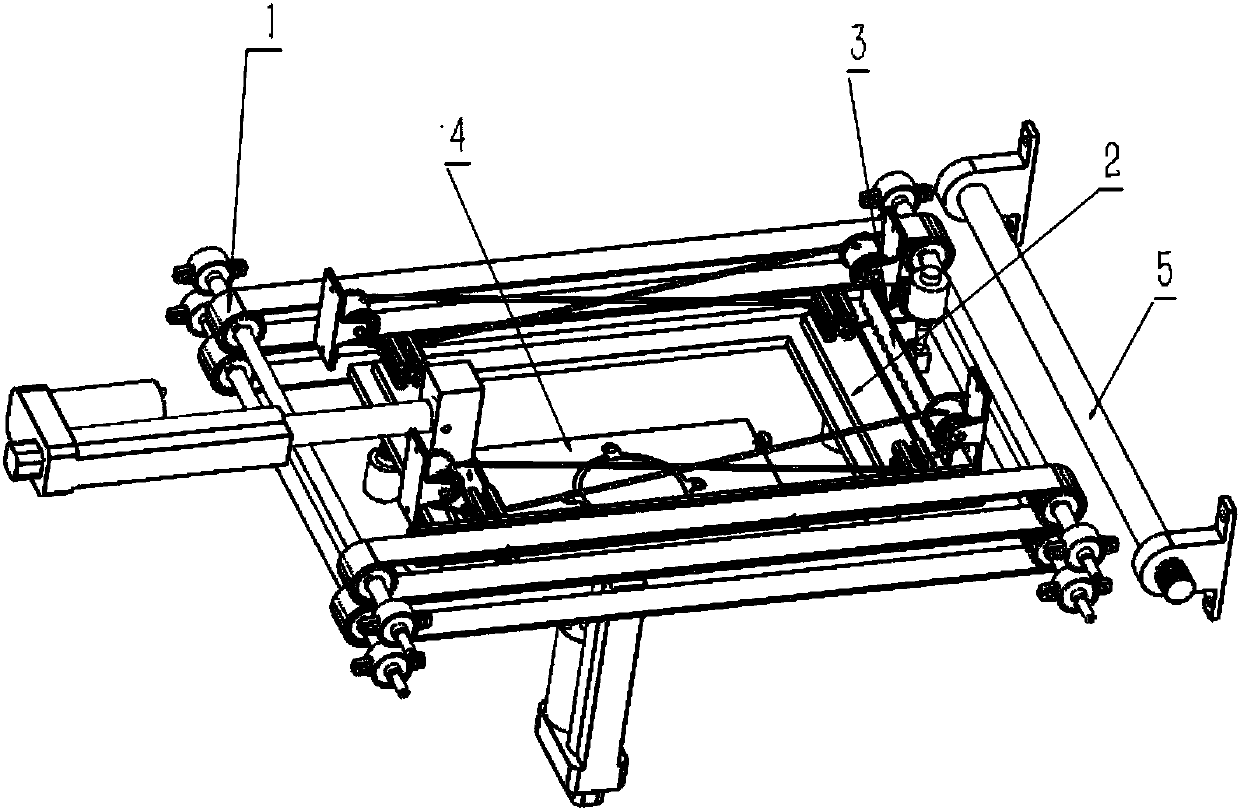

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

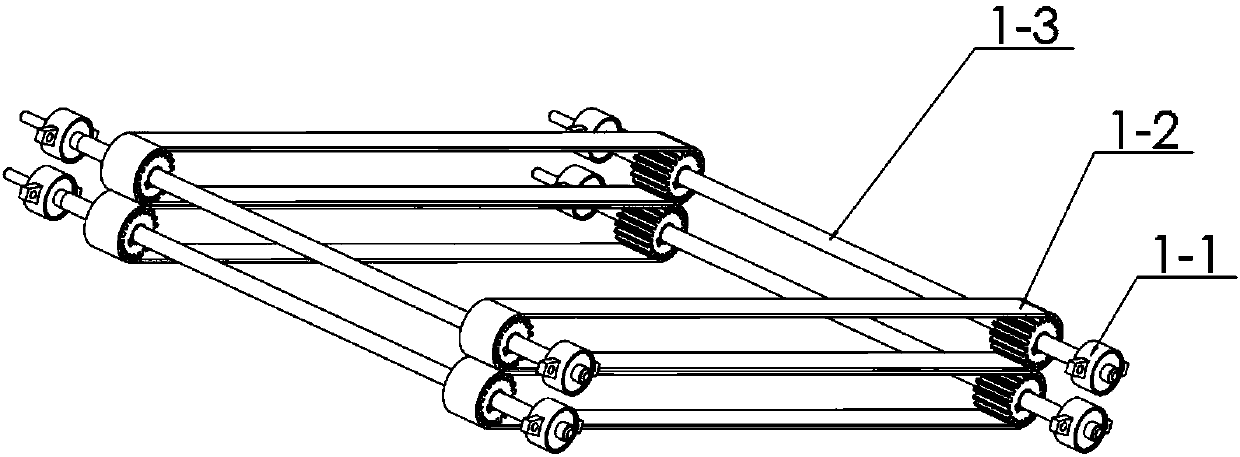

[0023] Such as Picture 1-1 and 1-2 As shown, the plastic wrap packaging machine includes a plastic wrap loop pulling device 1, a plastic wrap clamping device 2, a plastic wrap cutting device 3, a tray lifting device 4, a plastic wrap optical axis 5, a frame and a controller. The controller controls the action of the fresh-keeping film circular pulling device 1, the fresh-keeping film cutting device 2, the fresh-keeping film clamping device 3 and the tray lifting device 4; Pull out; the pulled out plastic wrap is clamped by the plastic wrap clamping device 2 and then cut off by the plastic wrap cutting device 3; the tray lifting device 4 transports the tray up and at the same time the plastic wrap clamping device 2 wraps both sides of the cut plastic wrap For the tray, manually take out the tray while making the other two sides of the plastic wrap wrap the tray.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com