Patents

Literature

76results about How to "Small and lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

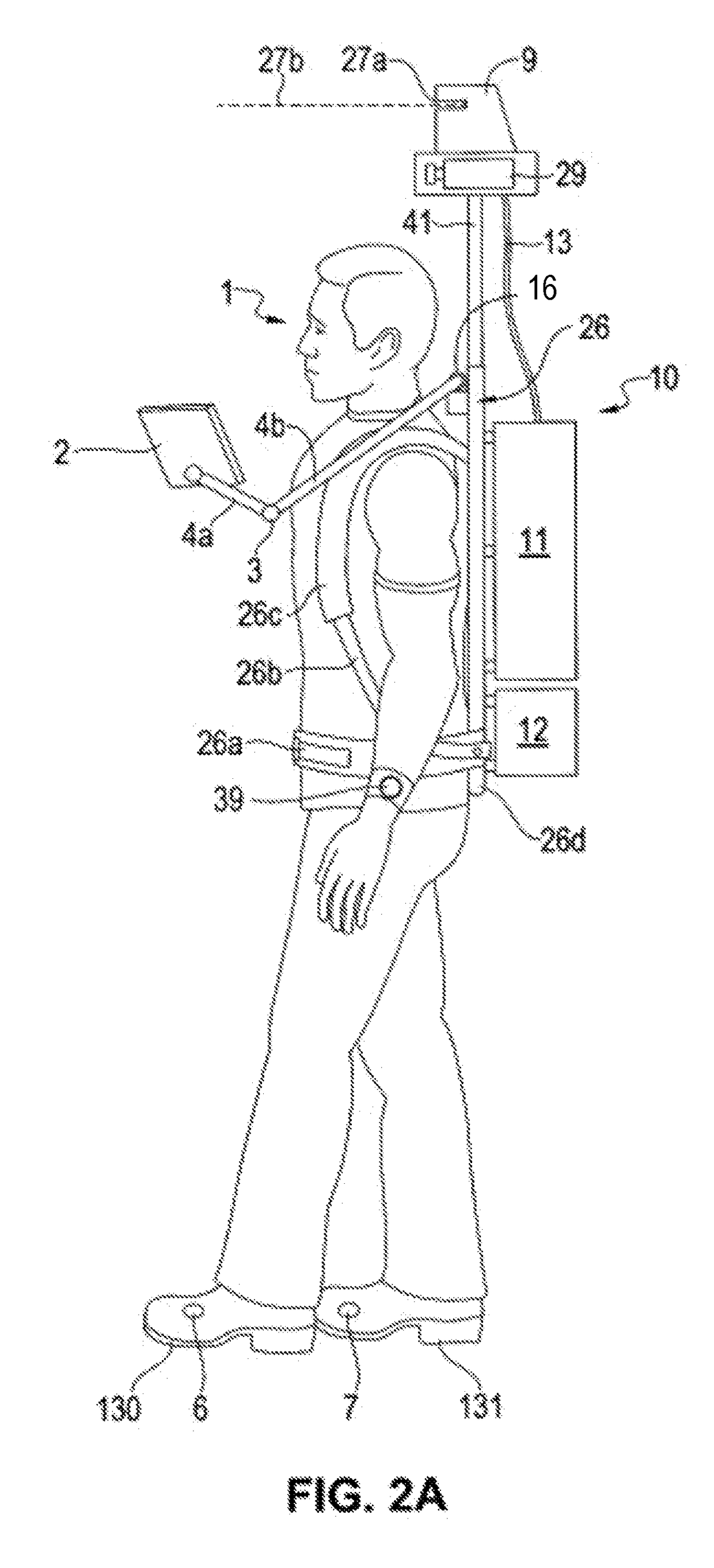

Portable Peritoneal Dialysis System

ActiveUS20100114012A1Comfortable to wearComfortable to carryMedical devicesDialysisSimple Organic CompoundsMetabolite

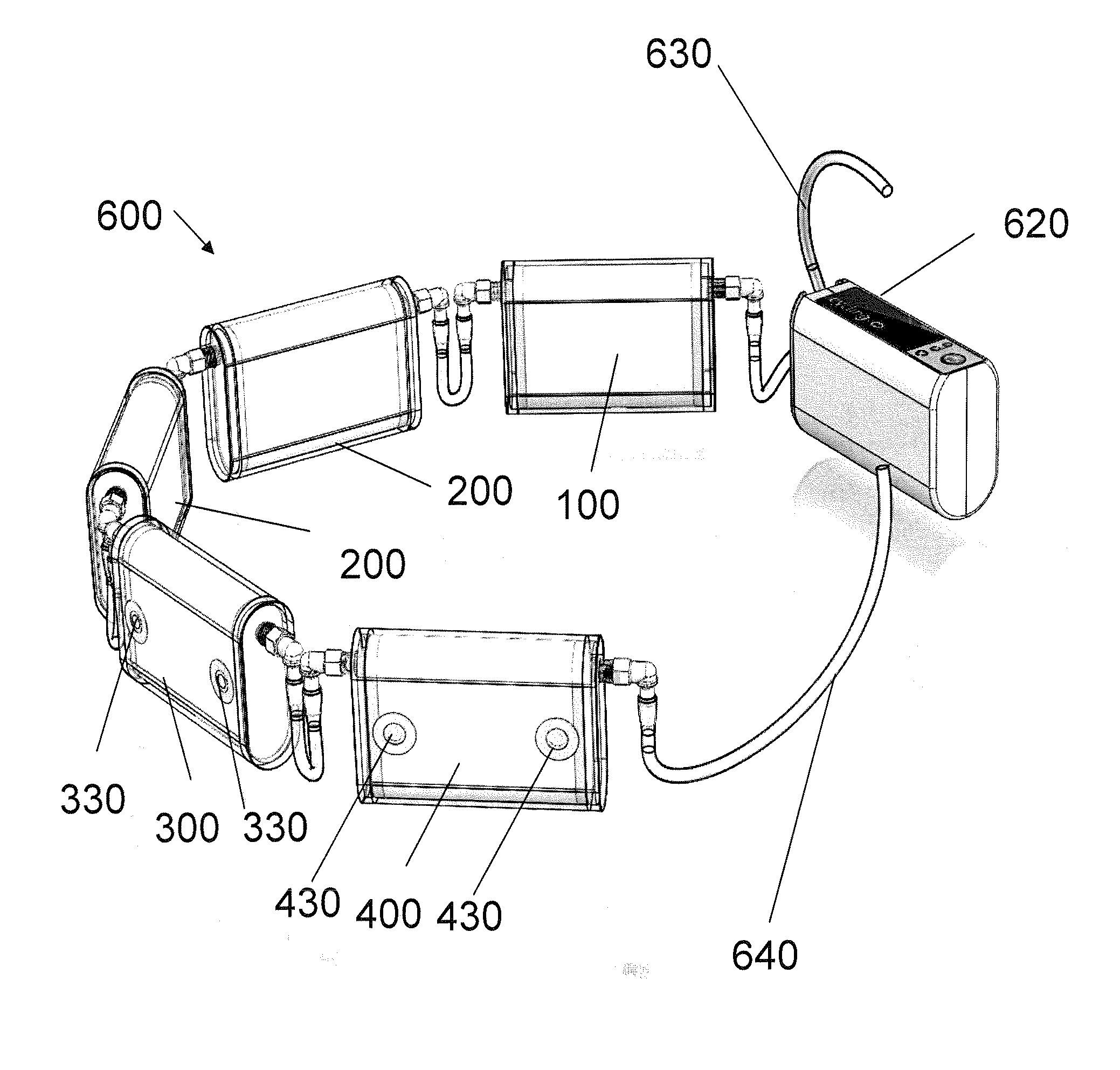

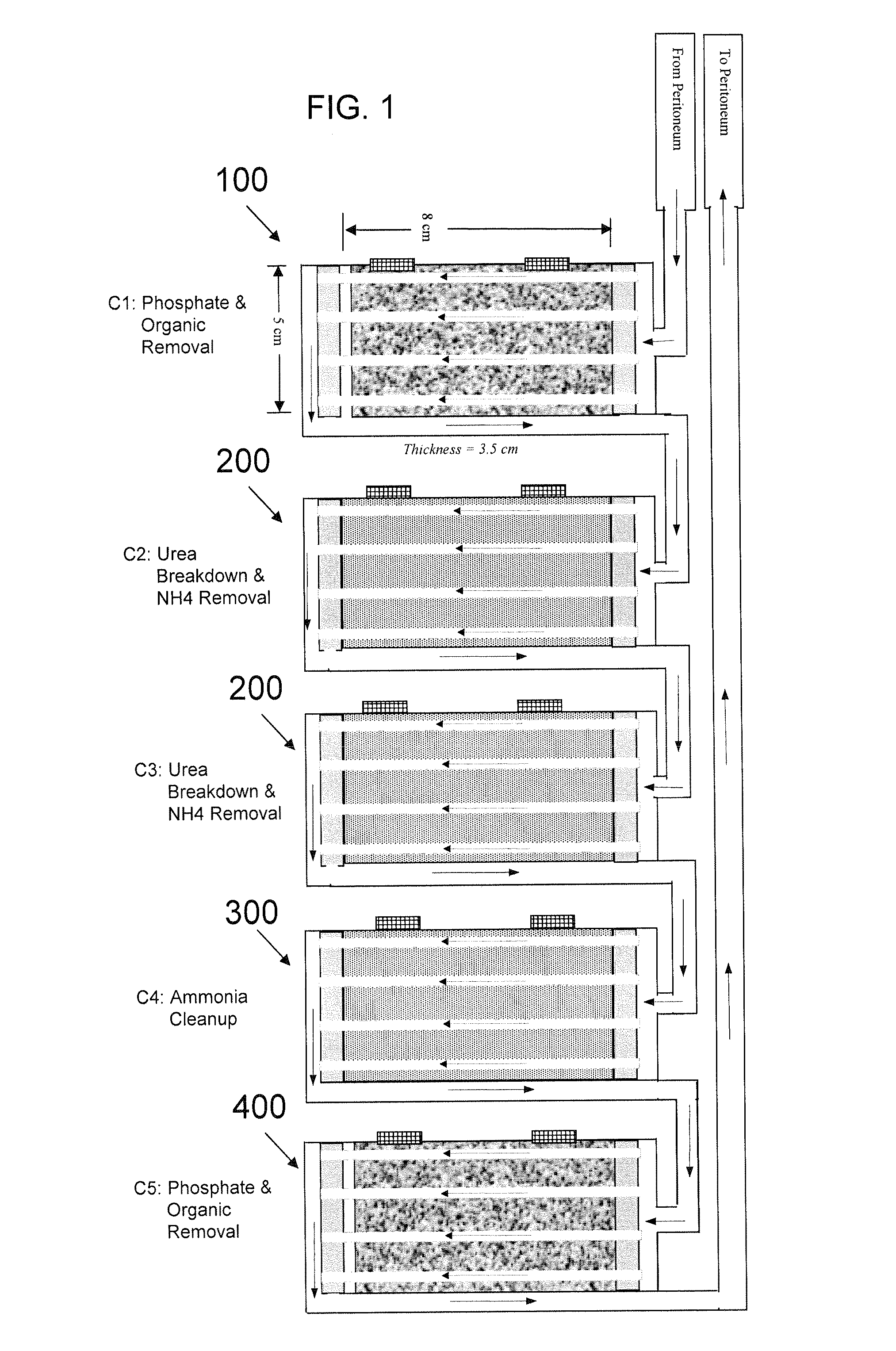

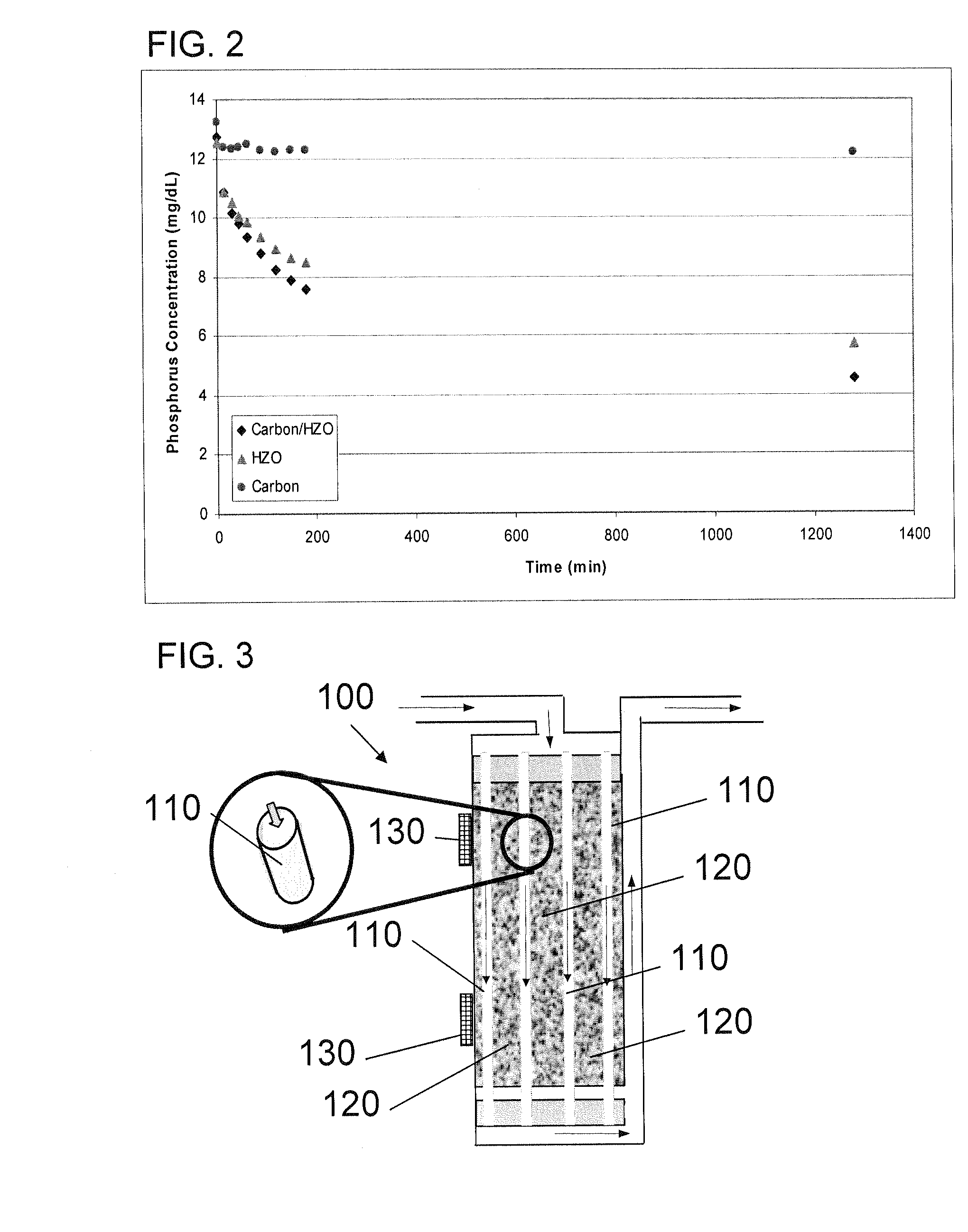

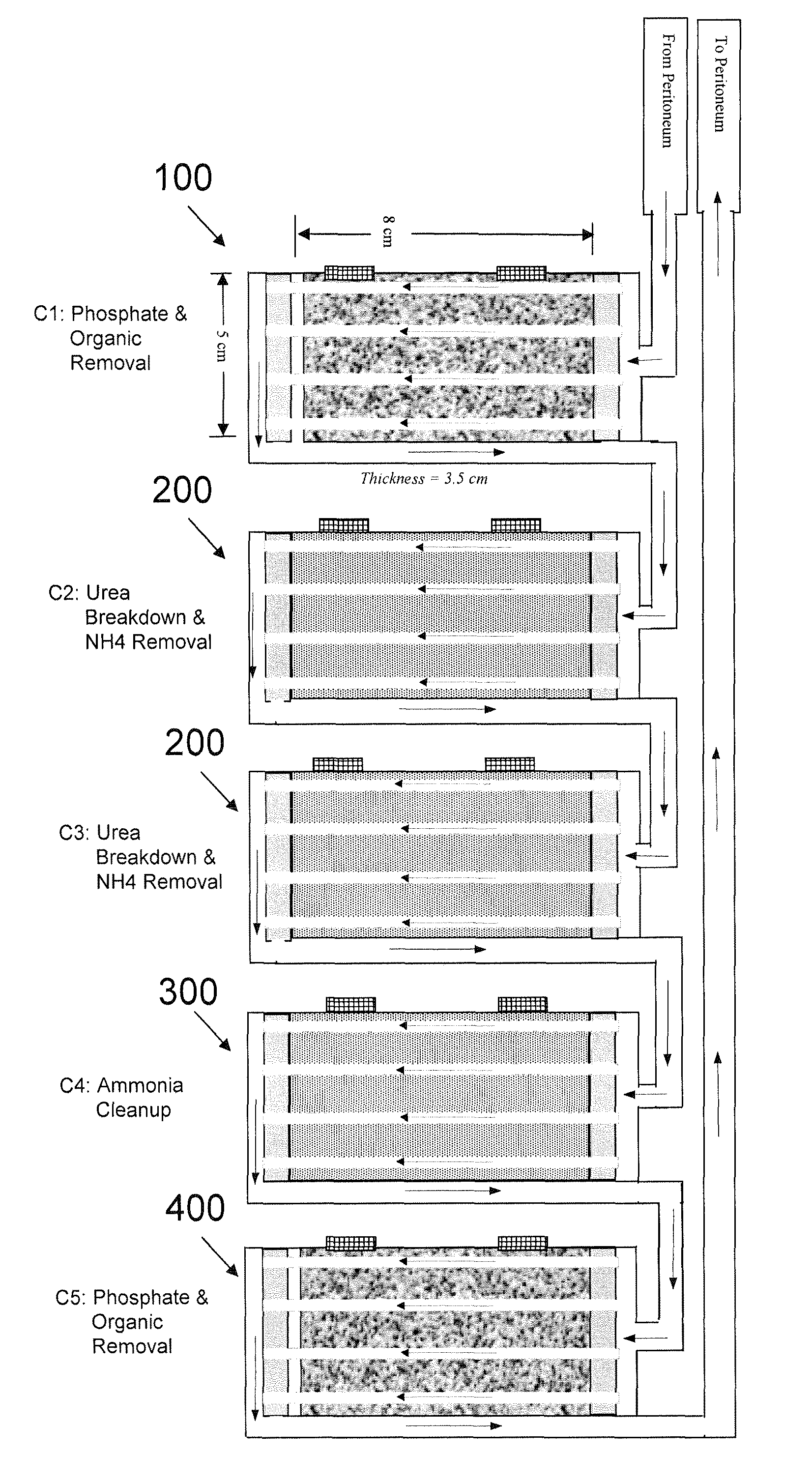

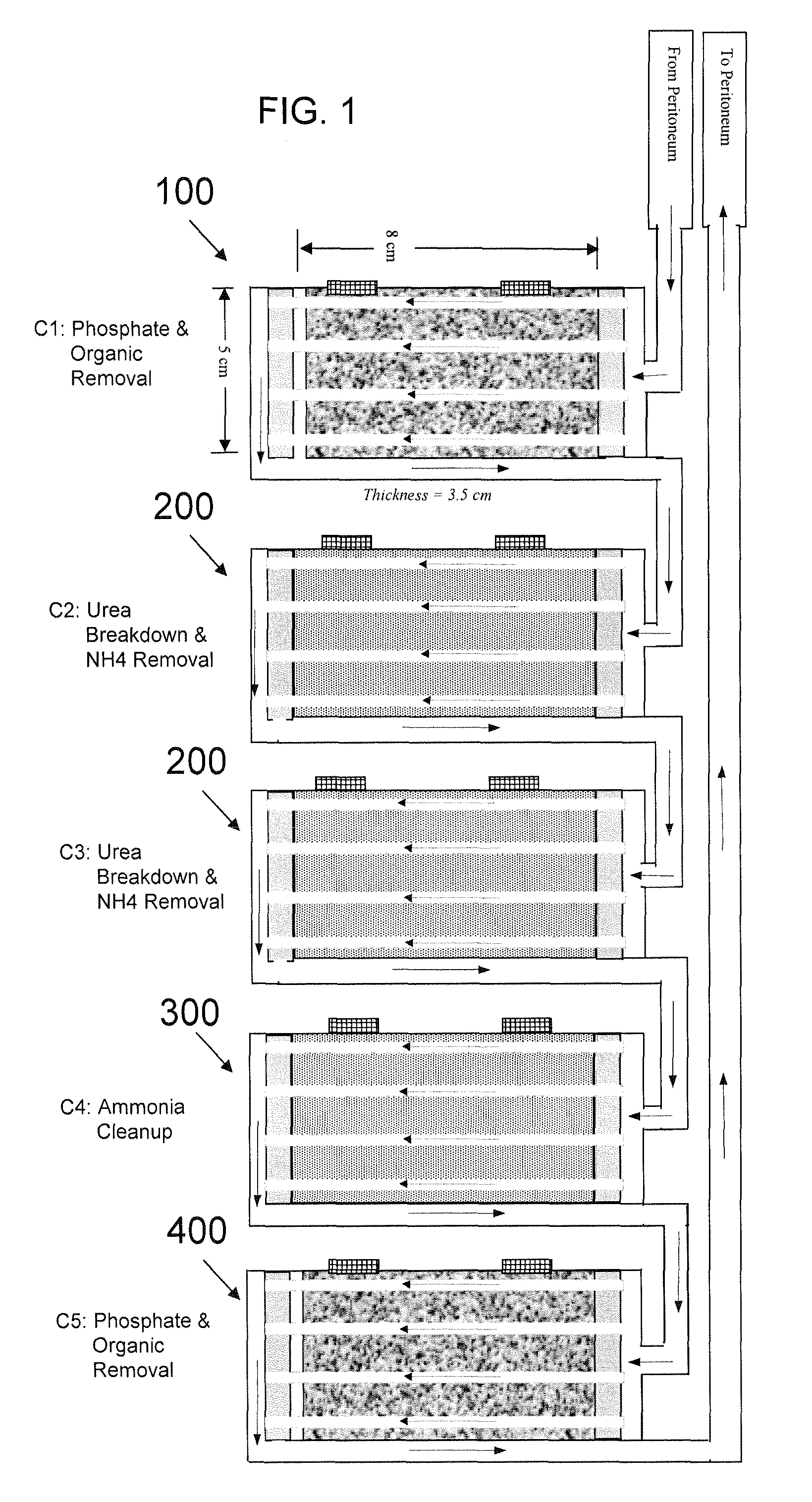

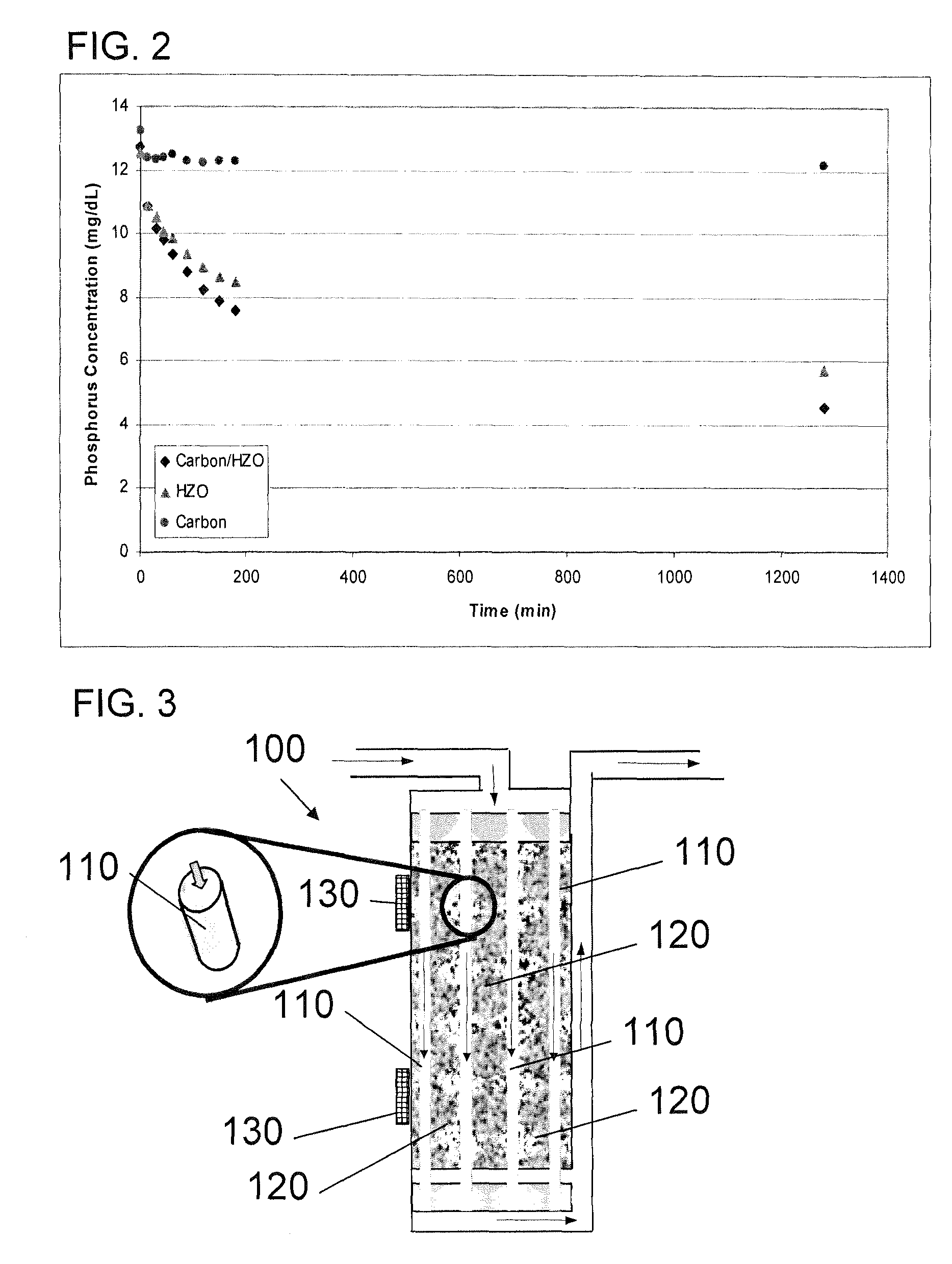

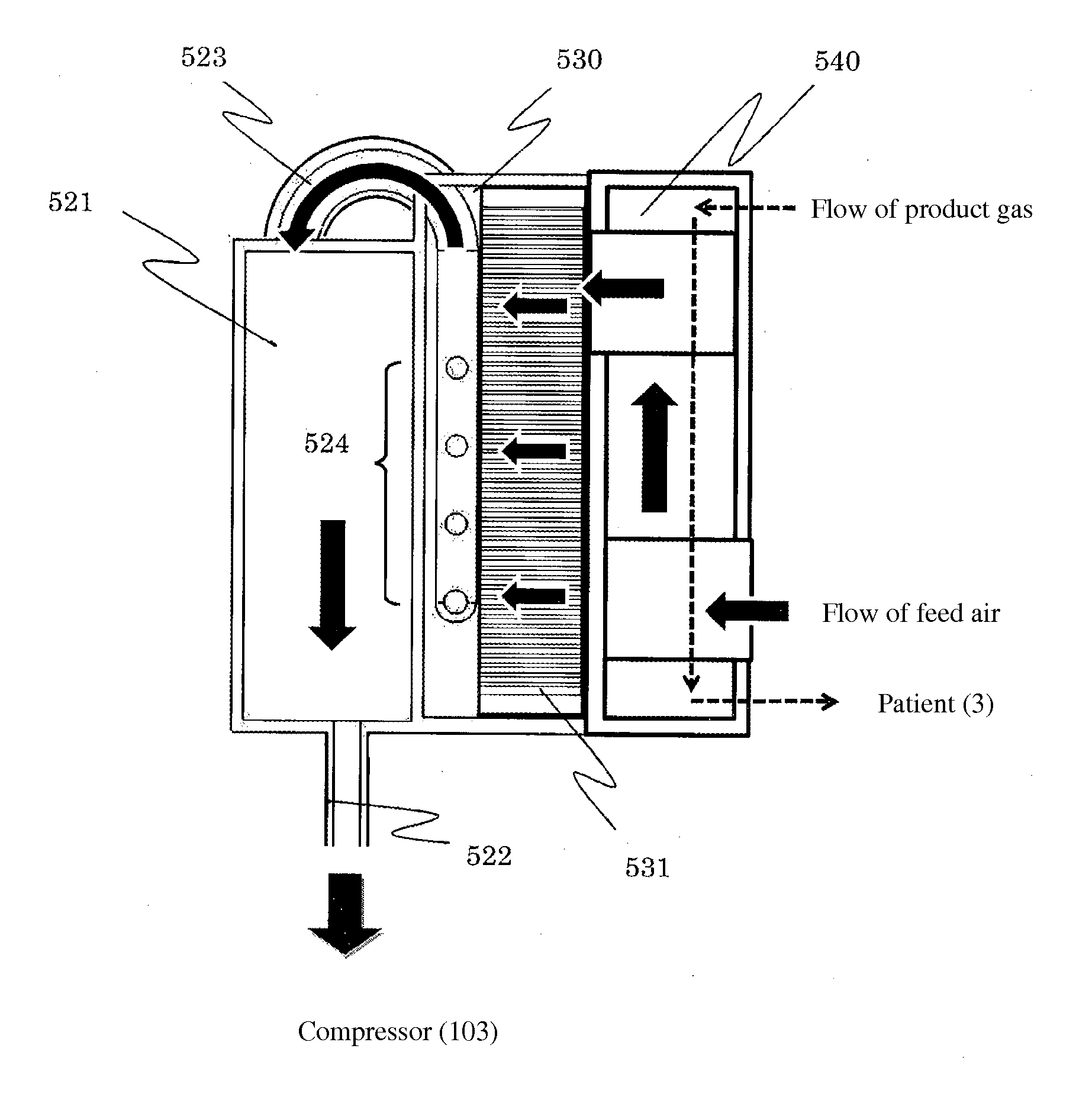

A portable peritoneal dialysis system for a patient includes an inlet port for providing inflow to the patient's peritoneal cavity, an outlet port for providing outflow from the patient's peritoneal cavity, and a volume of dialysate for flow into and out of the patient's peritoneal cavity, thereby removing from the dialysate uremic waste metabolites that have diffused into the dialysate. The portable peritoneal dialysis system also includes a closed liquid flow loop, including a pump, for flowing the dialysate into and out of the patient's peritoneal cavity, and an organic- and phosphate-removing stage, including at least one replaceable cartridge in the closed liquid flow loop, the cartridge containing material for removing organic compounds and phosphate from dialysate removed from the patient's peritoneal cavity. The portable peritoneal dialysis system further includes a urea- and ammonia-removing stage, including at least one replaceable cartridge in the closed liquid flow loop, the cartridge containing material for removing urea and ammonia from dialysate removed from the patient's peritoneal cavity, the material being packed around semi-permeable hollow fibers with interior fiber walls that reject cations, thereby retaining cations in the dialysate.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Portable peritoneal dialysis system

ActiveUS8777892B2Comfortably wornComfortable to carrySolvent extractionMedical devicesHollow fibreFiber

A portable peritoneal dialysis system for a patient includes an inlet port for providing inflow to the patient's peritoneal cavity, an outlet port for providing outflow from the patient's peritoneal cavity, and a volume of dialysate for flow into and out of the patient's peritoneal cavity, thereby removing from the dialysate uremic waste metabolites that have diffused into the dialysate. The portable peritoneal dialysis system also includes a closed liquid flow loop, including a pump, for flowing the dialysate into and out of the patient's peritoneal cavity, and an organic- and phosphate-removing stage, including at least one replaceable cartridge in the closed liquid flow loop, the cartridge containing material for removing organic compounds and phosphate from dialysate removed from the patient's peritoneal cavity. The portable peritoneal dialysis system further includes a urea- and ammonia-removing stage, including at least one replaceable cartridge in the closed liquid flow loop, the cartridge containing material for removing urea and ammonia from dialysate removed from the patient's peritoneal cavity, the material being packed around semi-permeable hollow fibers with interior fiber walls that reject cations, thereby retaining cations in the dialysate.

Owner:FRESENIUS MEDICAL CARE HLDG INC

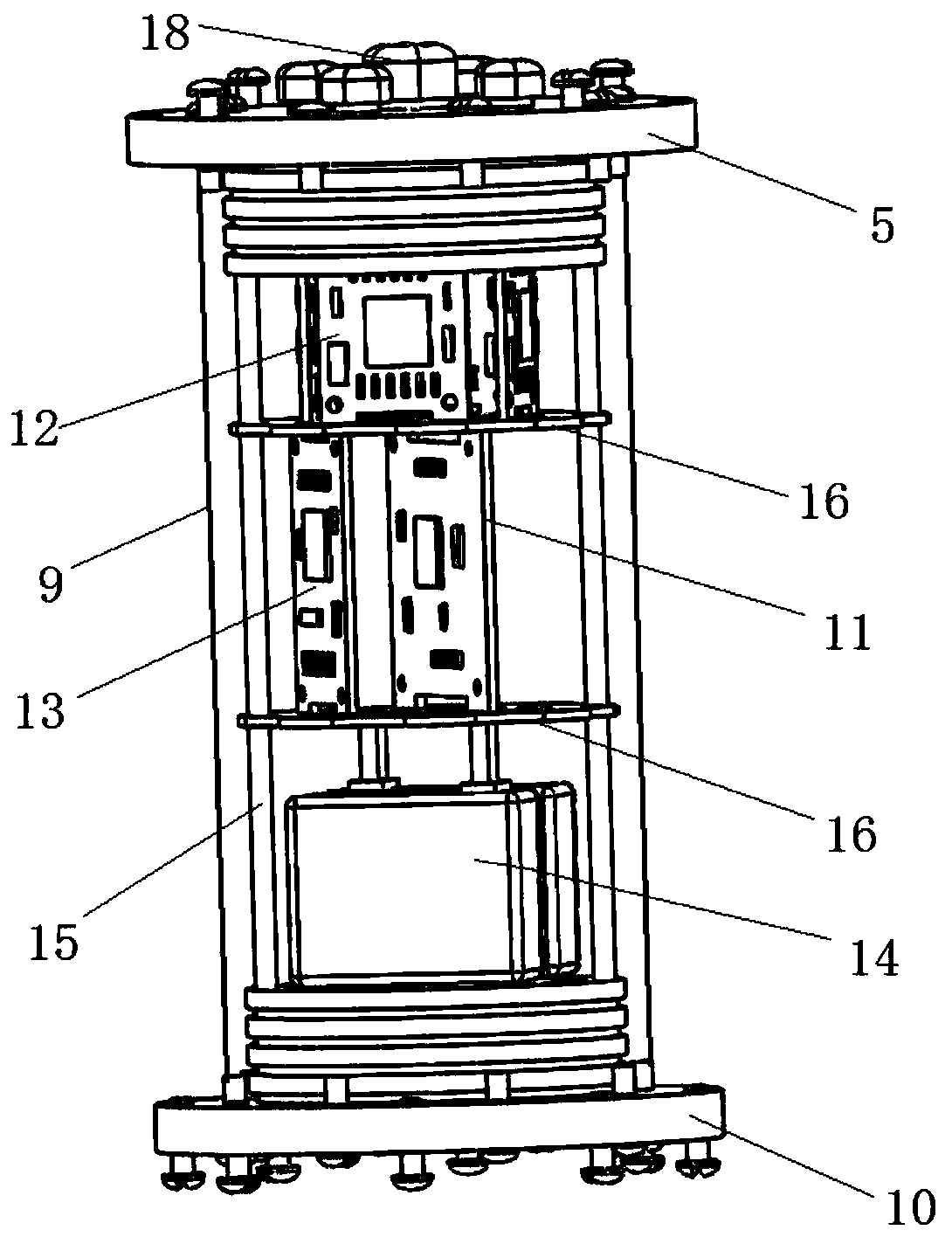

Apparatus, Systems and Methods for Point Cloud Generation and Constantly Tracking Position

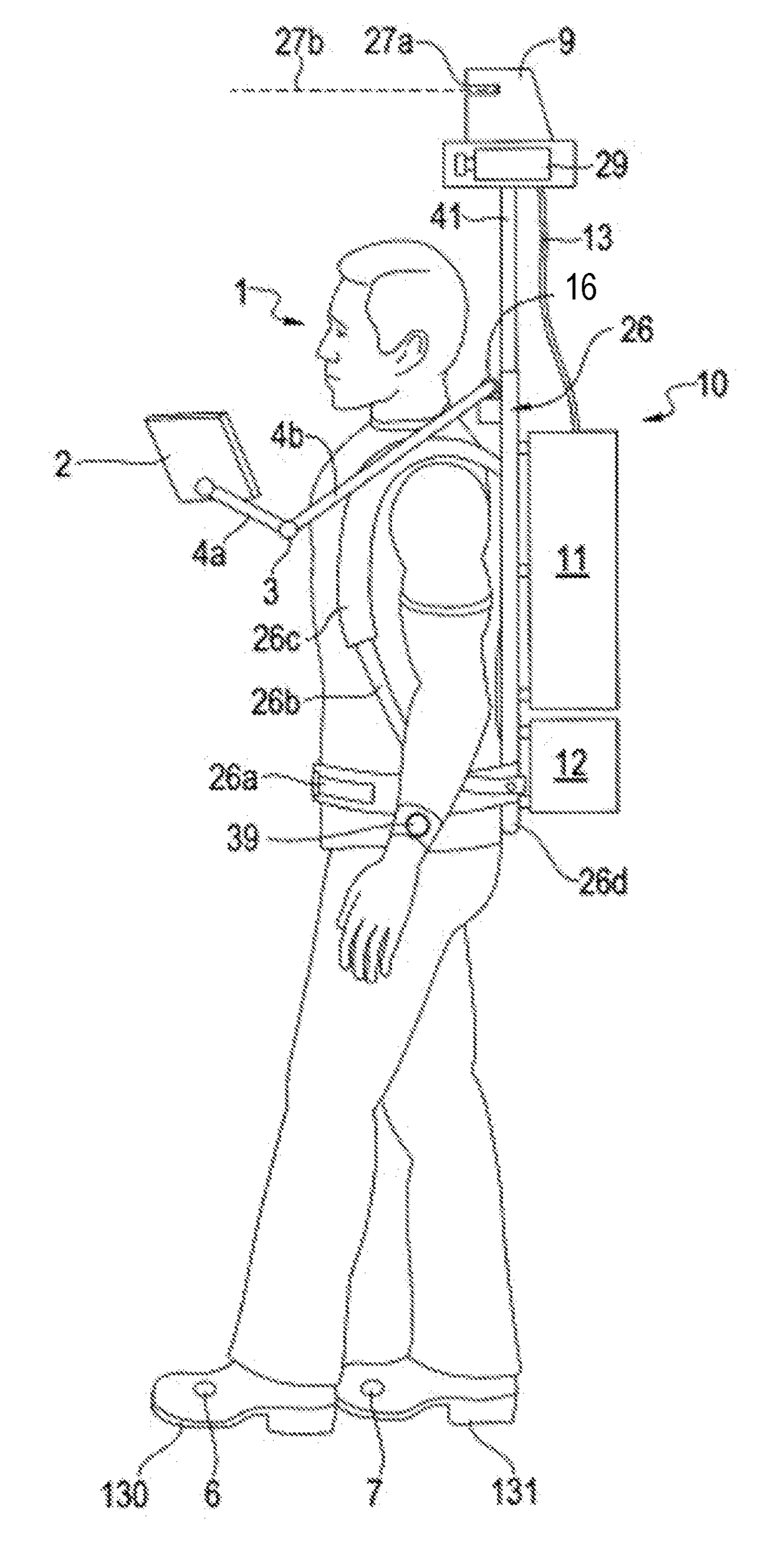

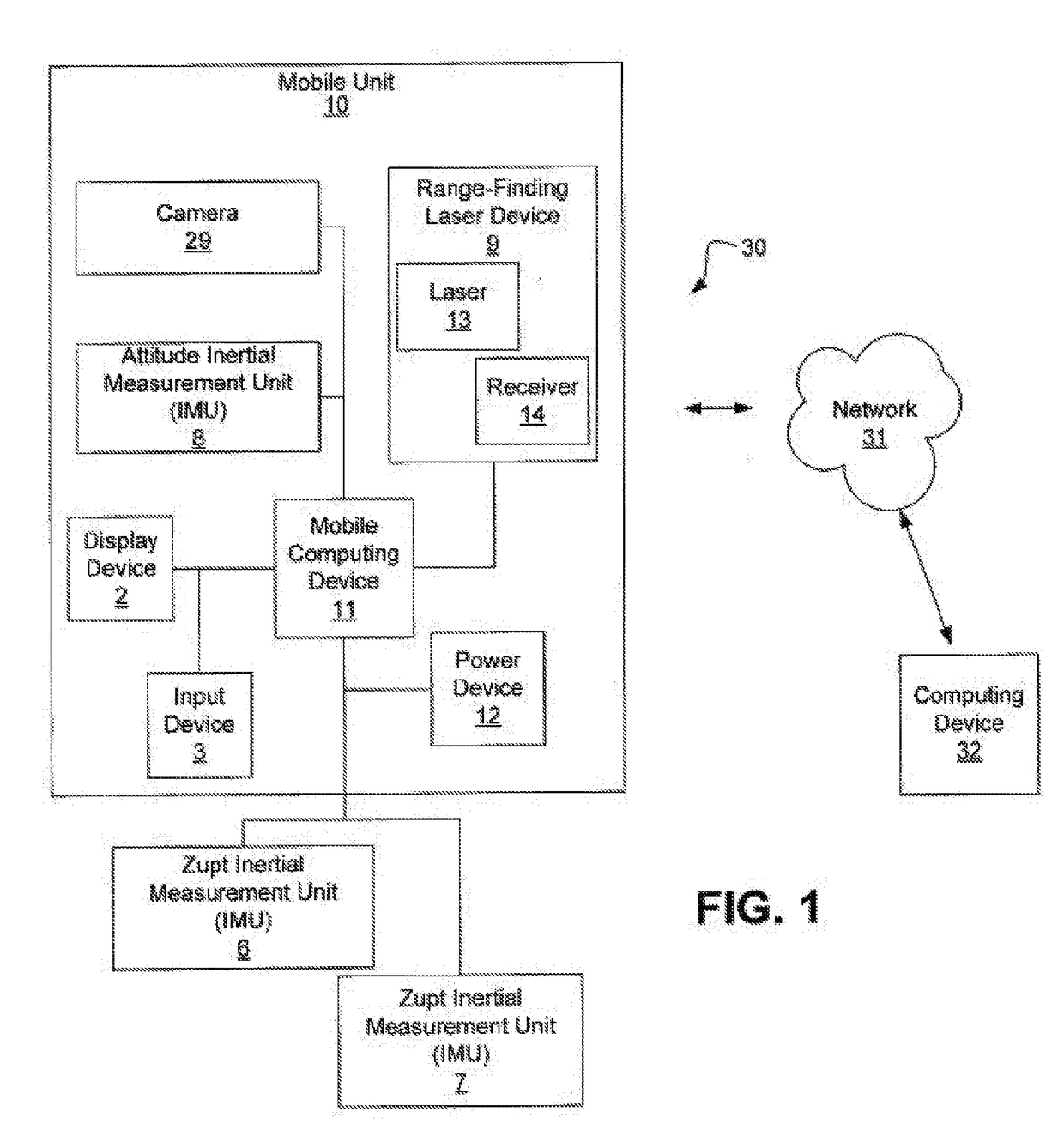

ActiveUS20170123066A1Move fastShort timeOptical rangefindersActive open surveying meansInertial measurement unitData point

A system having a range-finding laser device (RFLD) is configured to be coupled to an operator performs scans producing range and angle data points on surrounding structures. An attitude inertial measuring unit (IMU) attached to the RFLD measures pitch and roll of the RFLD and at least one zero-velocity update (zupt) IMU coupled to the operator is used to estimate the position, velocity and yaw of the operator. The system has computer logic that transforms data points from sensor frames of reference to a global frame of reference and merges transformed data points in a point cloud that can be used to generate images of scanned environments on a display.

Owner:ROBOTIC PARADIGM SYST LLC

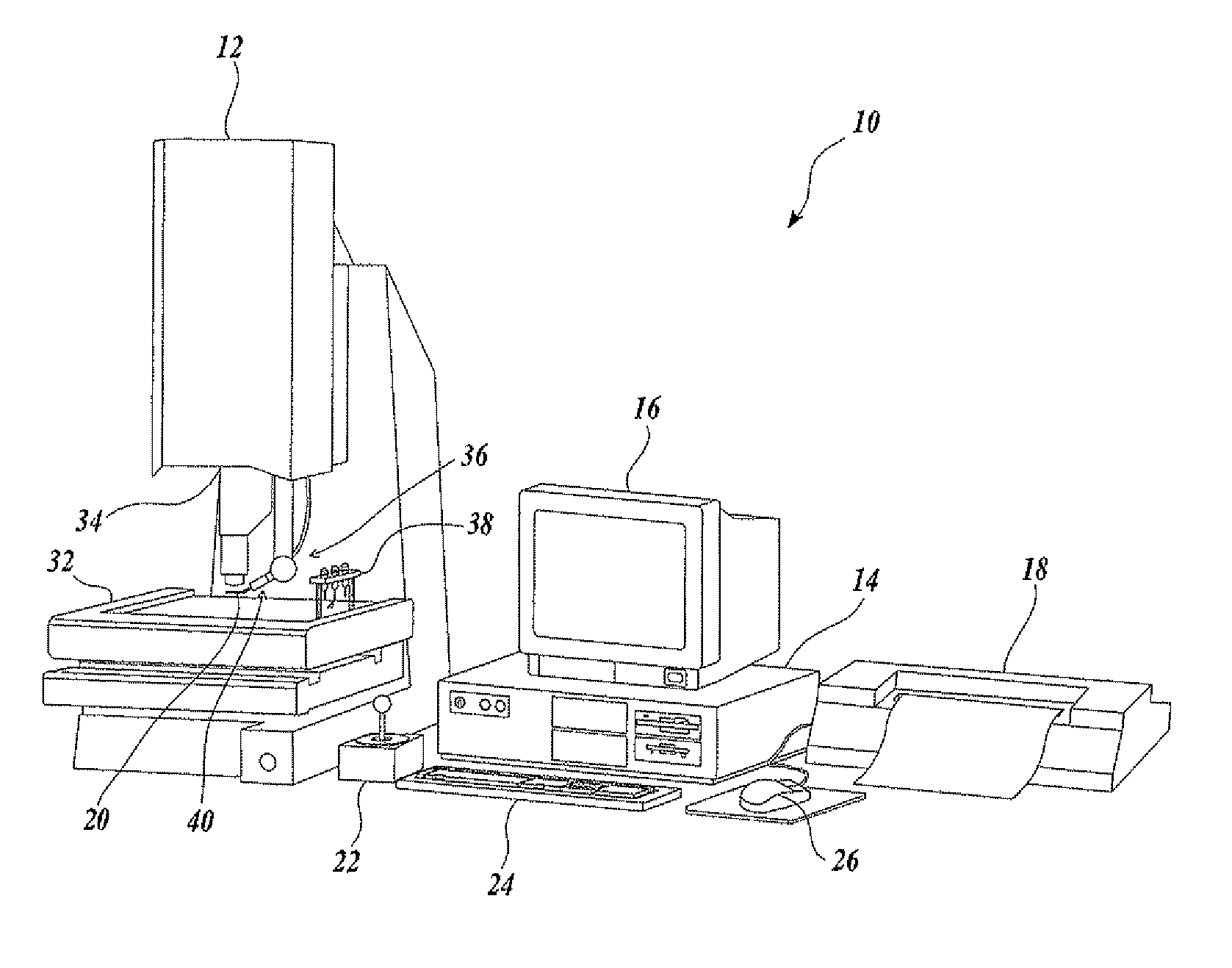

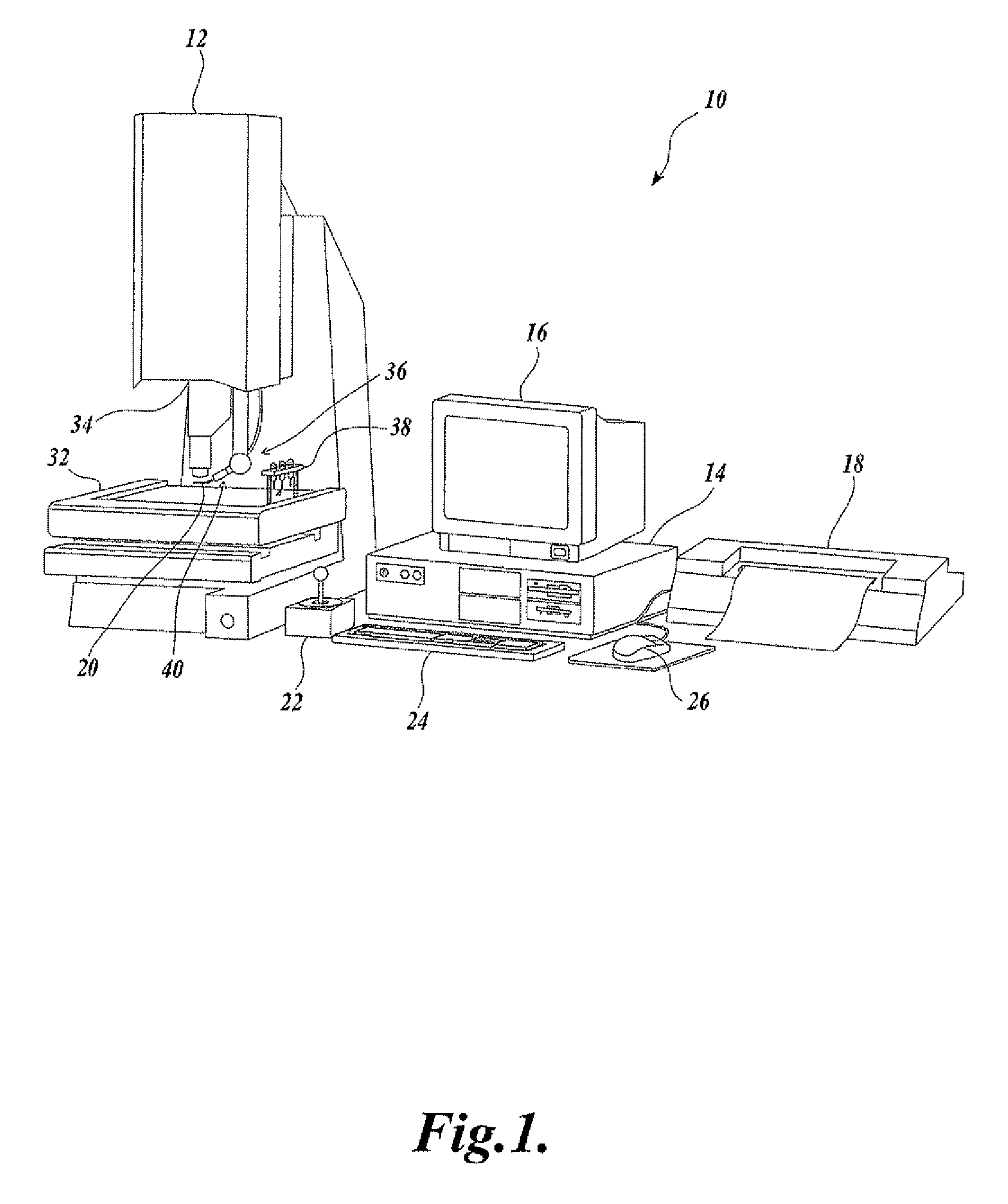

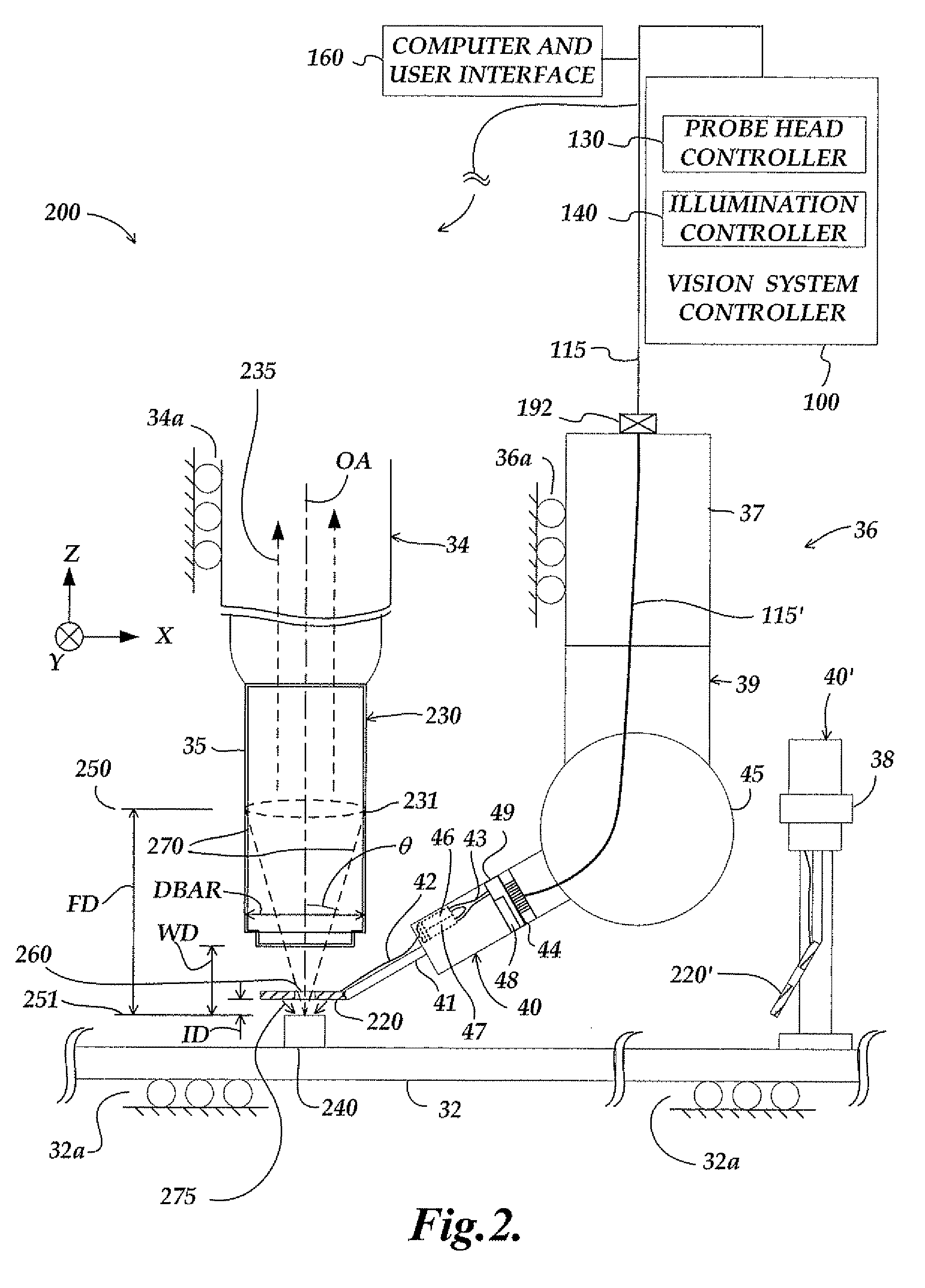

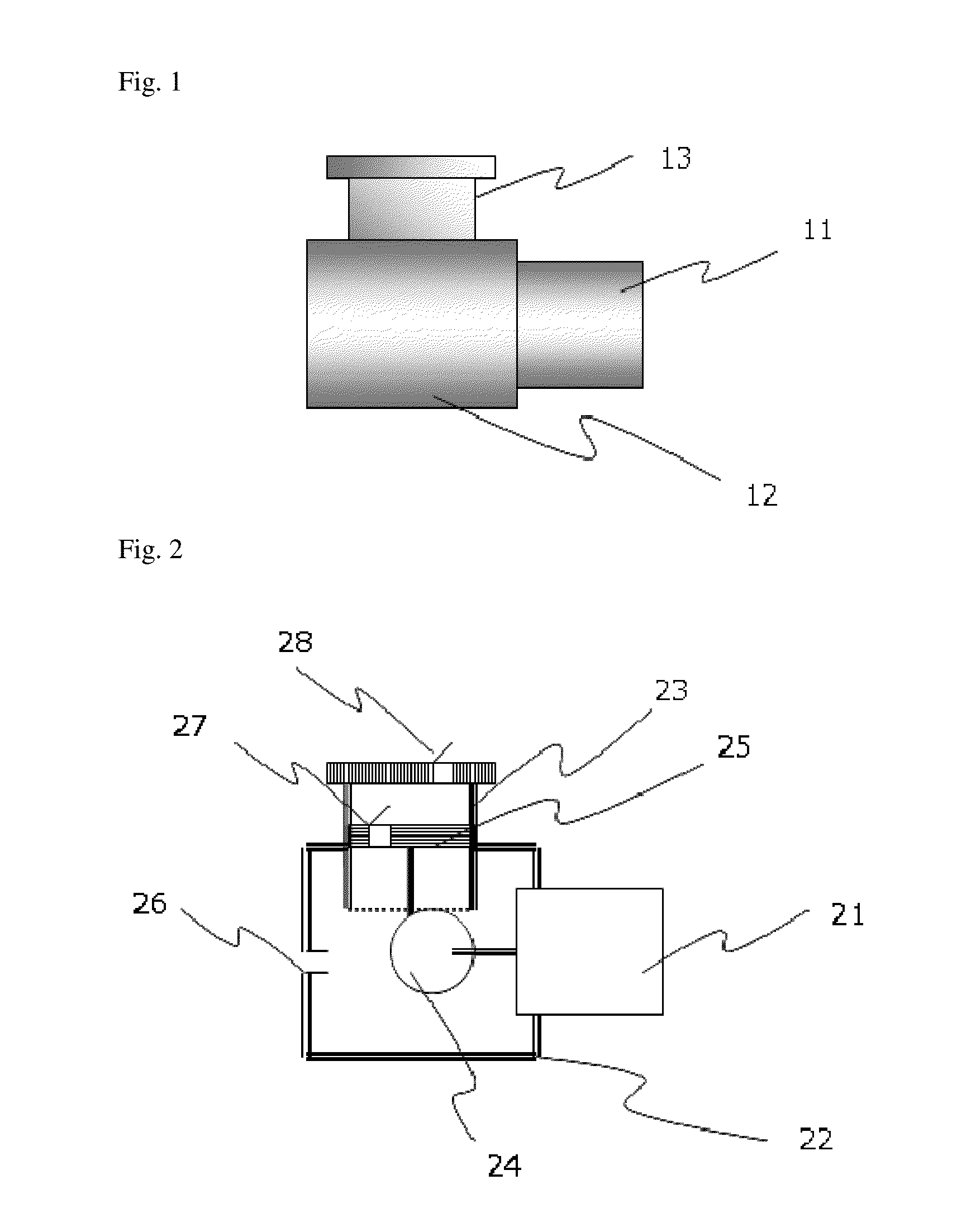

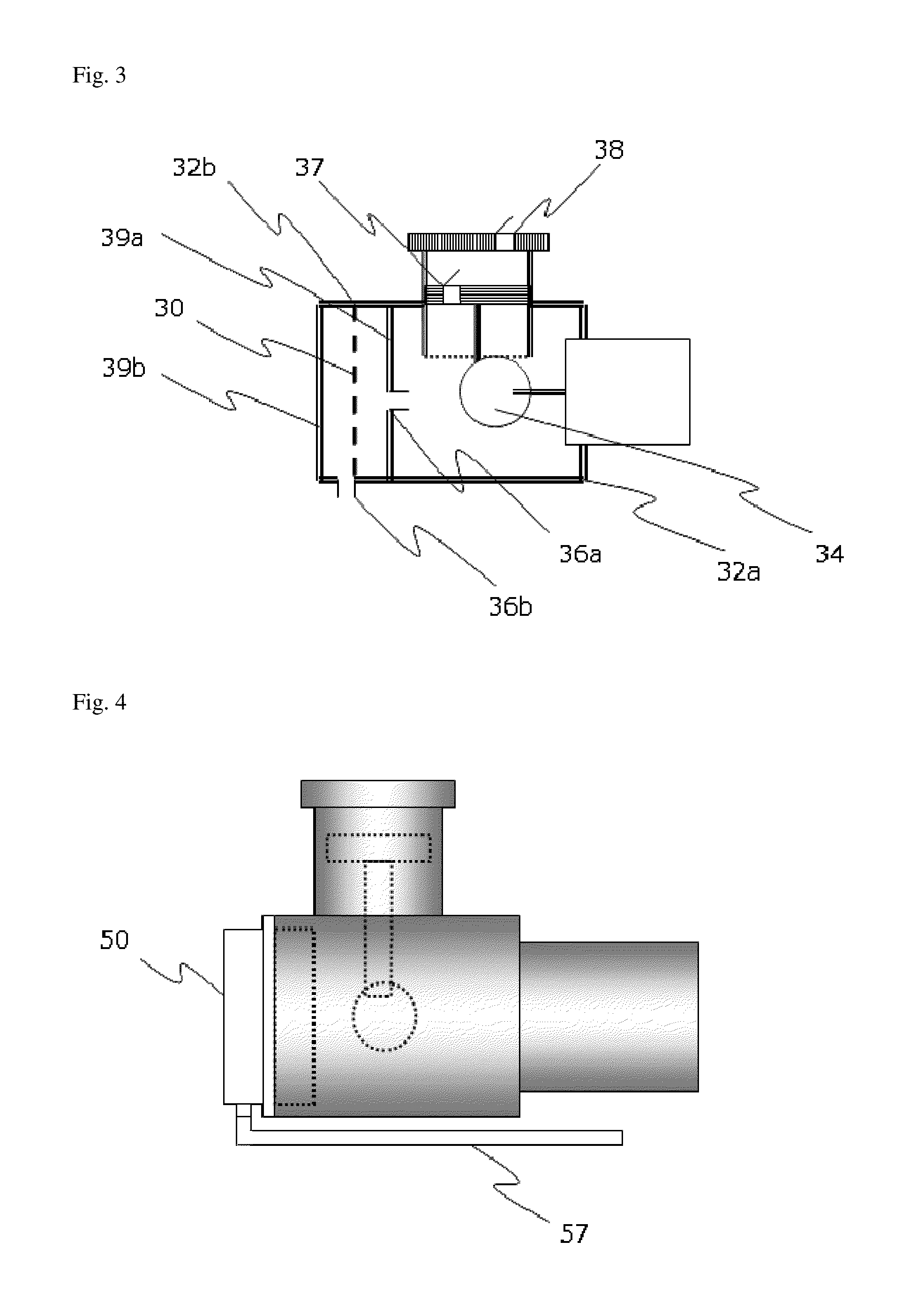

Controllable micro light assembly

ActiveUS8085295B2Increase speedChange positionTelevision system detailsWith electric batteriesMachine visionOptical axis

A micro light interface assembly for a microscopic machine vision inspection system includes a micro light assembly. The micro light assembly provides addressable light emitting elements arranged around the periphery of an aperture having an aperture dimension DAPMIN that is smaller than a barrel dimension DBAR of the inspection system objective lens. The aperture may be located along the optical axis and within the working distance of the objective lens such that the light emitting elements are closely arranged around a field of view. The micro light interface assembly may be held and operated through a connection element that may be used for the interchanging the micro light interface assembly with a touch probe, in some embodiments.

Owner:MITUTOYO CORP

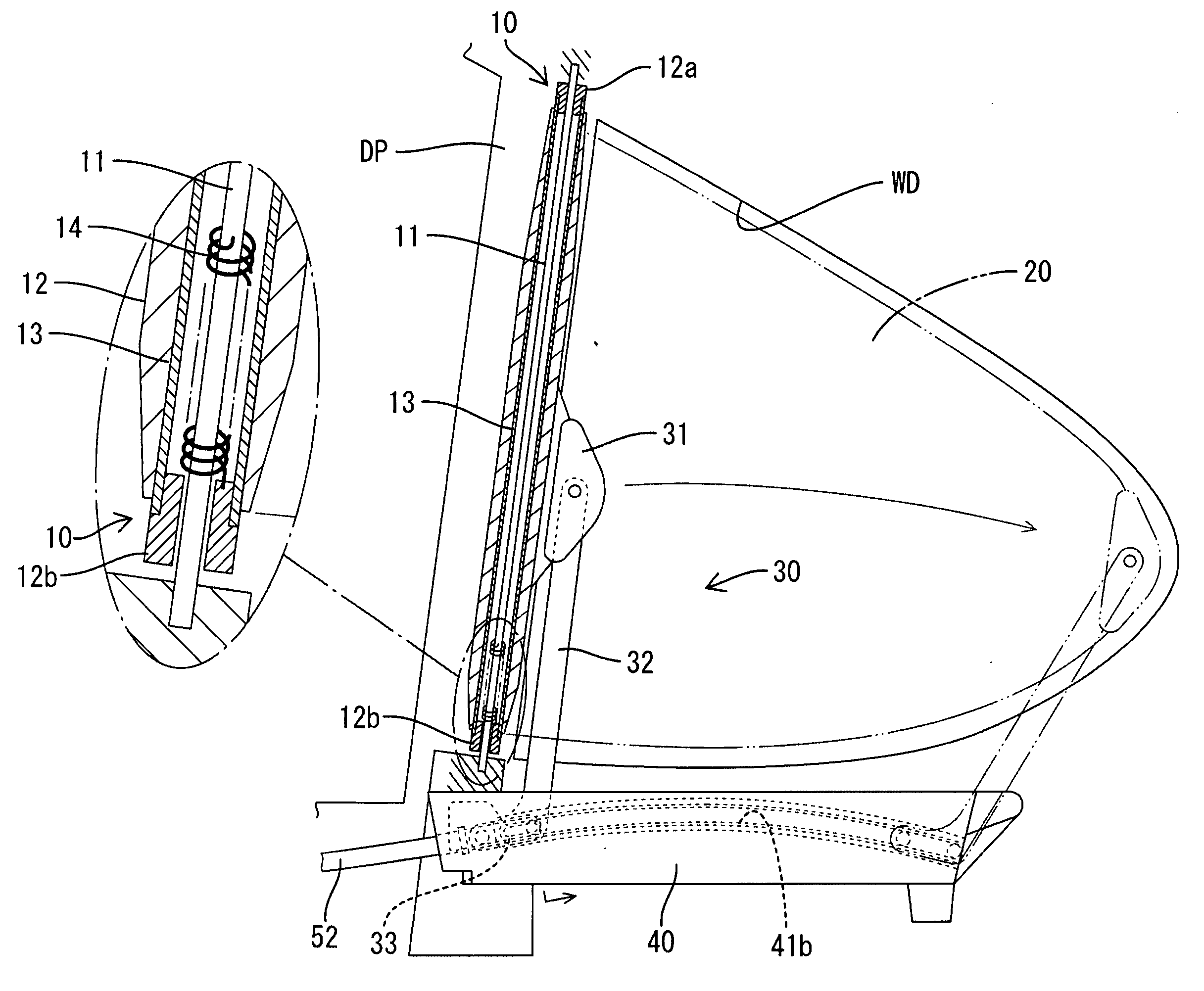

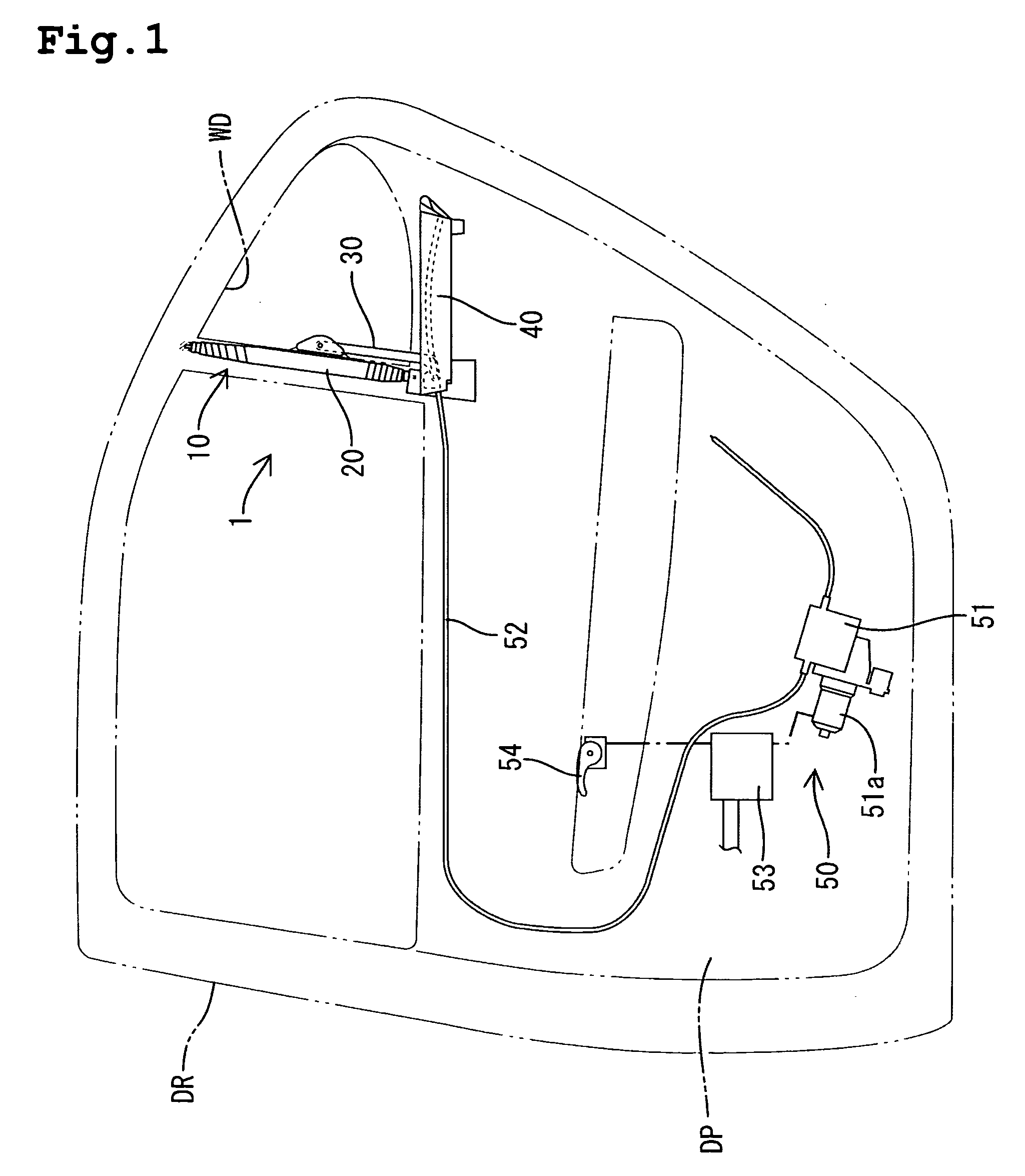

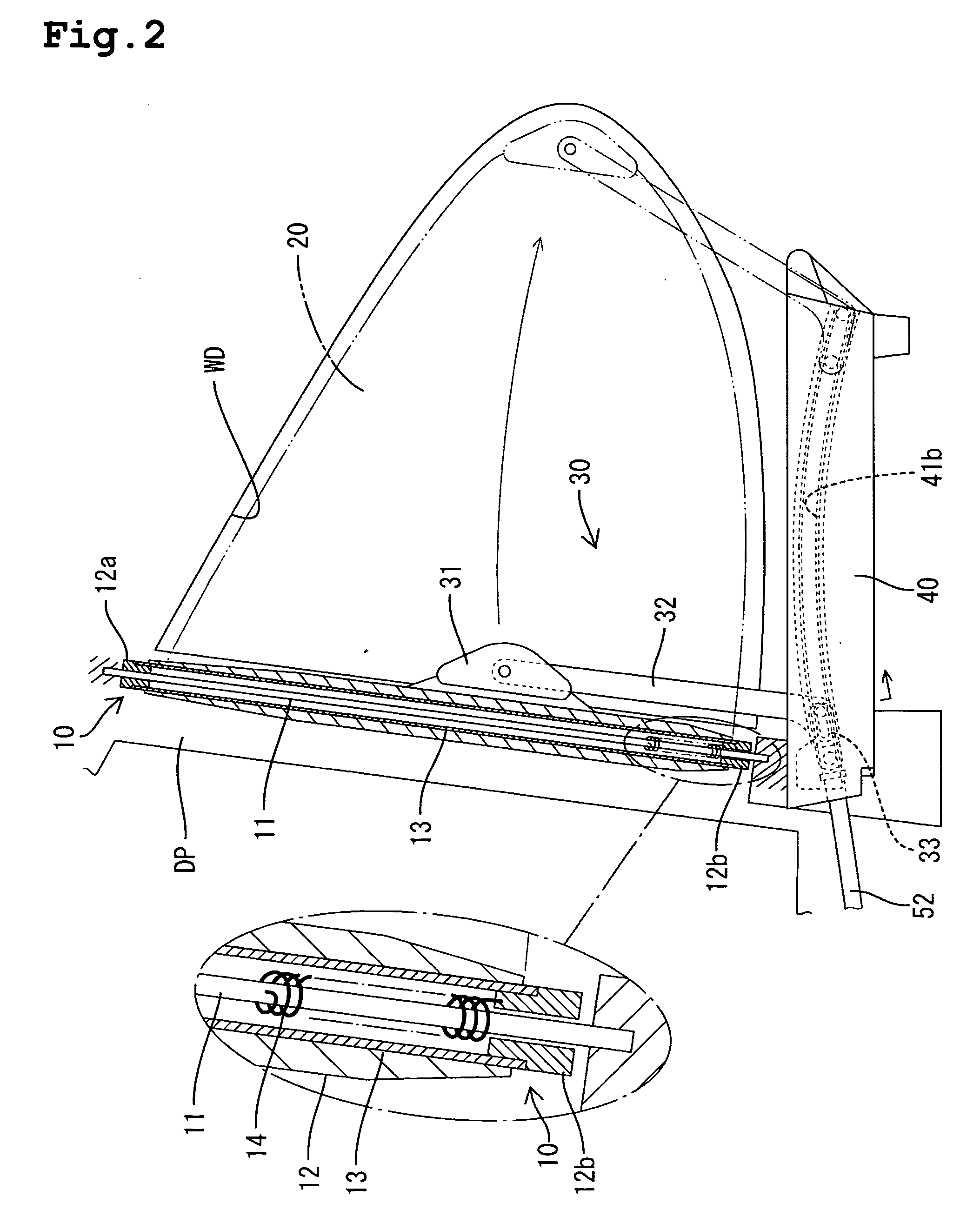

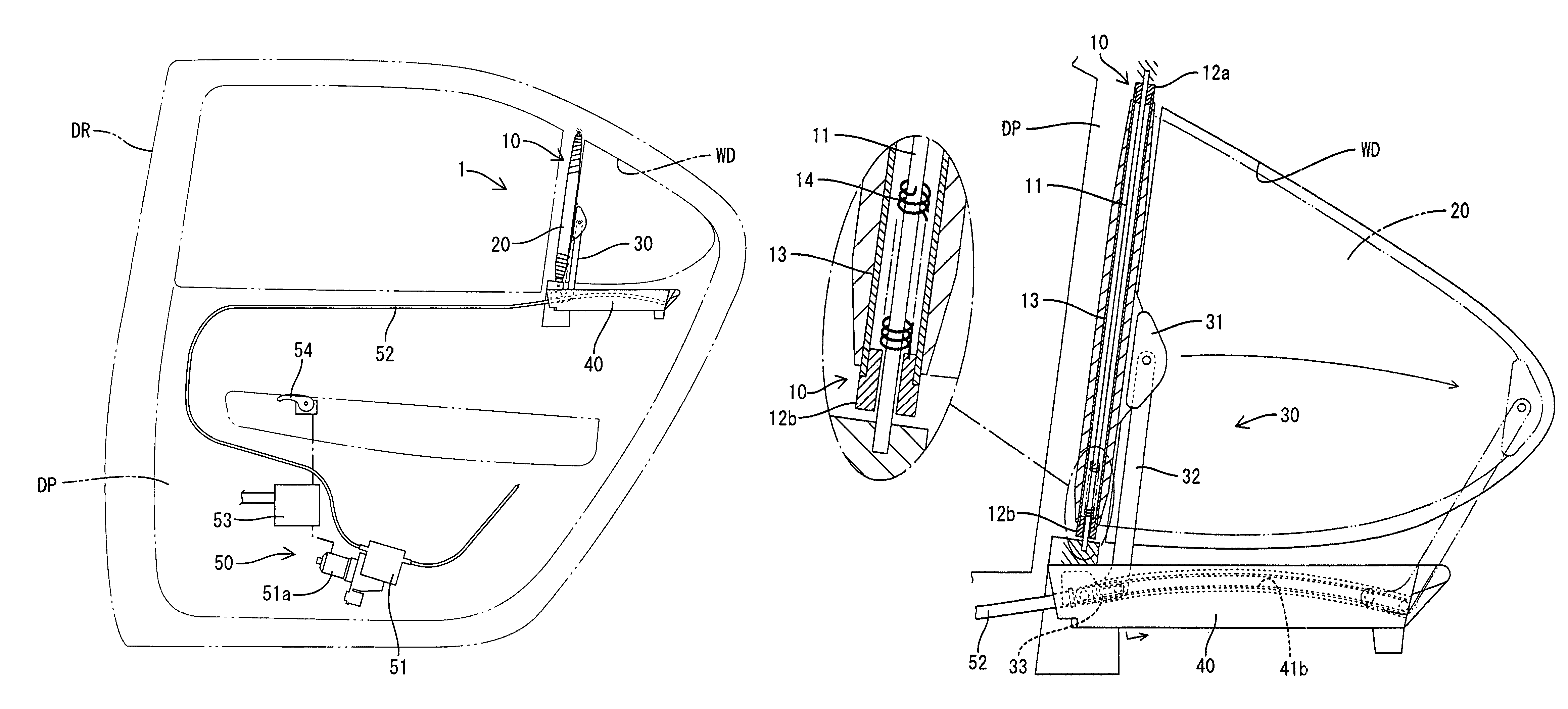

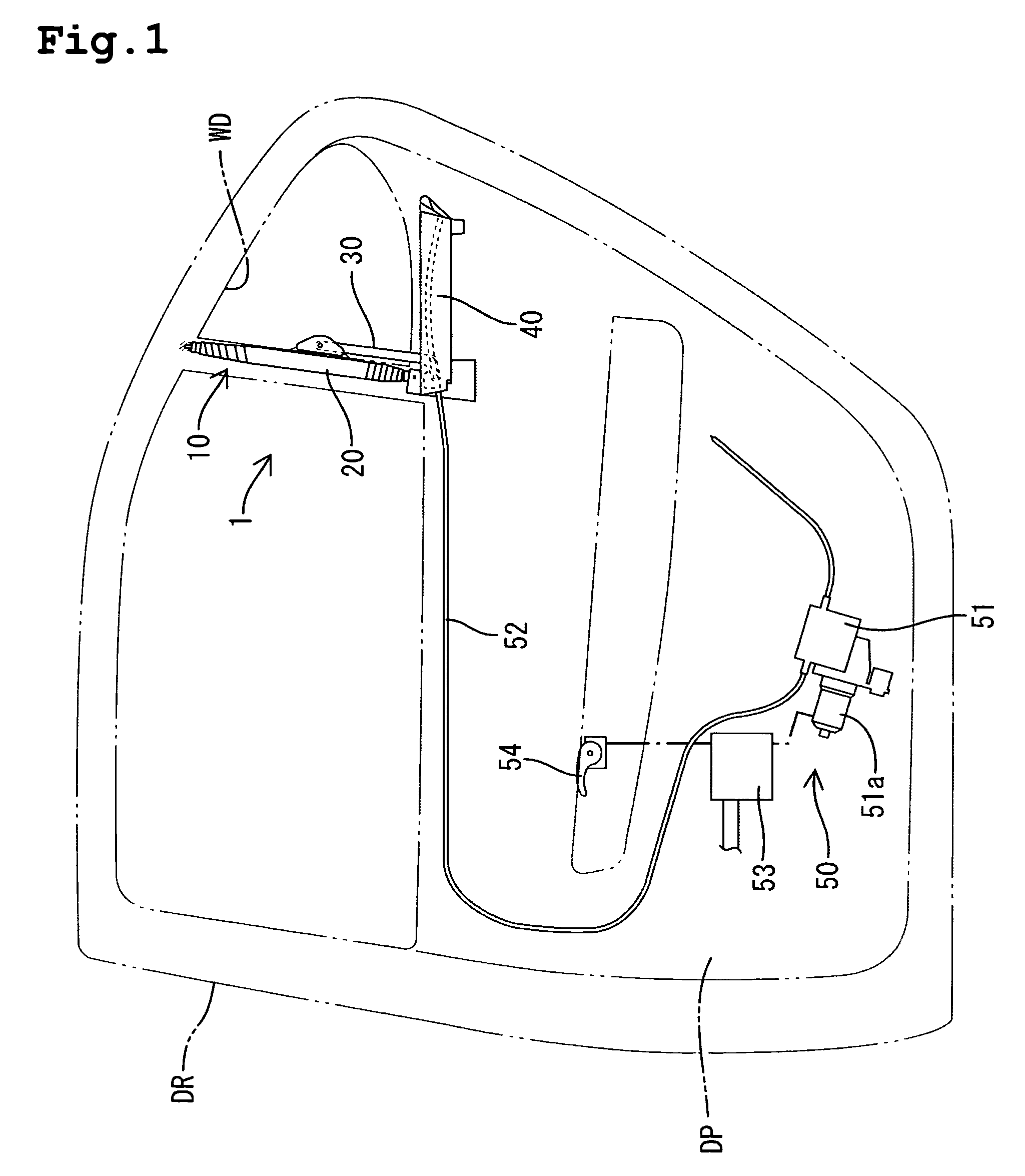

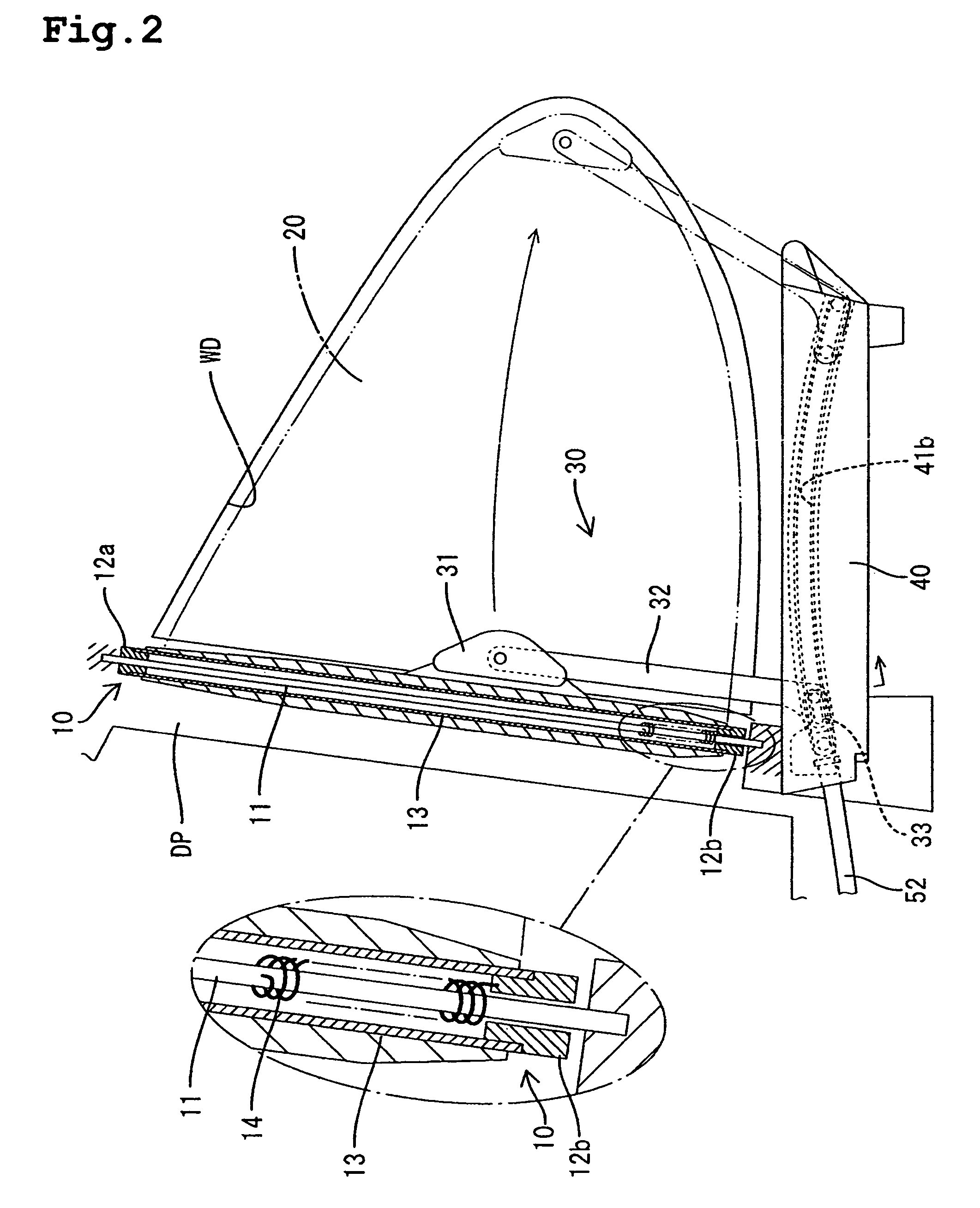

Sunshade actuation device

Owner:TOYOTA BOSHOKU KK +1

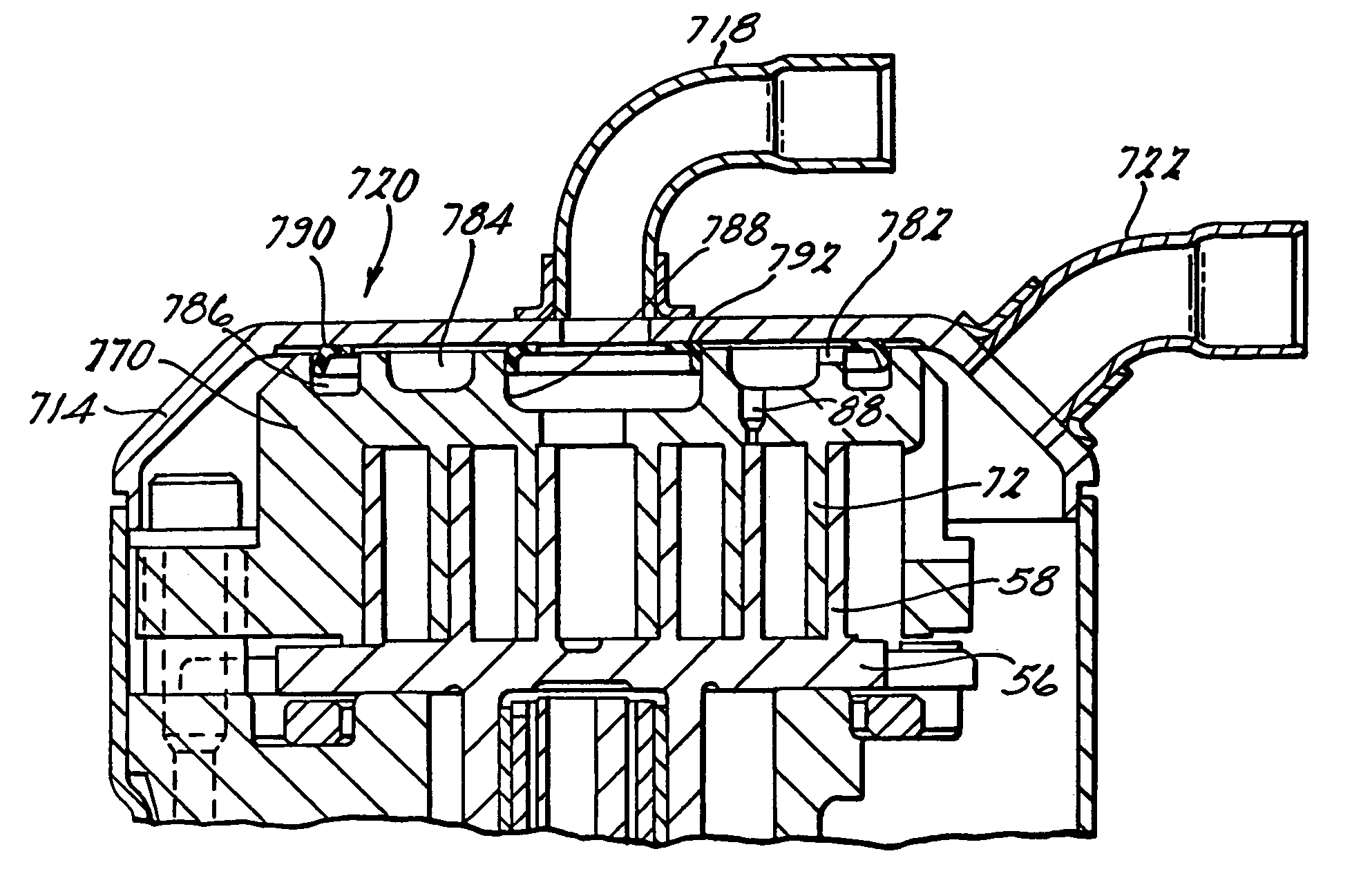

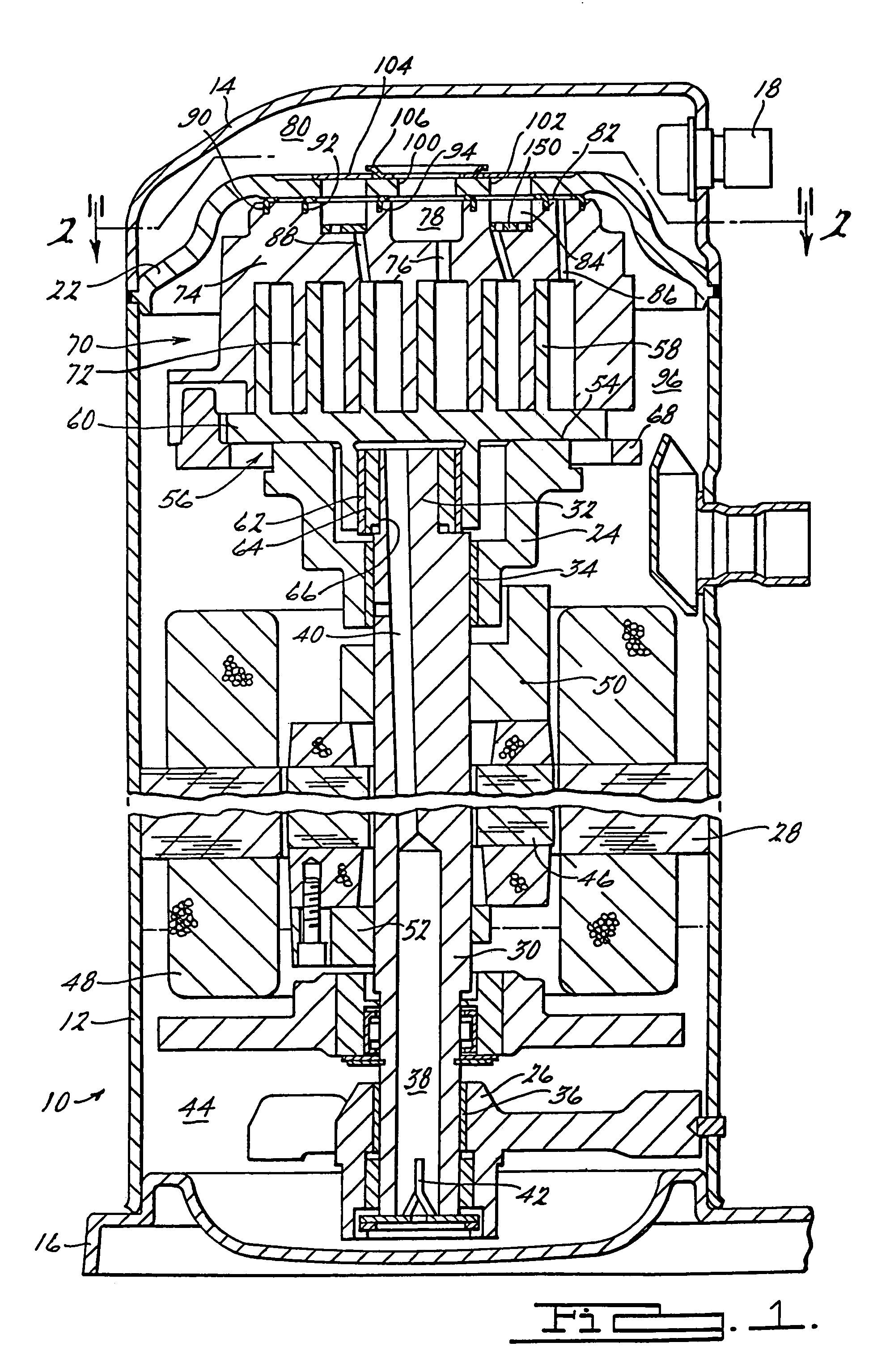

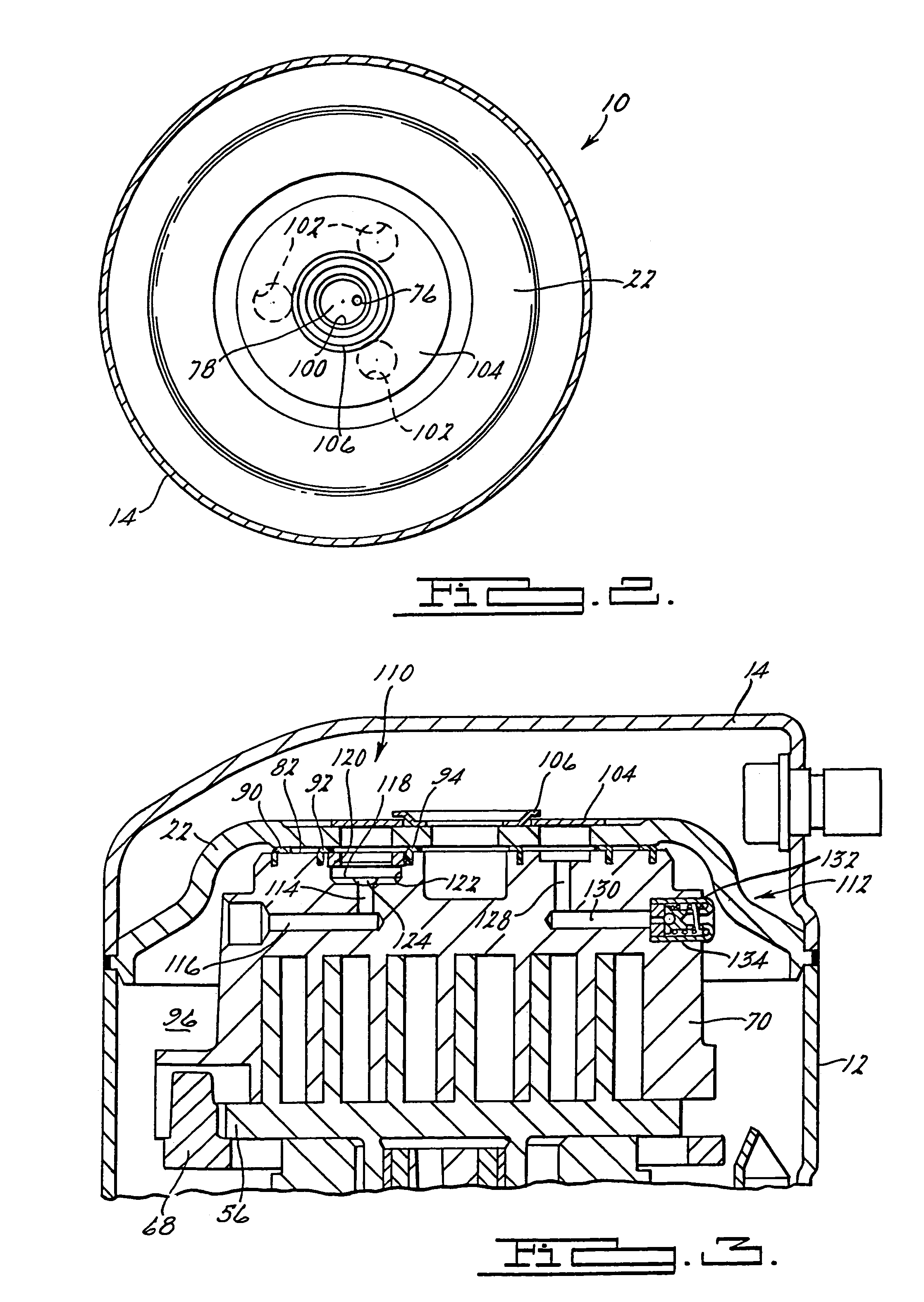

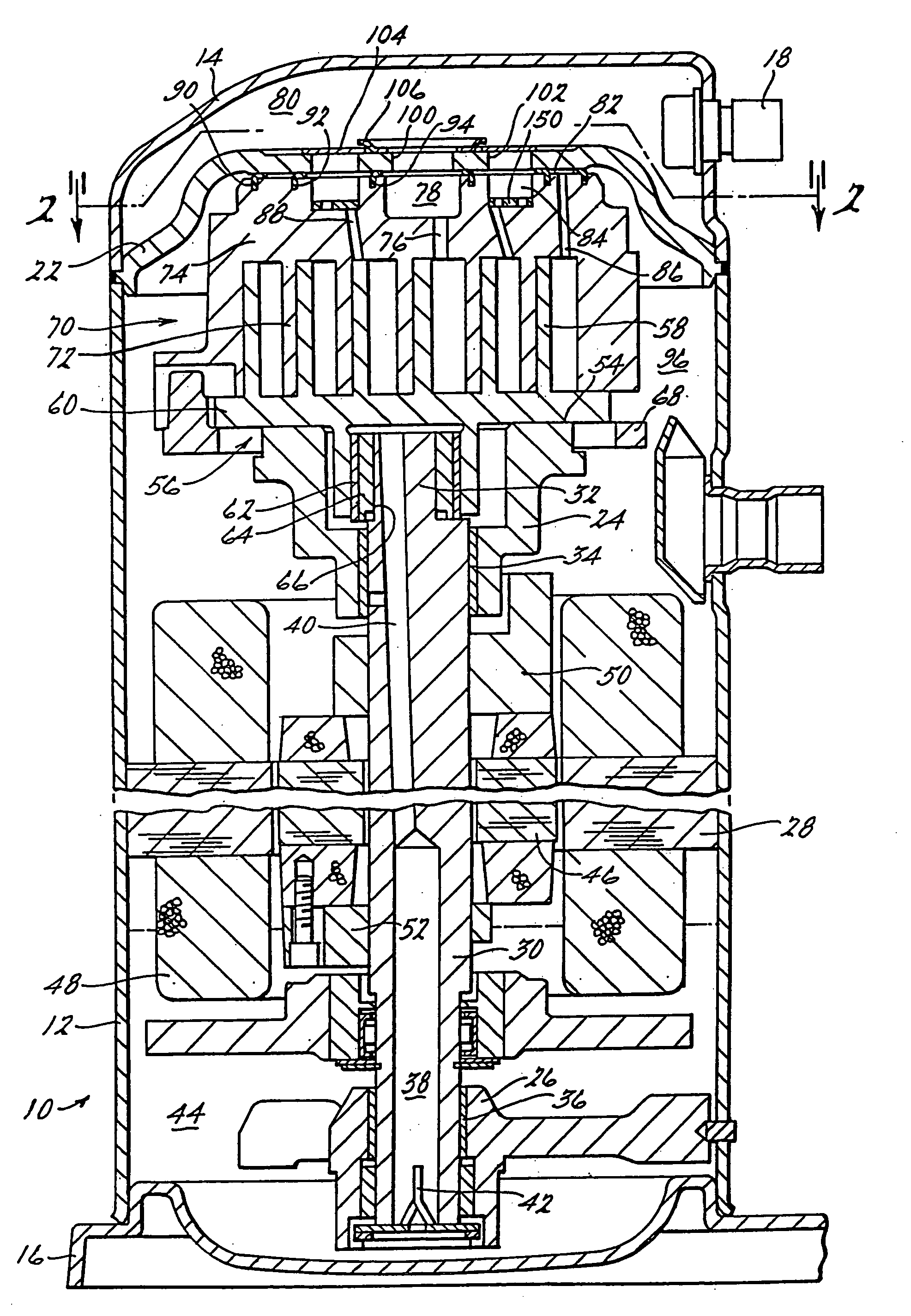

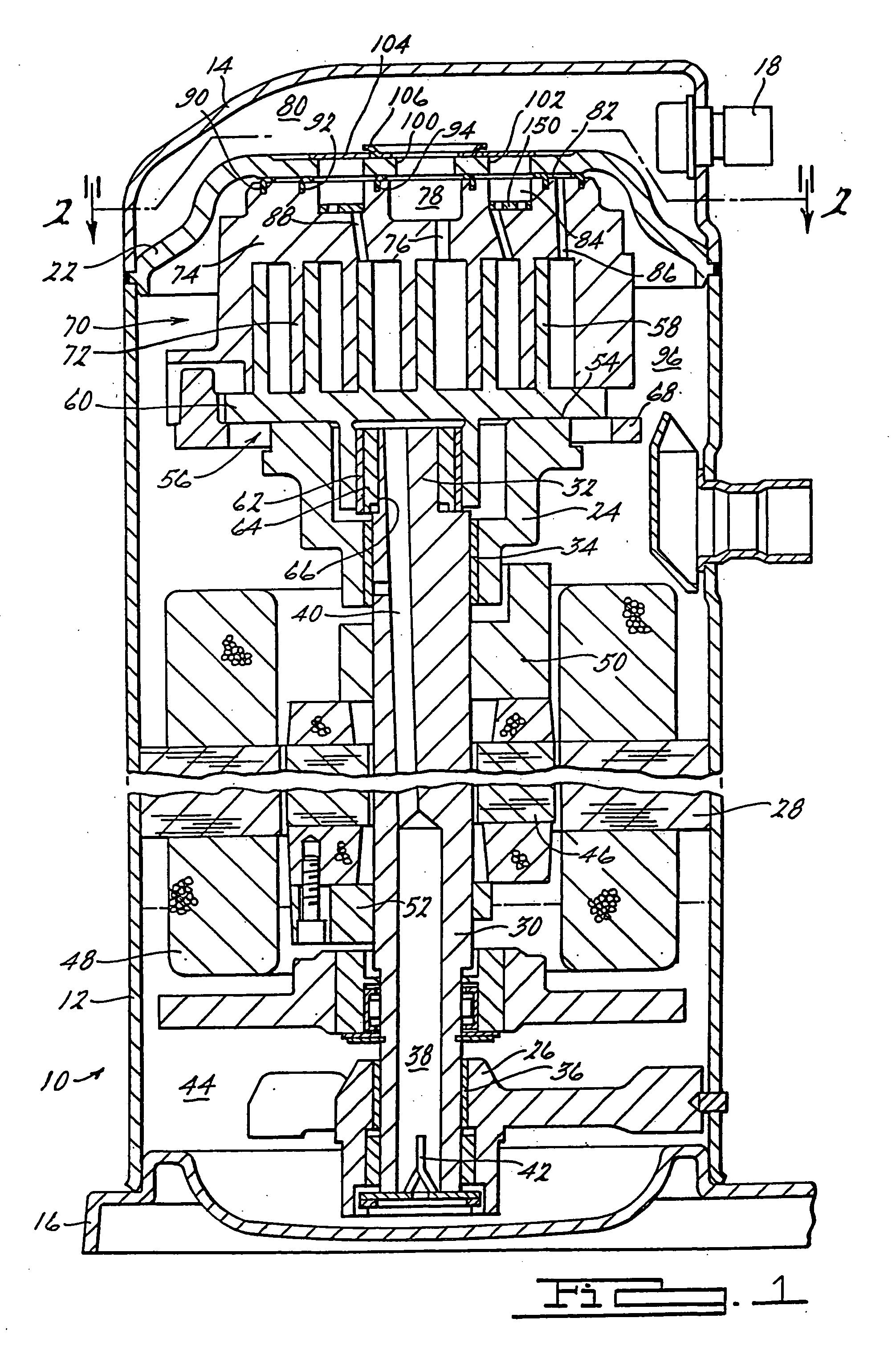

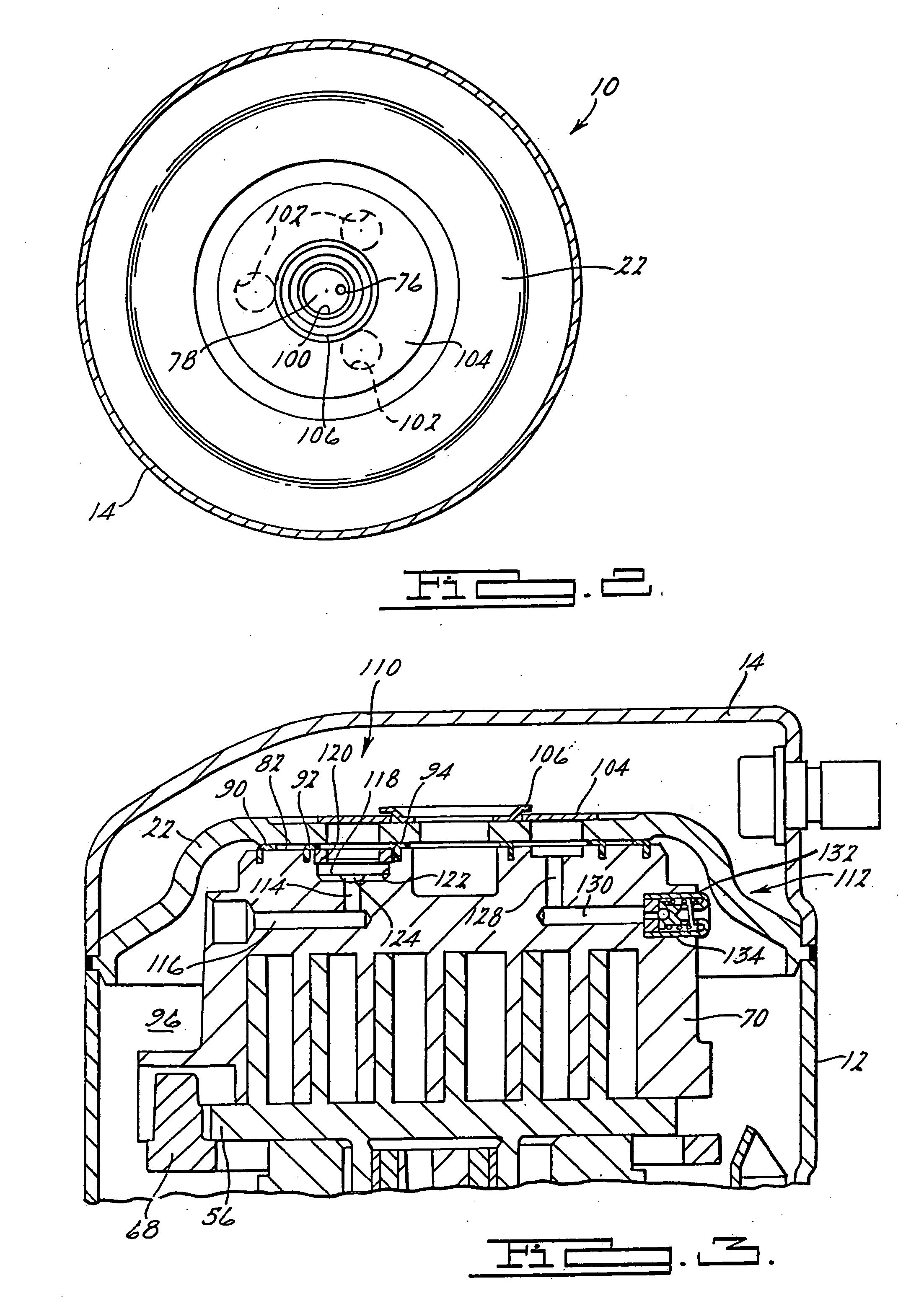

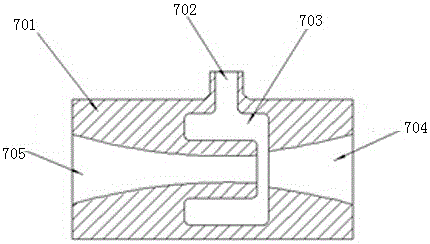

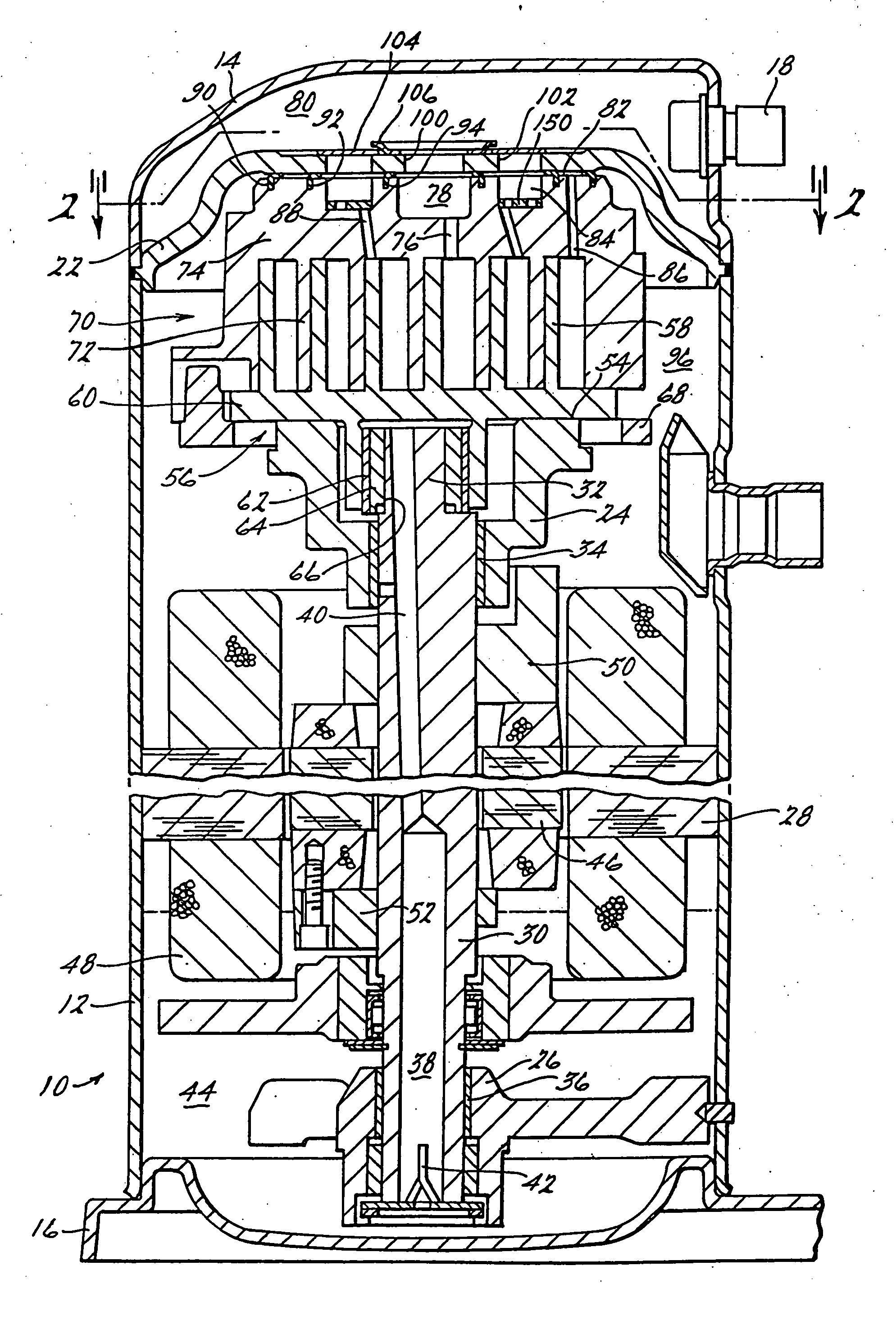

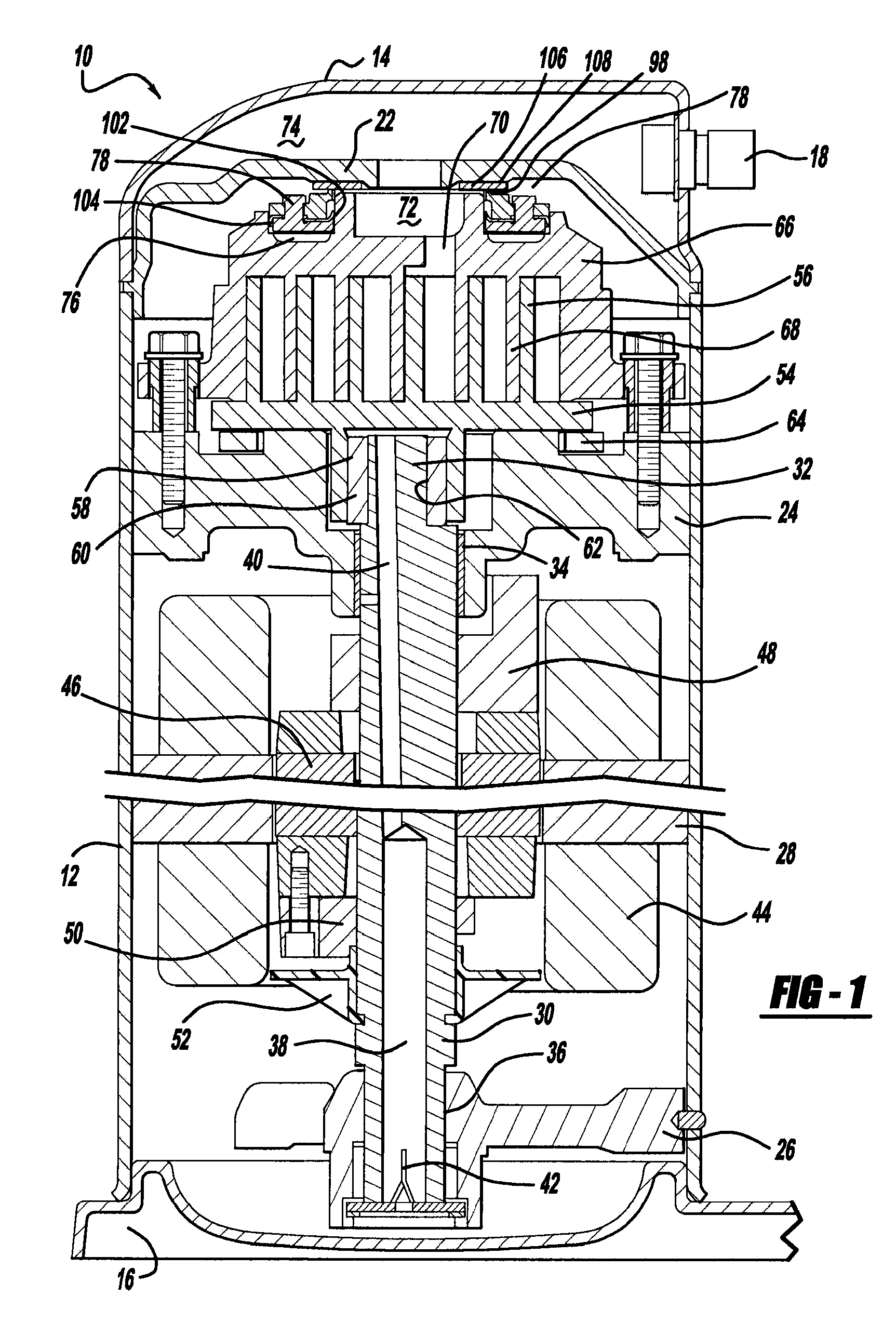

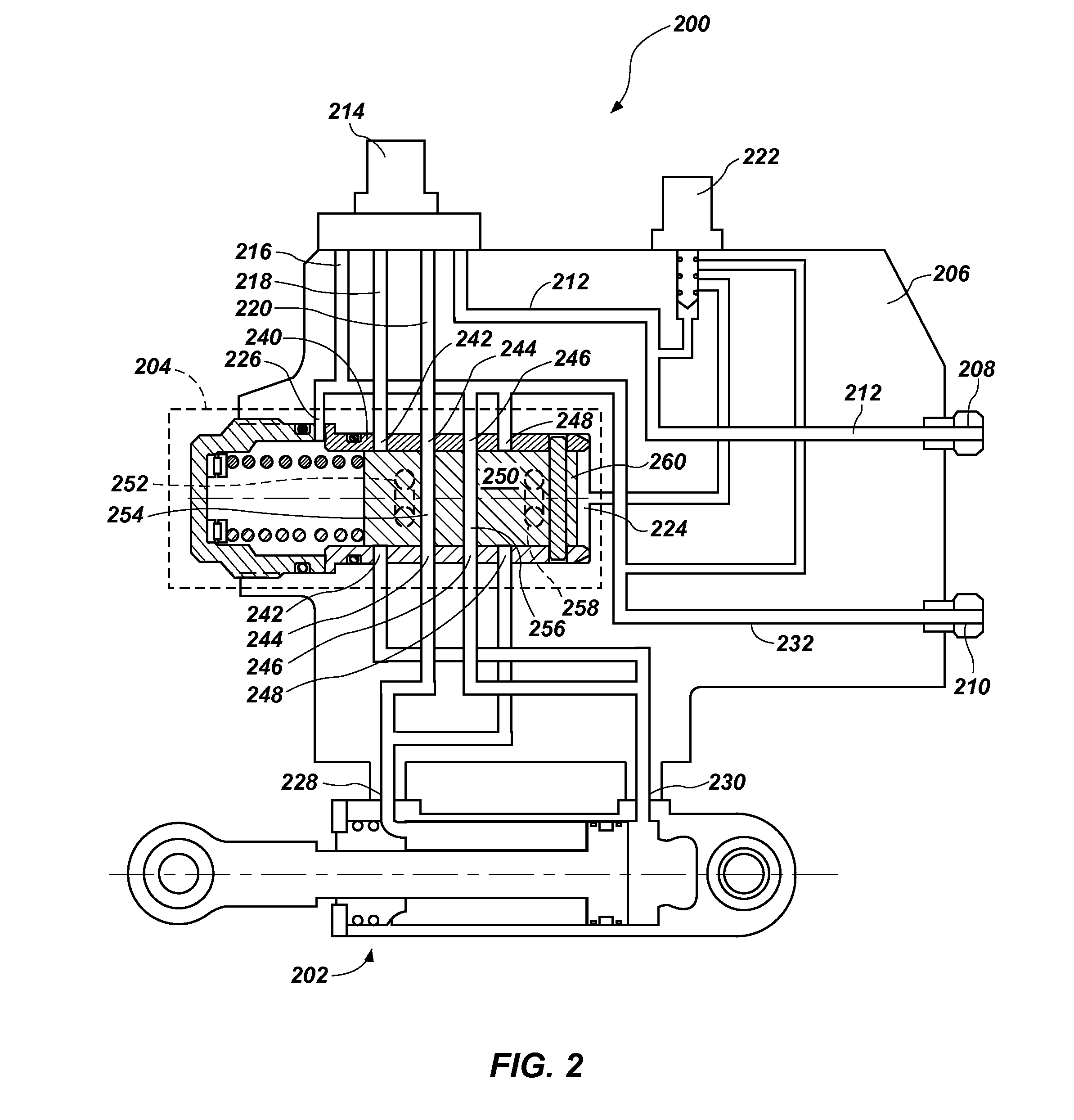

Dual volume-ratio scroll machine

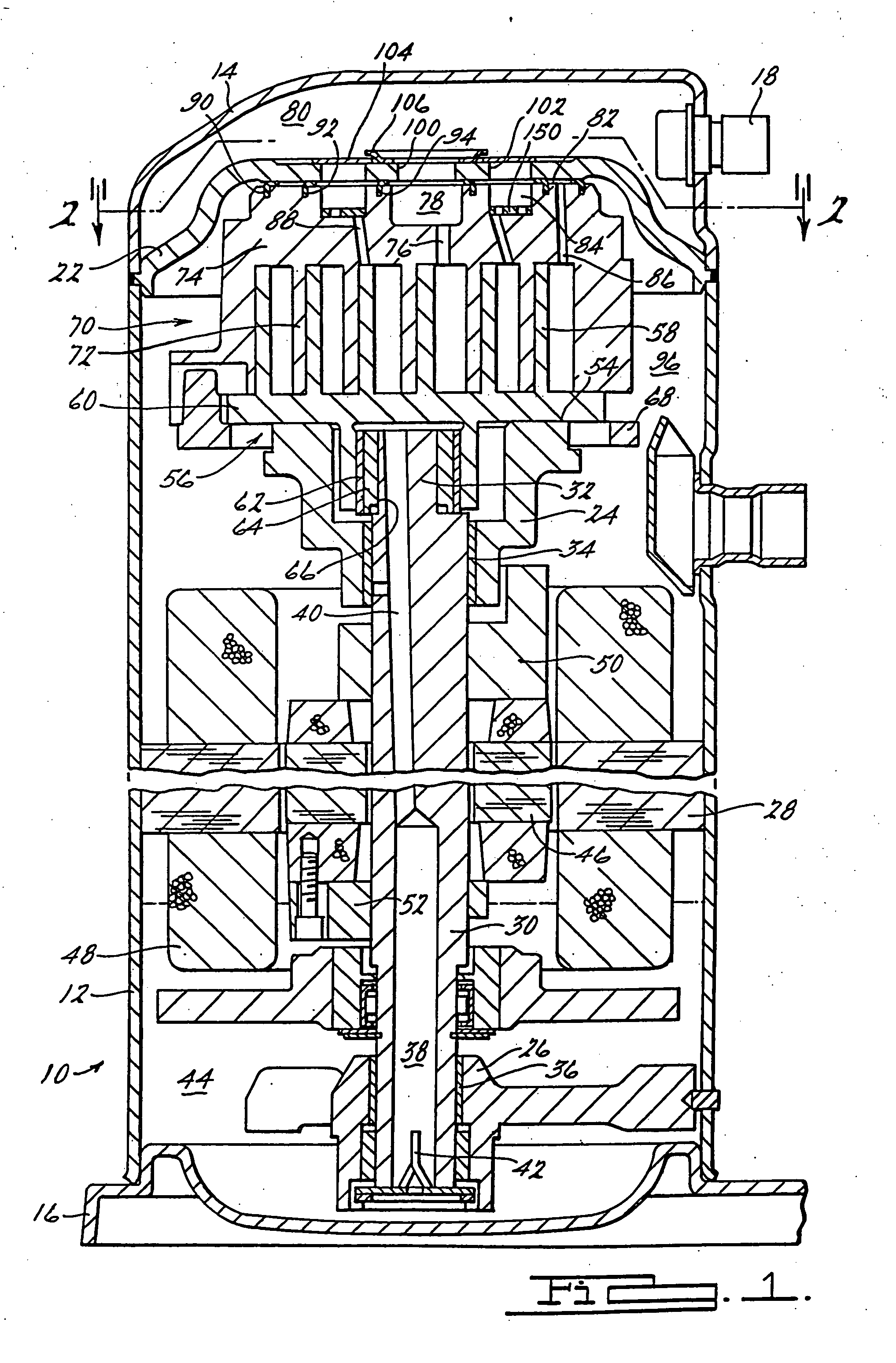

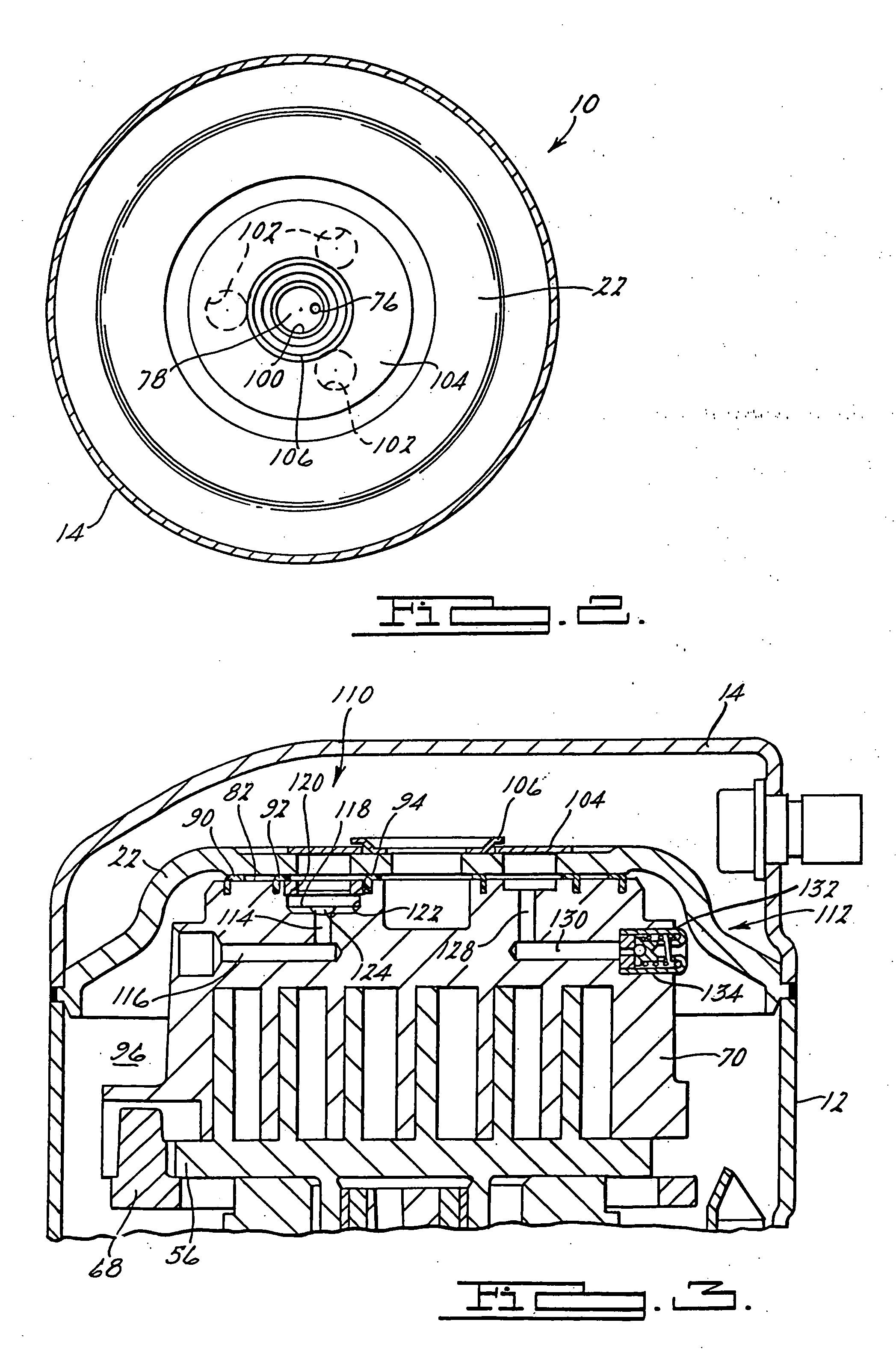

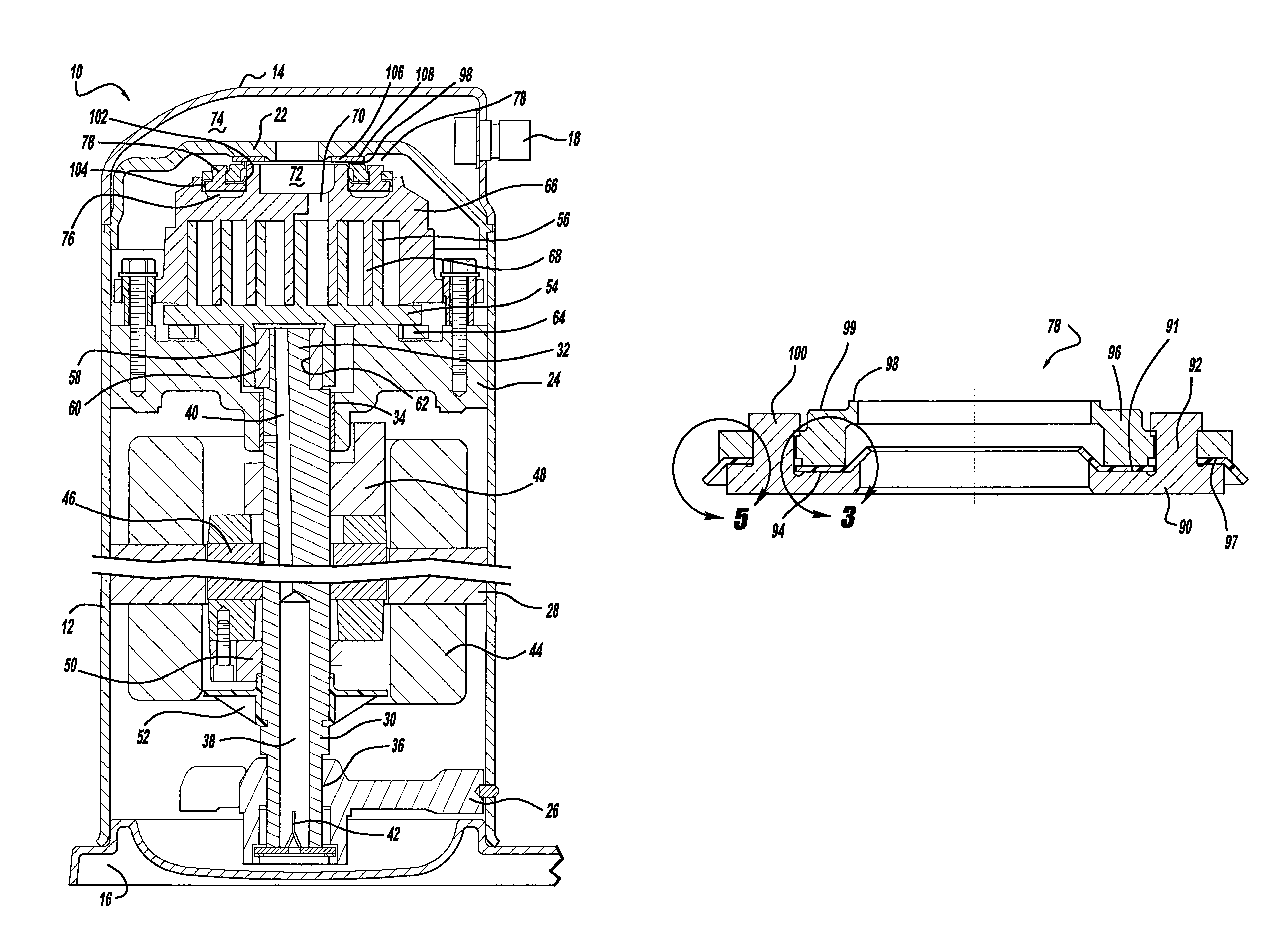

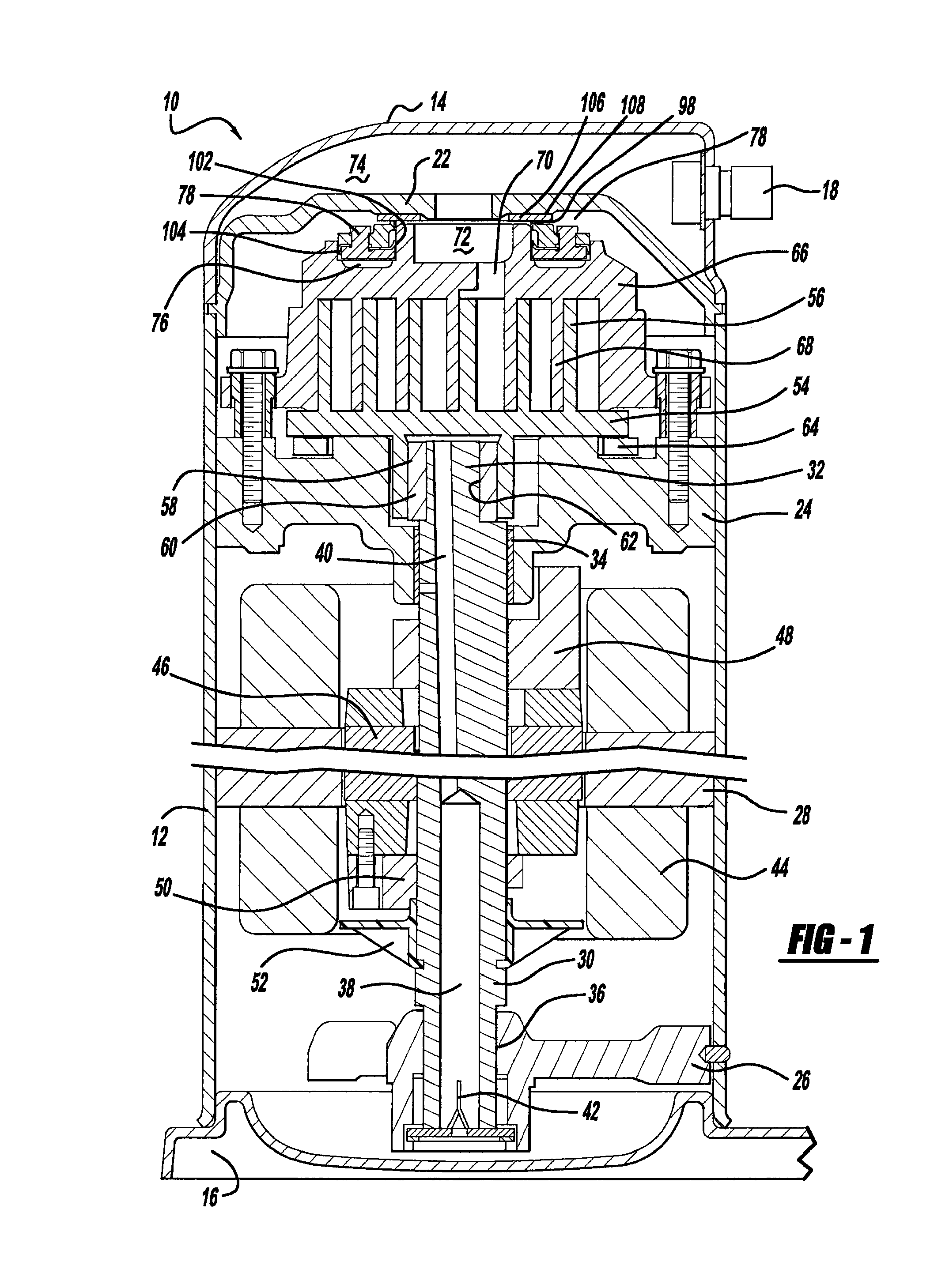

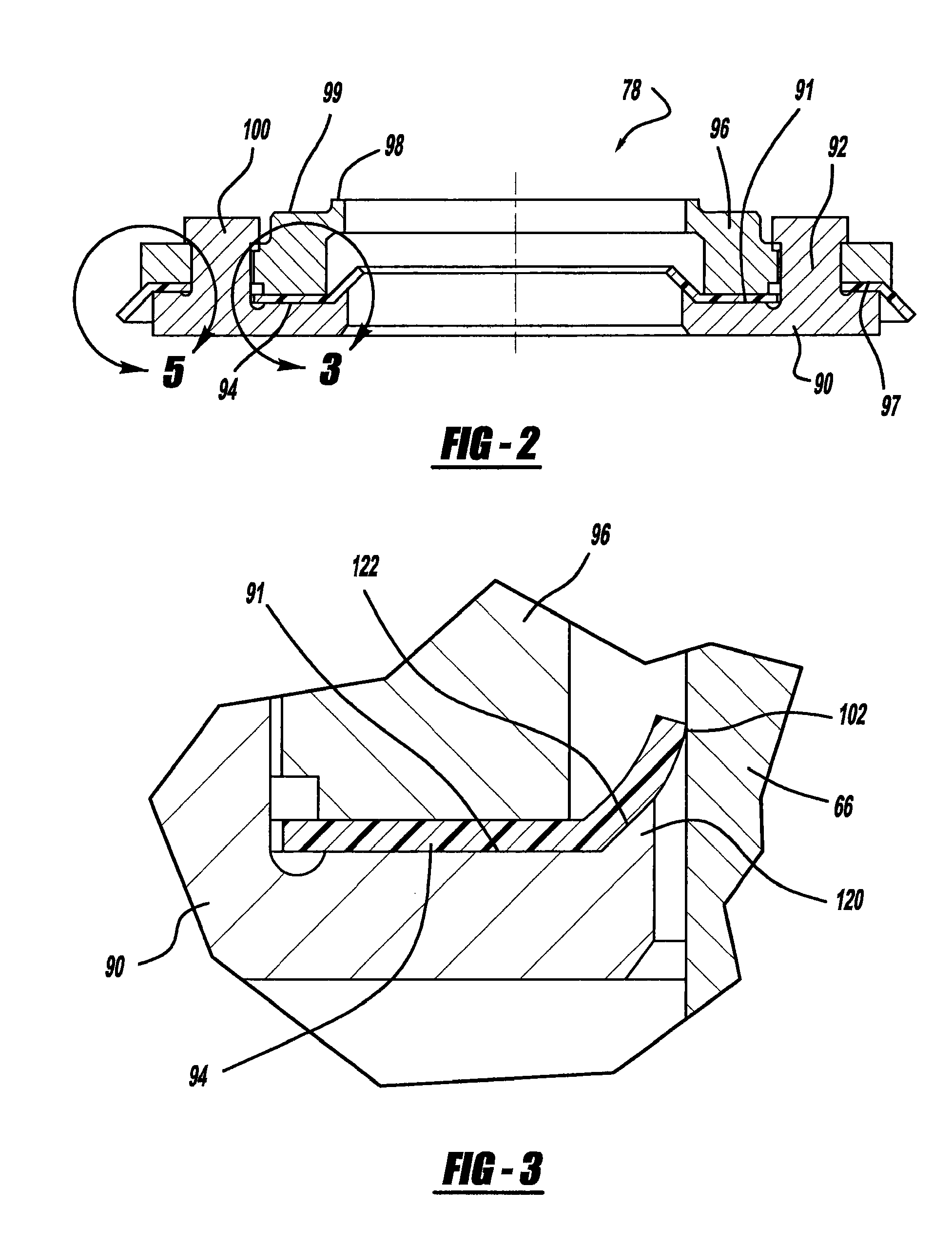

InactiveUS7074013B2Maximize motor efficiencyImprove low voltage operationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringElectrical and Electronics engineering

The present invention provides the art with a scroll machine which has a plurality of built-in volume ratios along with their respective design pressure ratios. The incorporation of more than one built-in volume ratio allows a single compressor to be optimized for more than one operating condition. The operating envelope for the compressor will determine which of the various built-in volume ratios is going to be selected. Each volume ratio includes a discharge passage extending between one of the pockets of the scroll machine and the discharge chamber. All but the highest volume ration utilize a valve controlling the flow through the discharge passage.

Owner:EMERSON CLIMATE TECH INC

Eddy type biomass particle gasification burner

InactiveCN102519034AWill not polluteCompact structureSolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention provides an eddy type biomass particle gasification burner, which belongs to the technical field of fuel equipment and solves the problem that existing burners are low in heat efficiency. The eddy type biomass particle gasification burner comprises a casing with an air chamber, a first combustion chamber and a second combustion chamber, wherein the first combustion chamber with a feed inlet and the second combustion chamber communicated with the first combustion chamber are arranged in the casing, a round flame tube is connected to the upper end of the second combustion chamber, a flame outlet at the outer end of the round flame tube extends out of the casing, an annular sleeve is sleeved on a portion, extending out of the casing, of the round flame tube, an interlayer for air and oxygen compensation for combustion is formed between the annular sleeve and the round flame tube, and the interlayer is provided with an air supply hole communicated with the air chamber. The eddy type biomass particle gasification burner has the advantages of compact structure, high heat efficiency and the like.

Owner:浙江蓝宝精灵环境科技有限公司

Sunshade actuation device

Owner:TOYOTA BOSHOKU KK +1

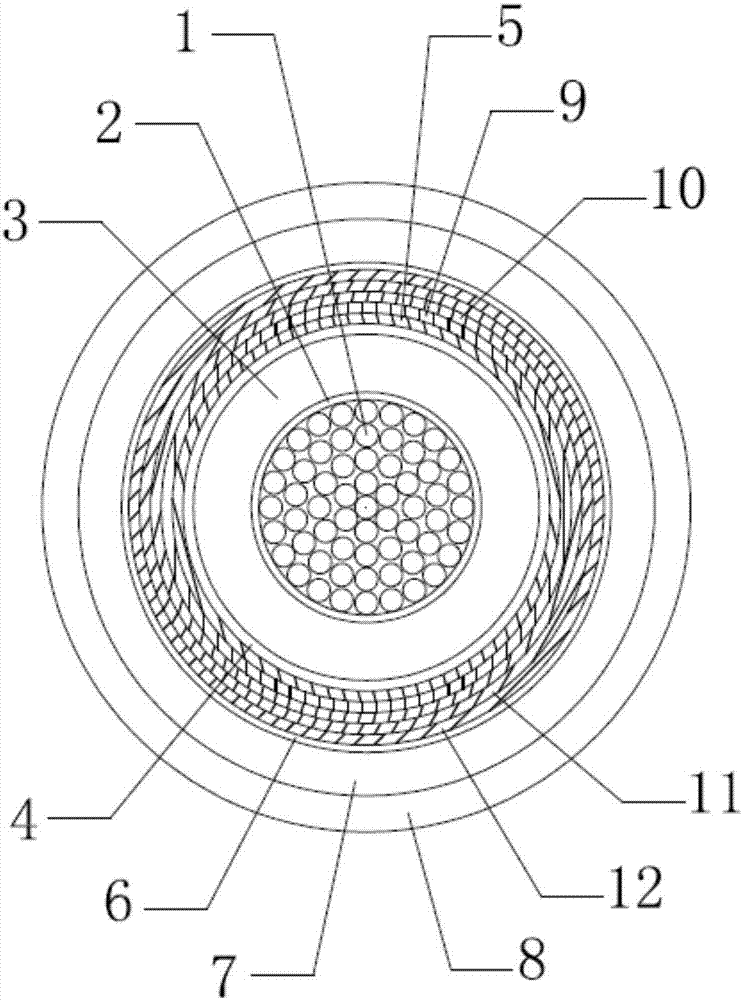

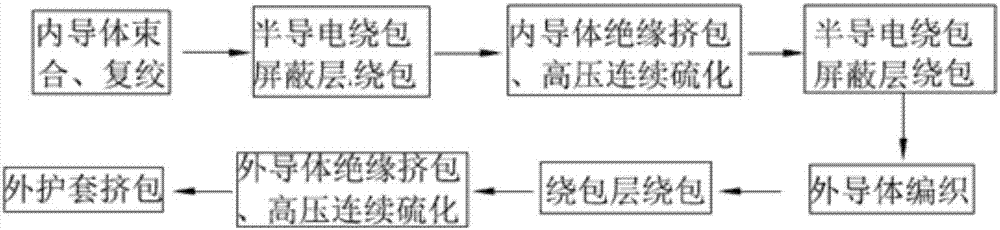

Manufacturing method of cable for high power transmission equipment and cable

InactiveCN107154285ANo damageReduce weightConcentric cablesPower cables with screens/conductive layersReliable transmissionElectrical conductor

A cable for high power transmission equipment, its structure from inside to outside is: inner conductor, first semiconductive wrapping shielding layer, inner conductor insulation, second semiconducting wrapping shielding layer, outer conductor, wrapping layer, Outer conductor insulation and outer sheath. The insulating layer of the inner conductor is made of silicon rubber; the outer conductor is braided with one or more layers of tinned copper wire; the insulating layer of the outer conductor is made of silicon rubber; the outer sheath layer is made of polyurethane. The manufacturing method of the cable comprises: 1) manufacturing the inner conductor; 2) manufacturing the first semiconductive wrapping shielding layer; 3) manufacturing the inner conductor insulating layer; 4) manufacturing the second semiconductive wrapping shielding layer; 5) manufacturing 6) manufacturing the wrapping layer; 7) manufacturing the insulating layer of the outer conductor; 8) manufacturing the outer sheath layer. In each step, a specific process method is adopted, so that the electrical and mechanical properties of the cable prepared by this method can meet or exceed the detection requirements, so that the cable for high-power transmission equipment can transmit high power safely and reliably, and has the advantages of light weight. , miniaturization, low temperature resistance, good flexibility, small bending radius and other excellent performances, suitable for high electric energy technical equipment.

Owner:JIANGSUSNGSHANG CABLE GROUP

Dual volume-ratio scroll machine

InactiveUS20060204380A1Improve reliability and durabilitySlow downRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsOperant conditioningMechanical engineering

Owner:EMERSON CLIMATE TECH INC

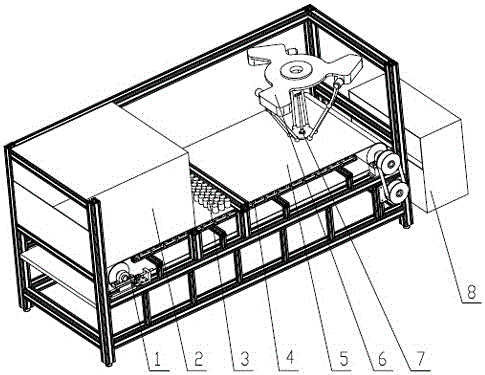

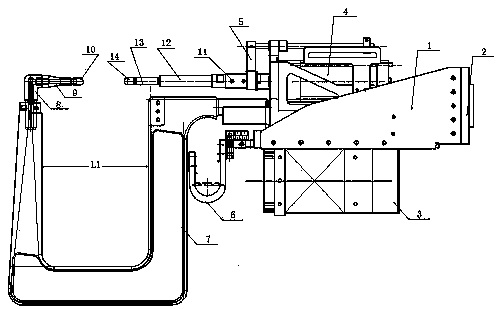

Intelligent high-speed down feather color selector

InactiveCN105855189AEasy to operateReduce volumeSortingConveyor partsEngineeringElectrical and Electronics engineering

The invention discloses an intelligent high-speed down feather color selector and belongs to the technical field of down feather processing. The intelligent high-speed down feather color selector comprises a down feather conveyor belt. The down feather conveyor belt is sequentially divided into a down feather charging section, a detecting section, a sorting section and a down feather collecting section. A down feather supply box is arranged on the down feather charging section. A detection lens array is arranged on the detecting section. A DELTA robot is arranged on the sorting section and is provided with a sorting head. A down feather sucking box is arranged on one side of the down feather collecting section. Micro converter fans are arranged under the down feather charging section, the detecting section, the sorting section and the down feather collecting section correspondingly. According to the intelligent high-speed down feather color selector, automatic down feather color selection is achieved, operation is convenient, and the intelligent high-speed down feather color selector is small in size, light, handy, convenient, fast and suitable for large-scale application and popularization. By adopting the intelligent high-speed down feather color selector, the labor intensity of down feather color selection is relieved, the problem that the efficiency of manual selection is not high is solved, the production efficiency is improved, and the precision of down feather color selection is improved.

Owner:浙江钧工智能科技有限公司 +1

Dual volume-ratio scroll machine

InactiveUS20060204379A1Improve reliability and durabilitySlow downRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectrical and Electronics engineeringTraffic volume

The present invention provides the art with a scroll machine which has a plurality of built-in volume ratios along with their respective design pressure ratios. The incorporation of more than one built-in volume ratio allows a single compressor to be optimized for more than one operating condition. The operating envelope for the compressor will determine which of the various built-in volume ratios is going to be selected. Each volume ratio includes a discharge passage extending between one of the pockets of the scroll machine and the discharge chamber. All but the highest volume ration utilize a valve controlling the flow through the discharge passage.

Owner:EMERSON CLIMATE TECH INC

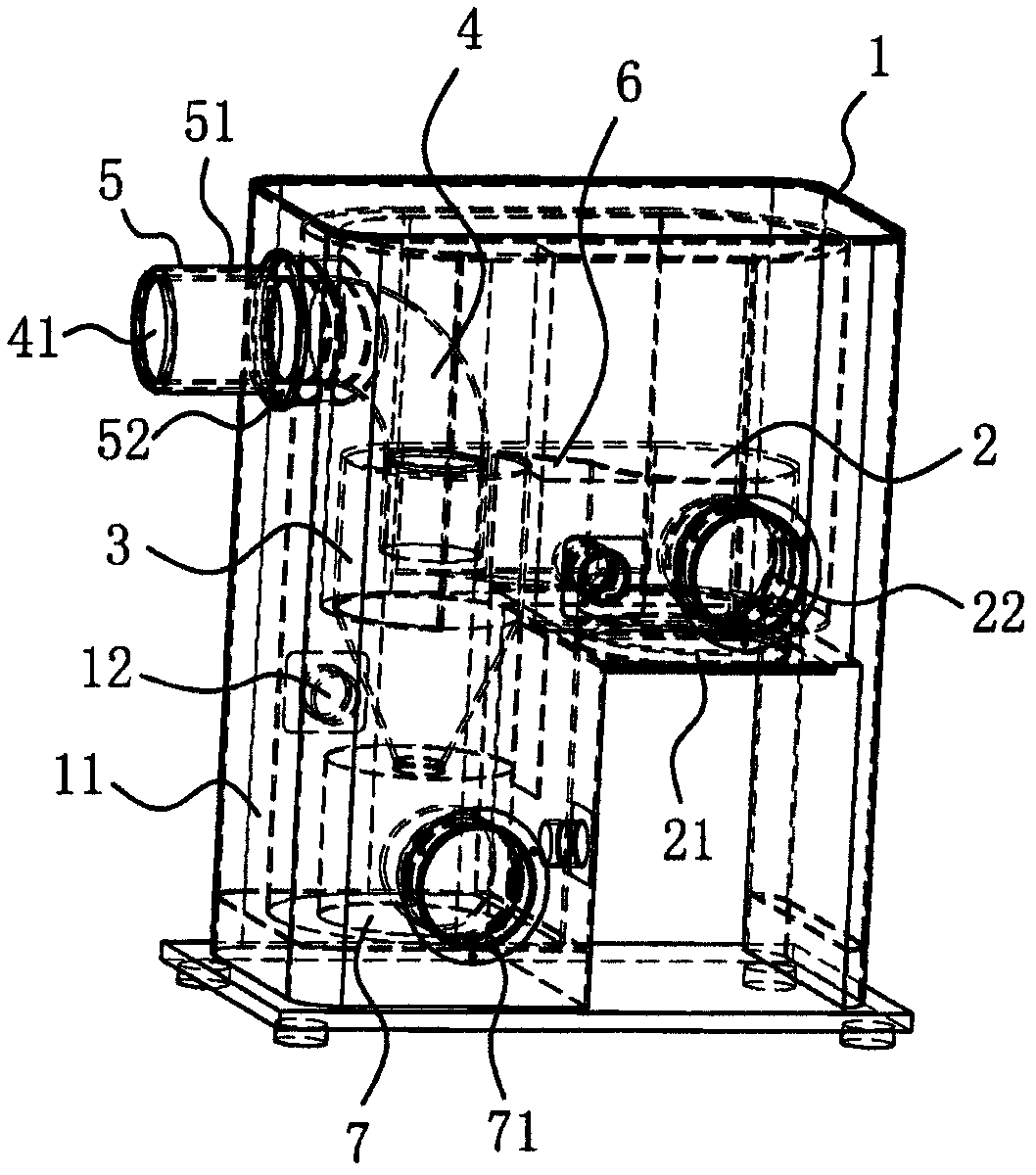

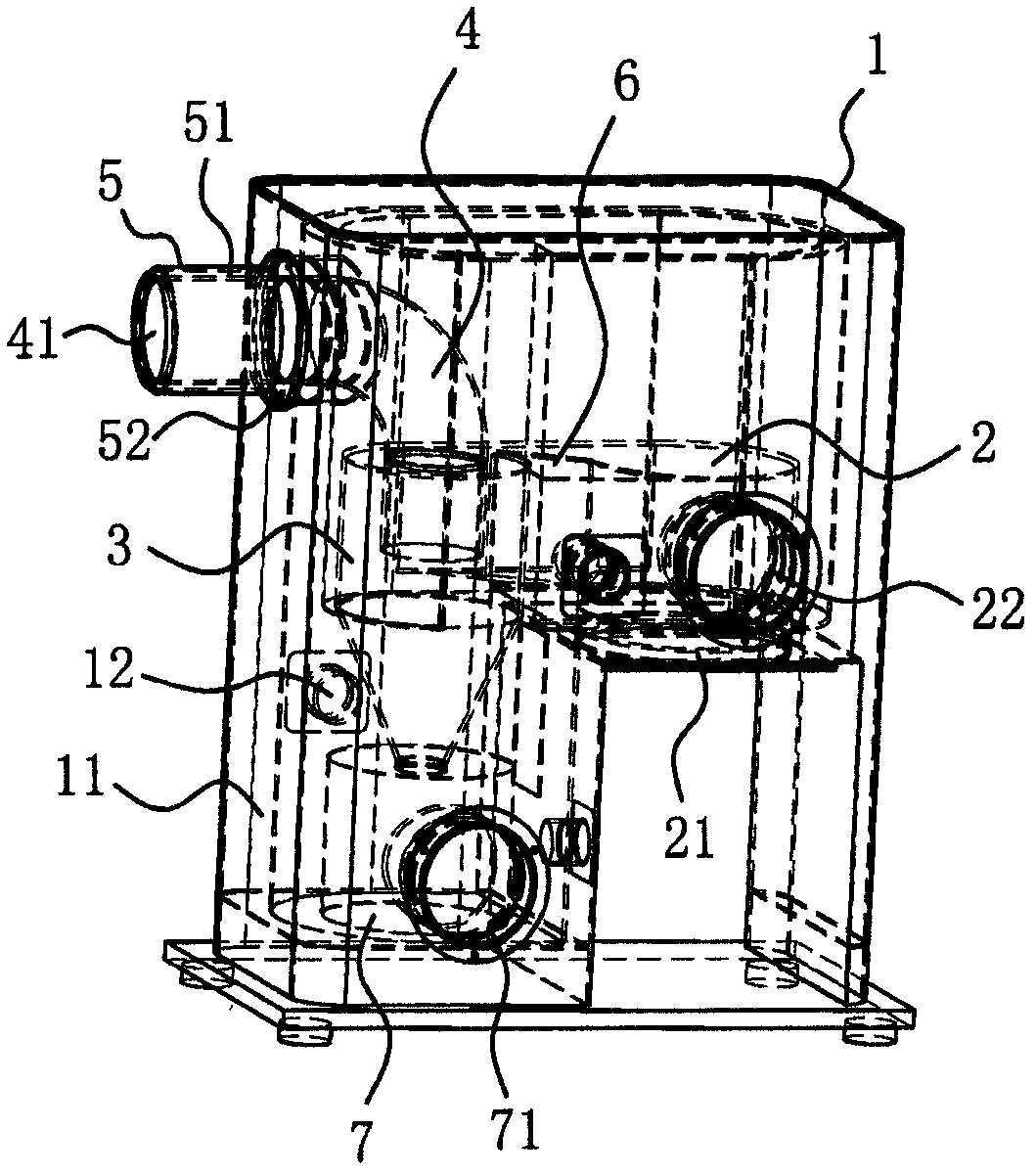

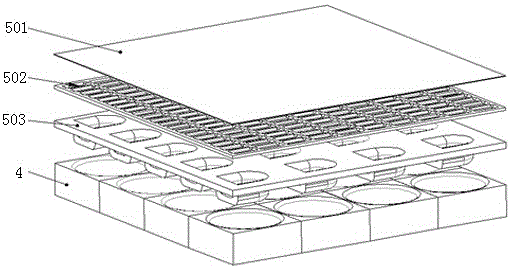

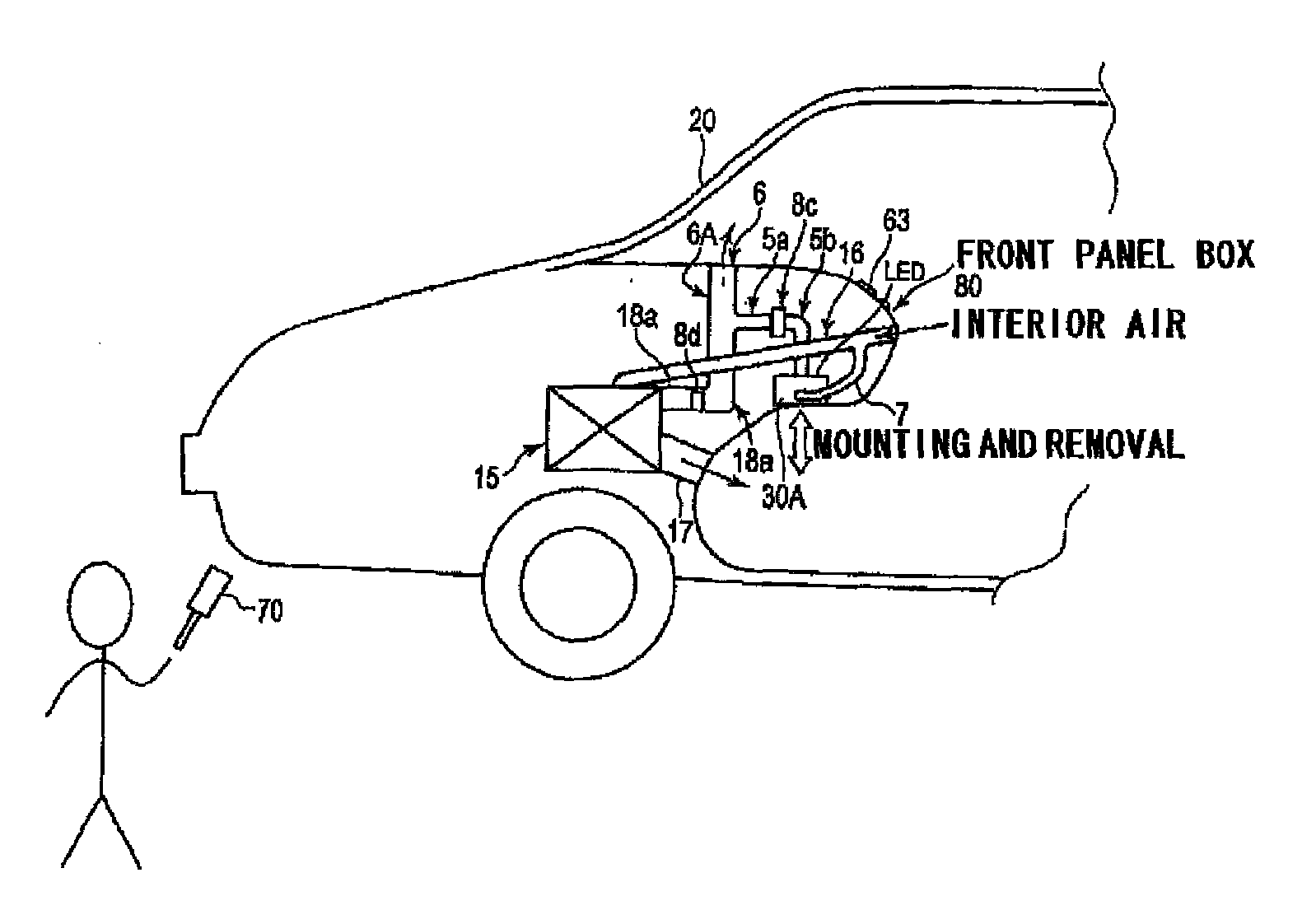

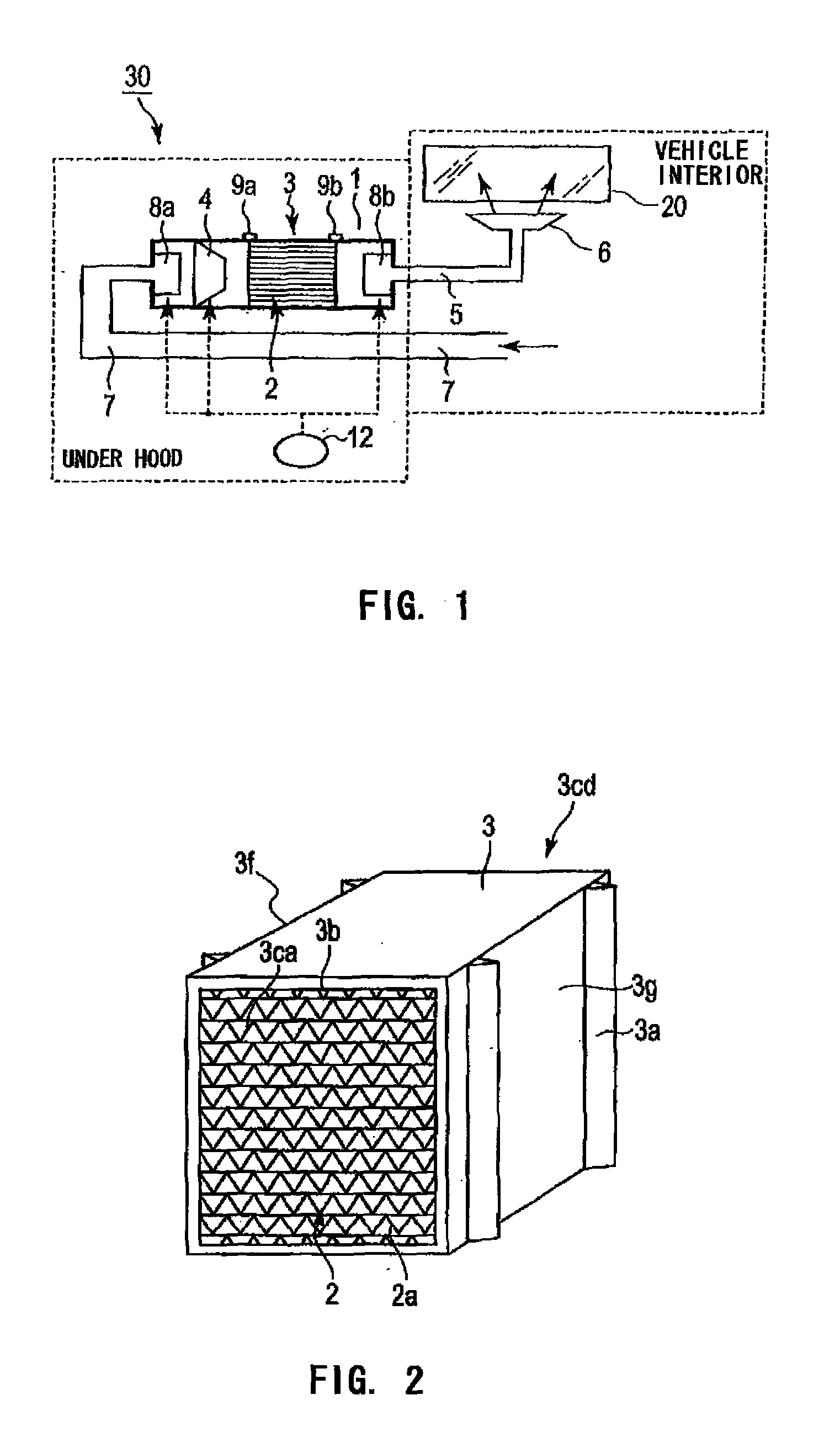

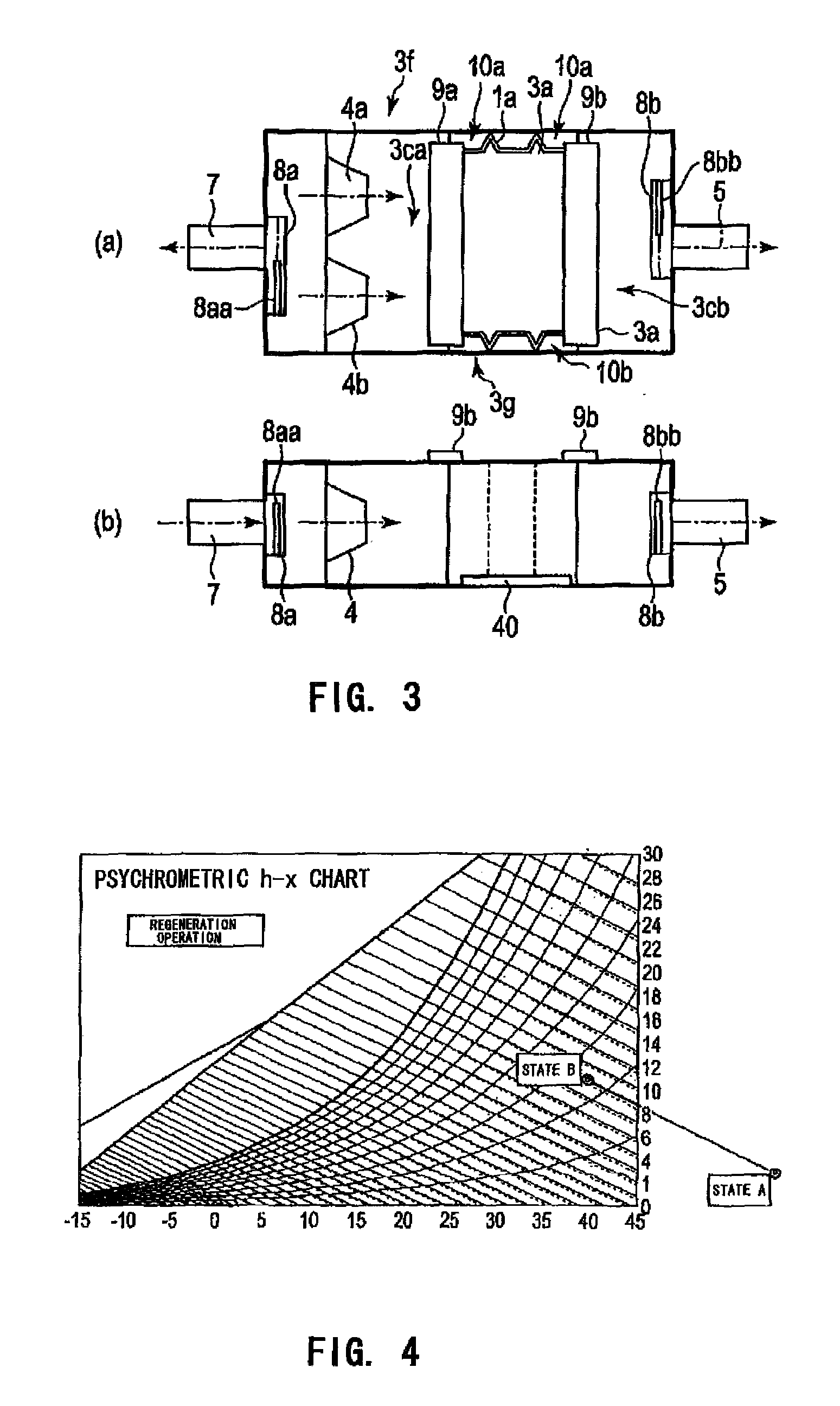

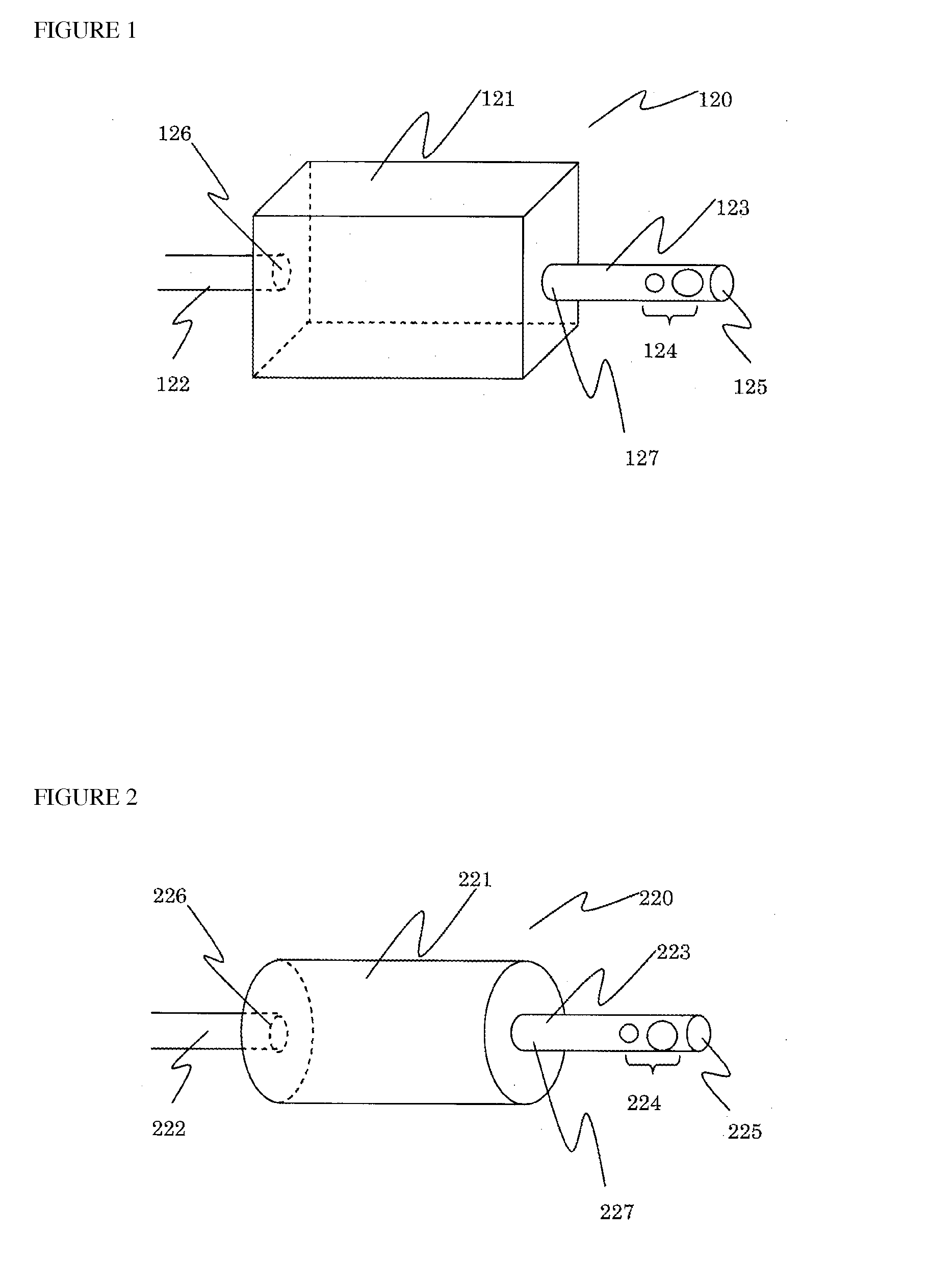

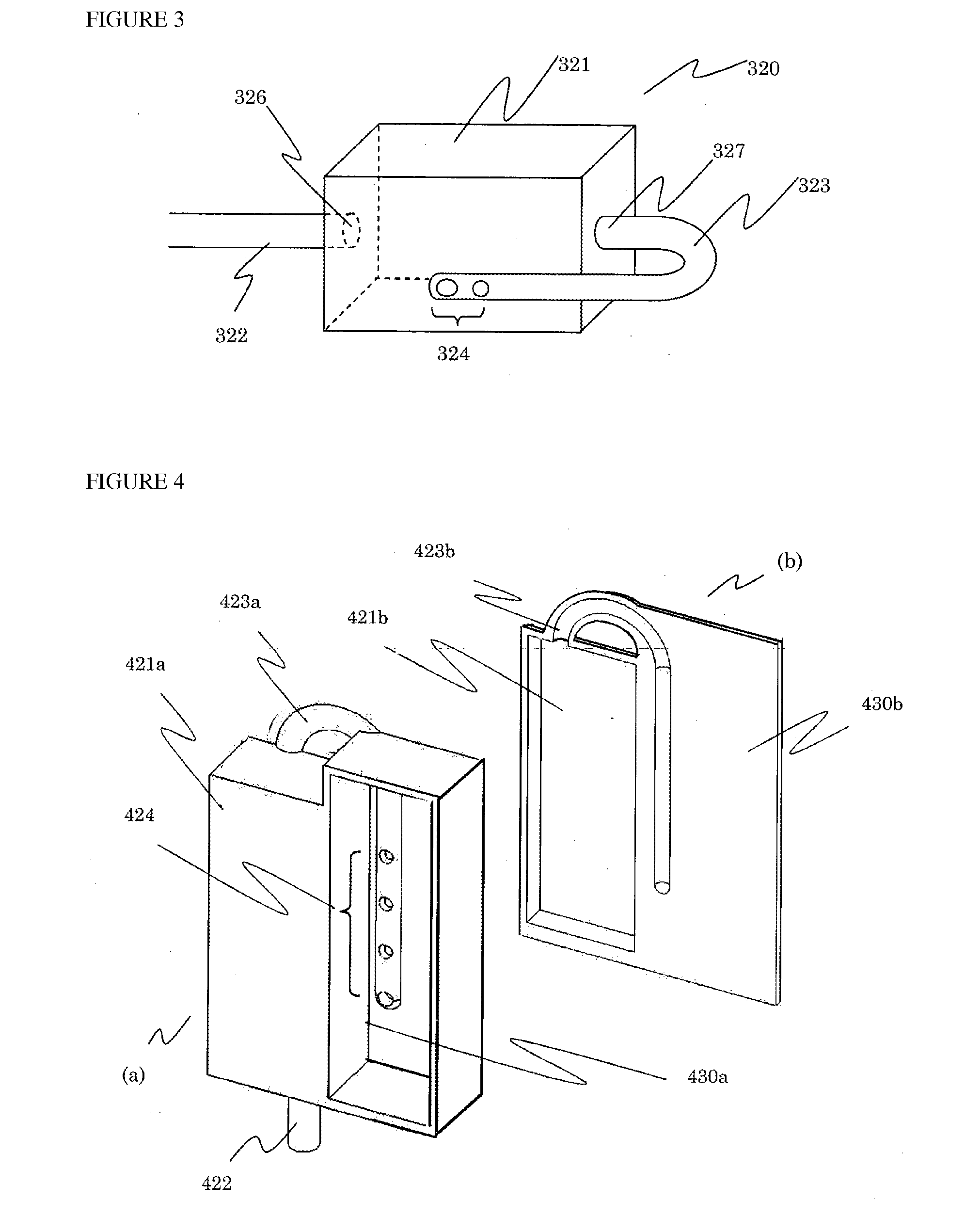

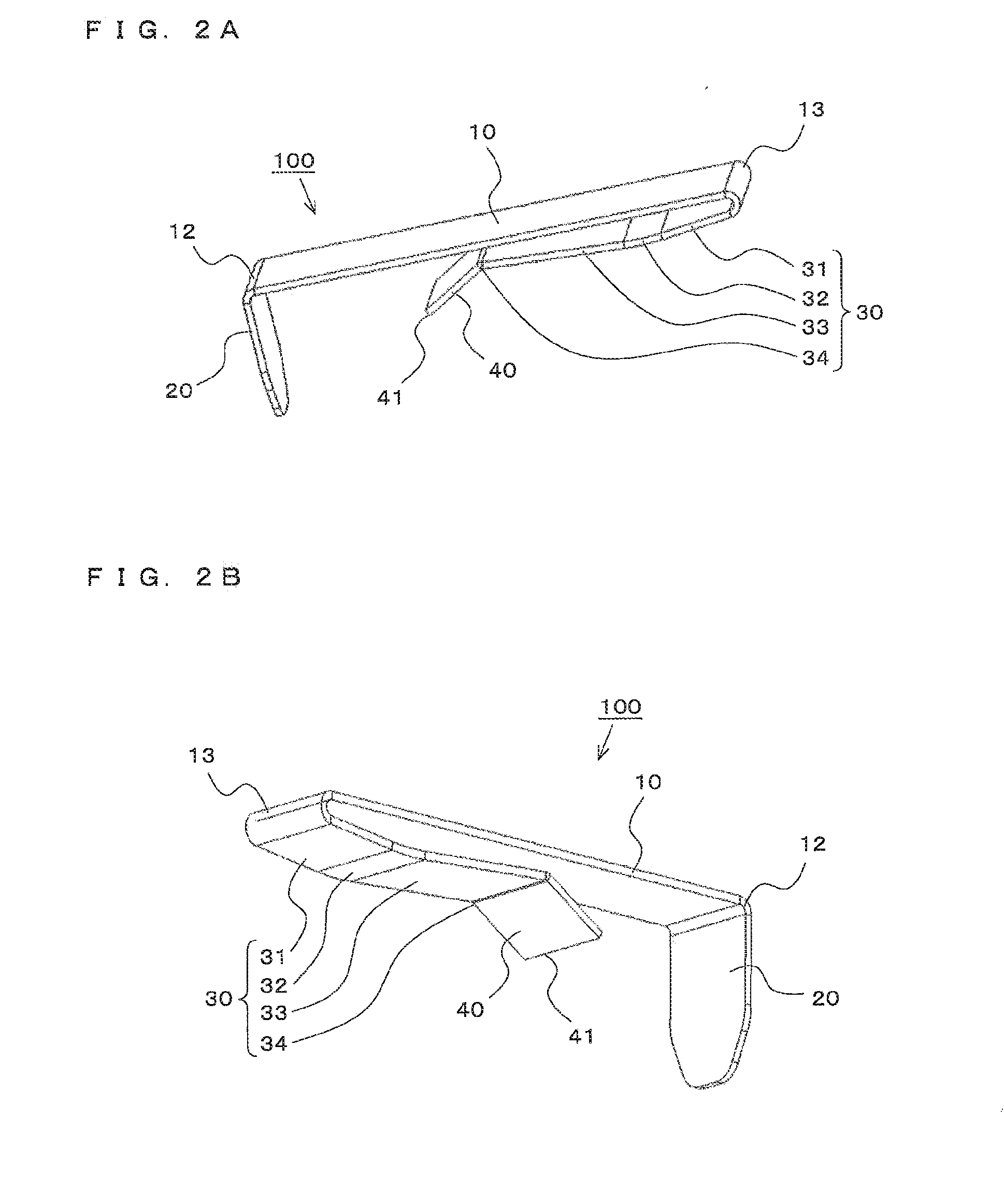

Anti-fogging and air-conditioning system for electric vehicle, dehumidifying unit, dehumidifying cassette, and dehumidifying member

InactiveUS20130183894A1Reduce electric powerImprove usabilityGas treatmentAir-treating devicesElectric vehicleAnti-fog

Provided is an anti-fog and HVAC system (30, 30A, 30B) for an electric vehicle, which is configured to dehumidify air inside the electric vehicle, the anti-fog and HVAC system including: a unit casing (1K) formed into a rectangular parallelepiped shape with a hollow interior, the unit casing (1K) containing a dehumidifying unit (1) removably storing a dehumidifying cassette (3) containing a dehumidifying member (2); an inlet duct (7) for guiding the air inside the electric vehicle to an input side of the unit casing (1K); and a ventilation duct (5) for discharging, into the electric vehicle, dehumidified air from an output side of the unit casing (1K).

Owner:WATANABE TAKUMASA

Lithium ion power battery and preparation method thereof

InactiveCN106992318ALarge specific surface areaExcellent anisotropic electrical and thermal conductivityMaterial nanotechnologyCell electrodesCarbon nanotubeLithium-ion battery

The invention discloses a lithium ion power battery comprising a positive electrode plate and a negative electrode plate, wherein the positive electrode plate comprises a positive electrode current collector and a positive electrode paste arranged on the surface of the positive electrode current collector, and the positive electrode paste is prepared from the following components by weight percent: 98.6 to 99.16% of LiNi1-X-YCoxAlyO2, 0.02 to 0.05% of single-walled carbon nanotubes, 0.02 to 0.05% of grapheme, and 0.8 to 1.3% of polyvinylidene fluoride; the negative electrode plate comprises a negative electrode current collector and a negative electrode paste arranged on the surface of the negative electrode current collector, and the negative electrode paste is prepared from the following components by weight percent: 96.3 to 97% of graphite material, 1.3 to 1.5% of sodium carboxymethyl cellulose, and 1.7 to 2.2% of styrene butadiene rubber. The invention also provides a method for preparing the battery. The lithium ion power battery has the advantages of excellent isotropic electrical and thermal conductivity, smaller size and weight, and long service life.

Owner:广西卓能新能源科技有限公司

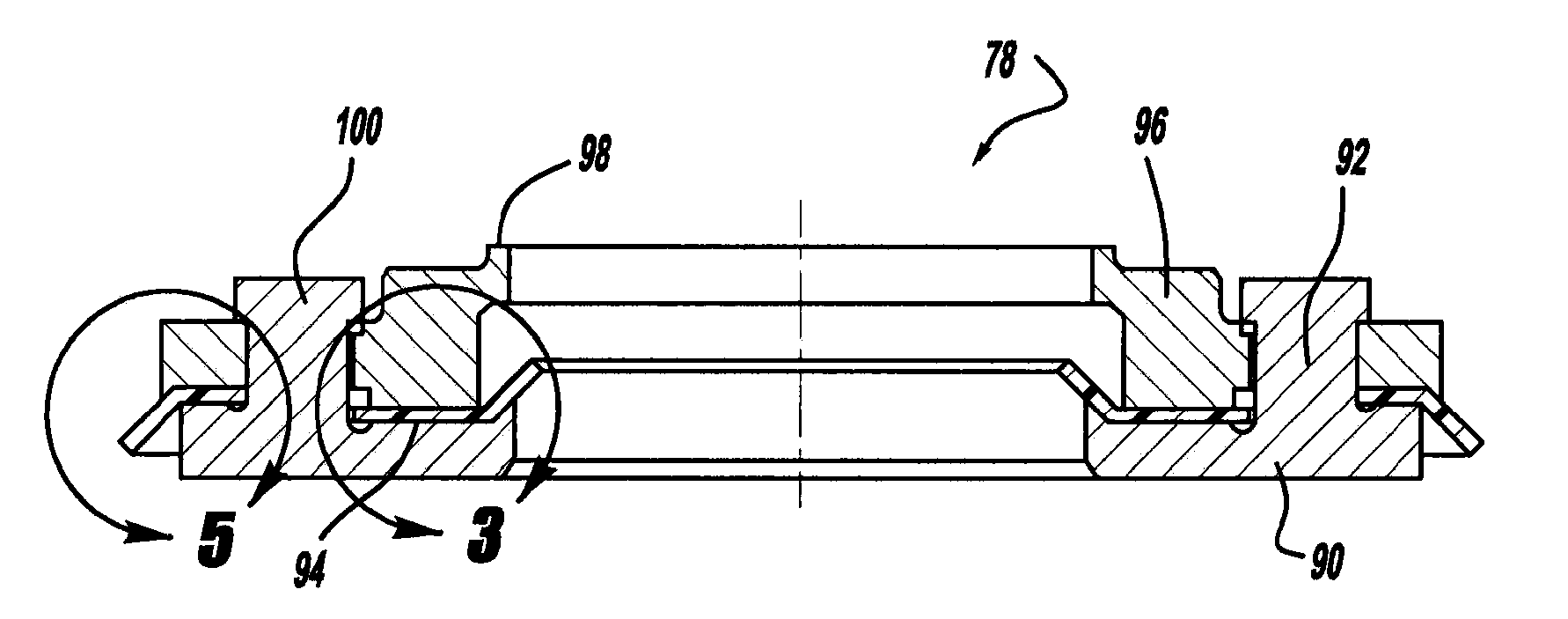

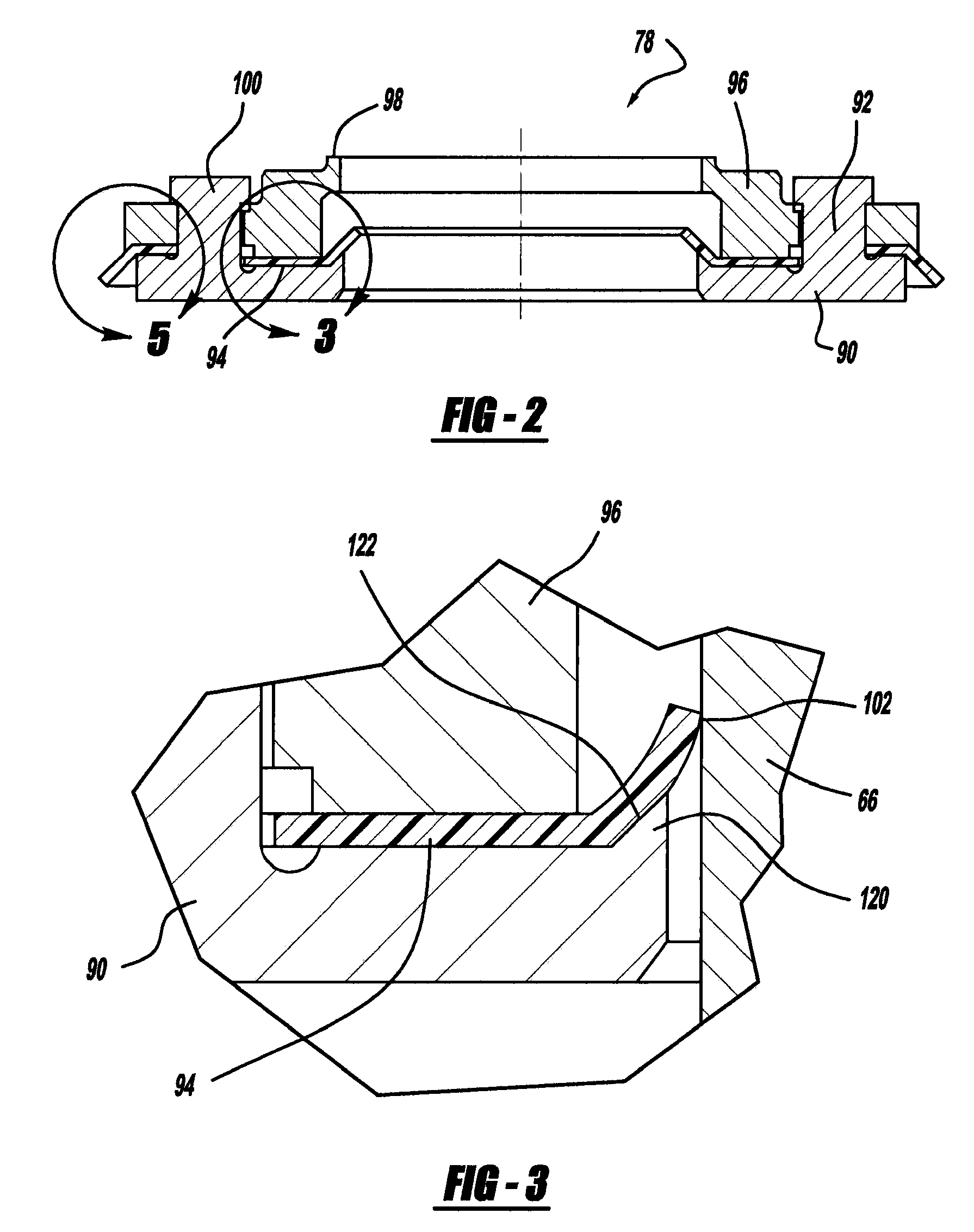

Scroll machine using floating seal with backer

InactiveUS20070224071A1Improve reliability and durabilitySlow downRotary/oscillating piston combinations for elastic fluidsEngine sealsEngineeringMechanical engineering

Owner:EMERSON CLIMATE TECH INC

Scroll machine using floating seal with backer

InactiveUS7967584B2Improve reliability and durabilitySlow downRotary/oscillating piston combinations for elastic fluidsEngine sealsEngineeringMechanical engineering

Owner:EMERSON CLIMATE TECH INC

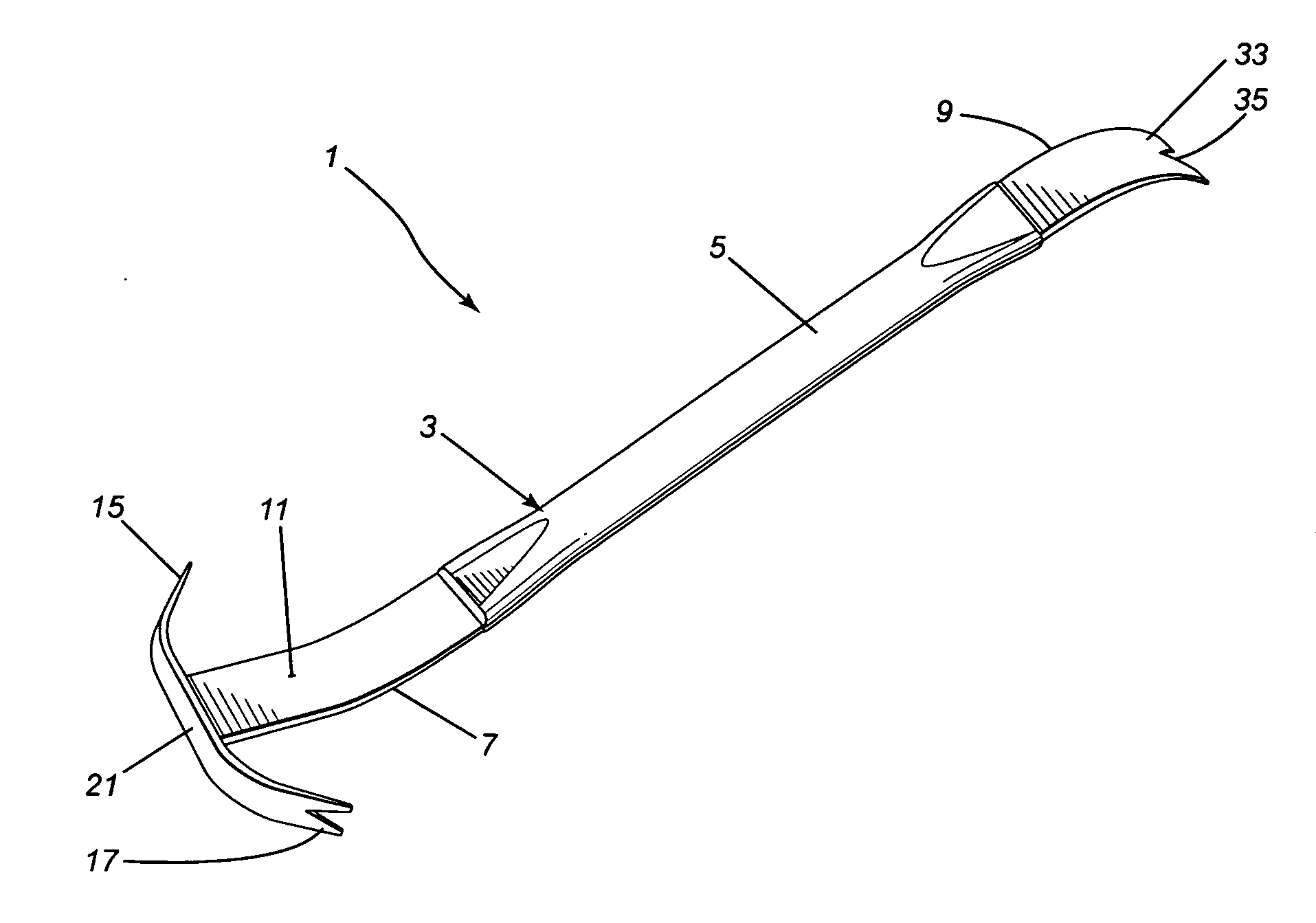

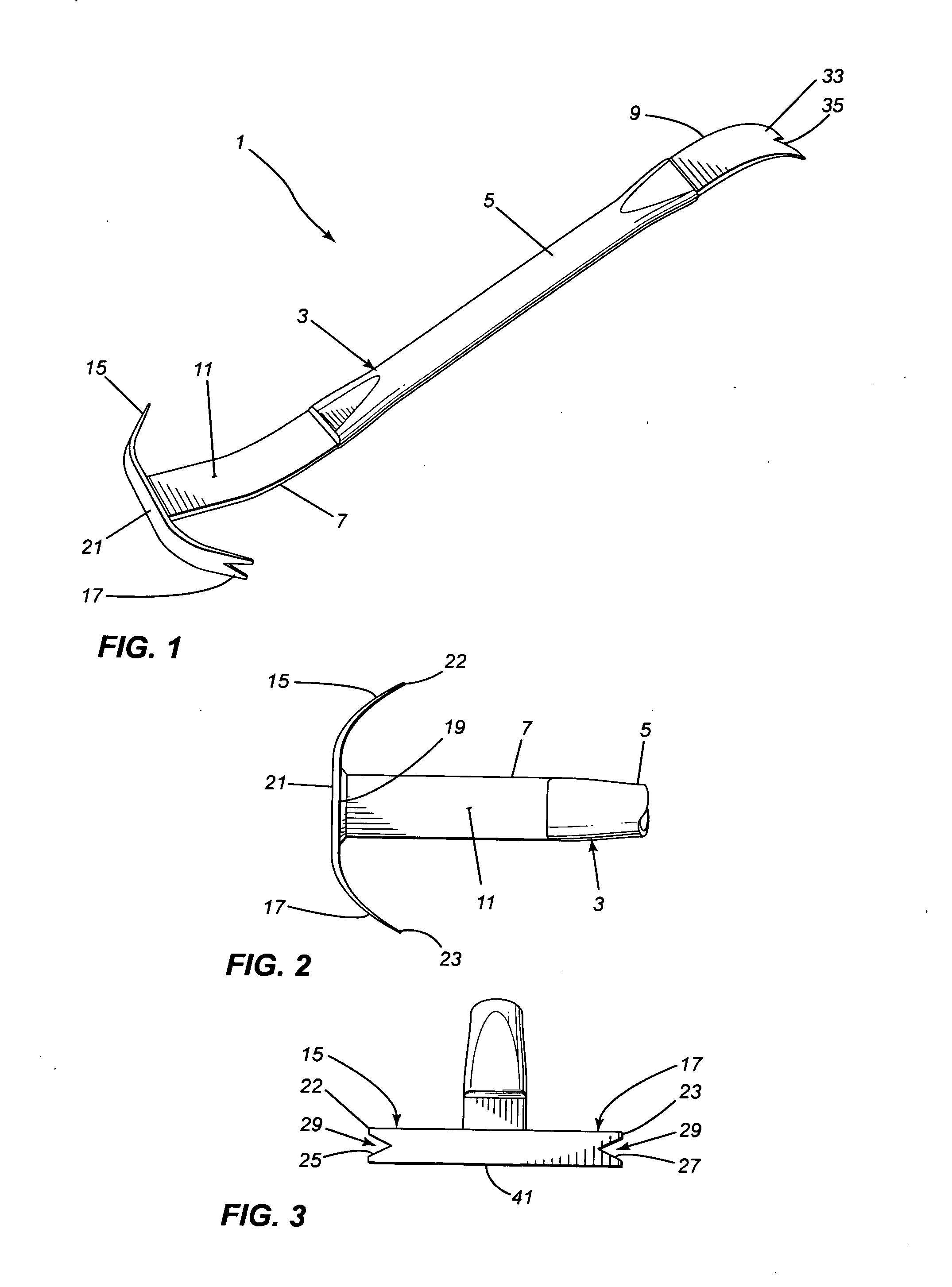

Pulling tool

InactiveUS20070252117A1Easy to disassembleEasy to use to remove articleCrowbarsNail extractorsEngineeringMechanical engineering

A pulling tool for grabbing and pulling material from underneath structural elements. The tool has a handle, the handle having a main body portion and having one flat end portion bent from one end of the body portion. A thin, narrow, claw member is attached to the free end of the one end portion and extends across and past both sides of the one end portion to form a claw on each side of the handle at one end of the handle. Each claw is tapered to a straight end edge which edge is transverse to the end portion. Each claw has a narrow v-shaped material receiving slot extending inwardly from the straight end edge to allow the claw to grab the material being removed.

Owner:HARPELL WILLIAM

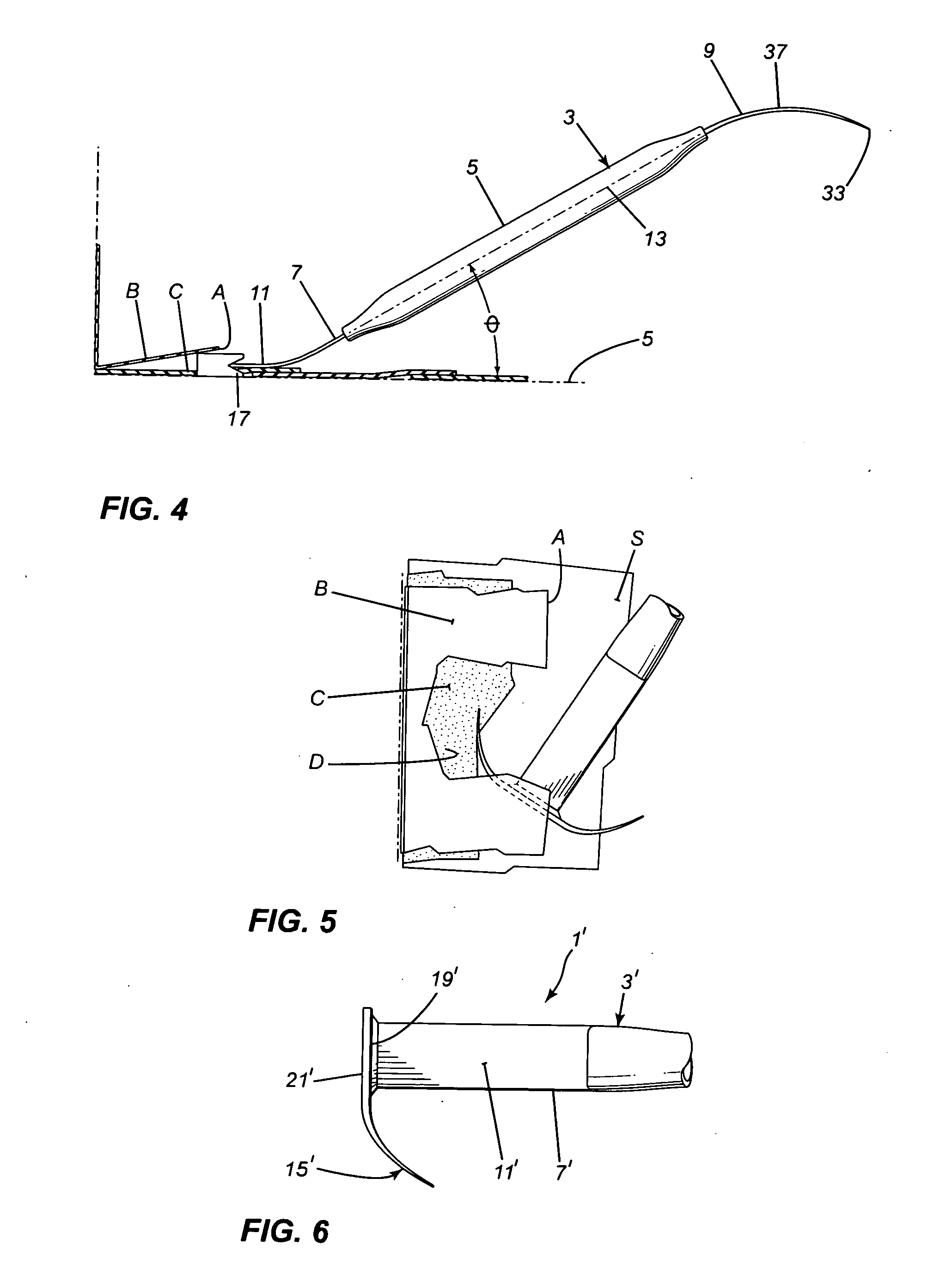

Pure-optical HDMI optical cable based on wireless transmission

InactiveCN106131516ASmall and lightweightMiniaturizationOptical transmission adaptationsRadio-over-fibreWireless transmissionHDMI

The invention relates to a pure-optical HDMI optical cable based on wireless transmission. The pure-optical HDMI optical cable comprises a high-definition multimedia transmitting module, a high-definition multimedia receiving module and an optical fibre; one end of the high-definition multimedia transmitting module is connected to a signal source; the other end of the high-definition multimedia transmitting module is connected to the high-definition multimedia receiving module through the optical fibre; a wireless transmitting module is also built in the high-definition multimedia transmitting module; the high-definition multimedia transmitting module is connected with a wireless receiving module built in the high-definition multimedia receiving module through the wireless transmitting module; an electric-optical conversion module used for converting electric signals into optical signals is also built in the high-definition multimedia transmitting module; and an optical-electric conversion module used for converting optical signals into electric signals is also built in the high-definition multimedia receiving module. The pure-optical HDMI optical cable disclosed by the invention has the characteristics of being high in transmission rate and electromagnetic interference resistant capability.

Owner:WUHAN POWERISE OPTOELECTRONICSAL TECH

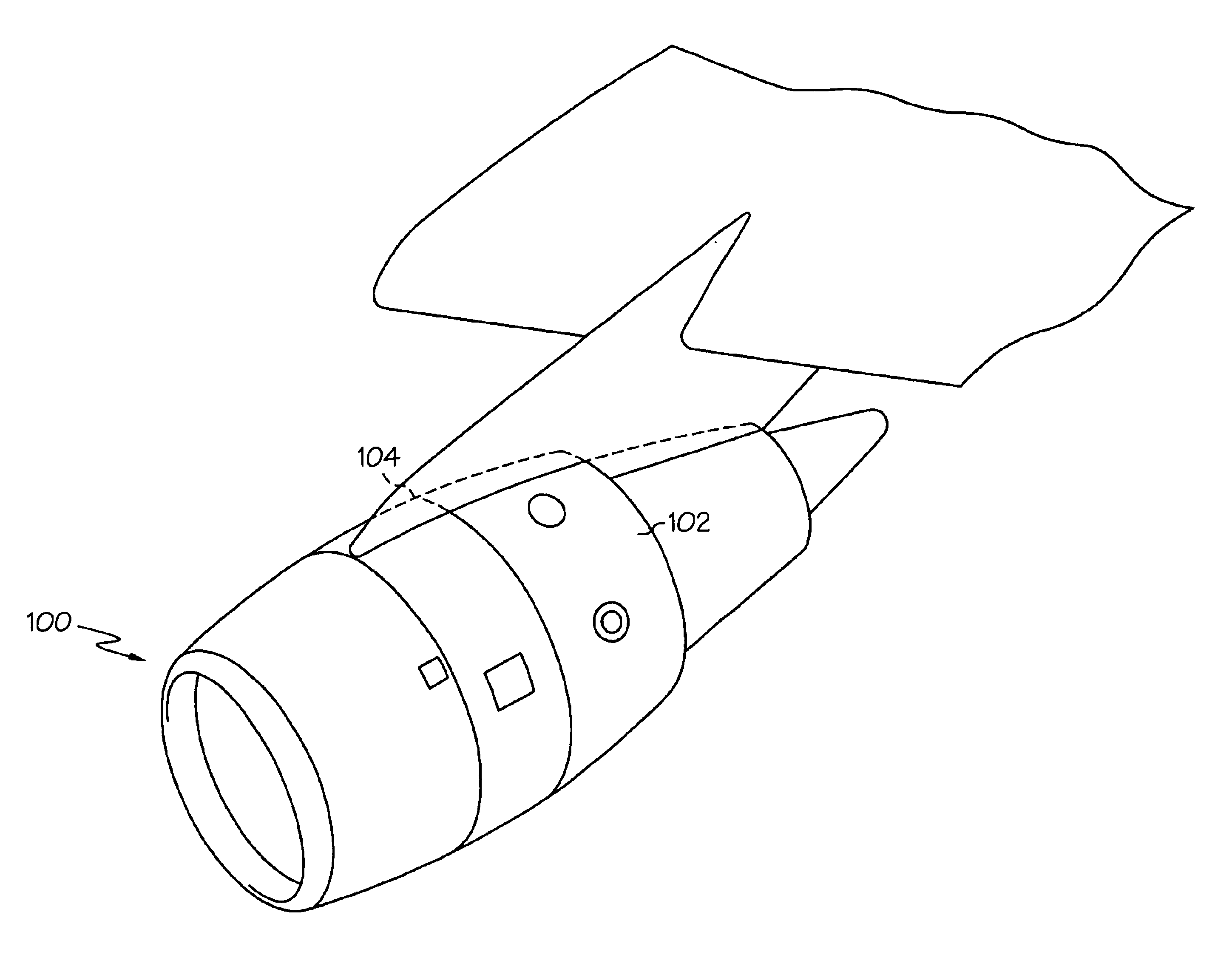

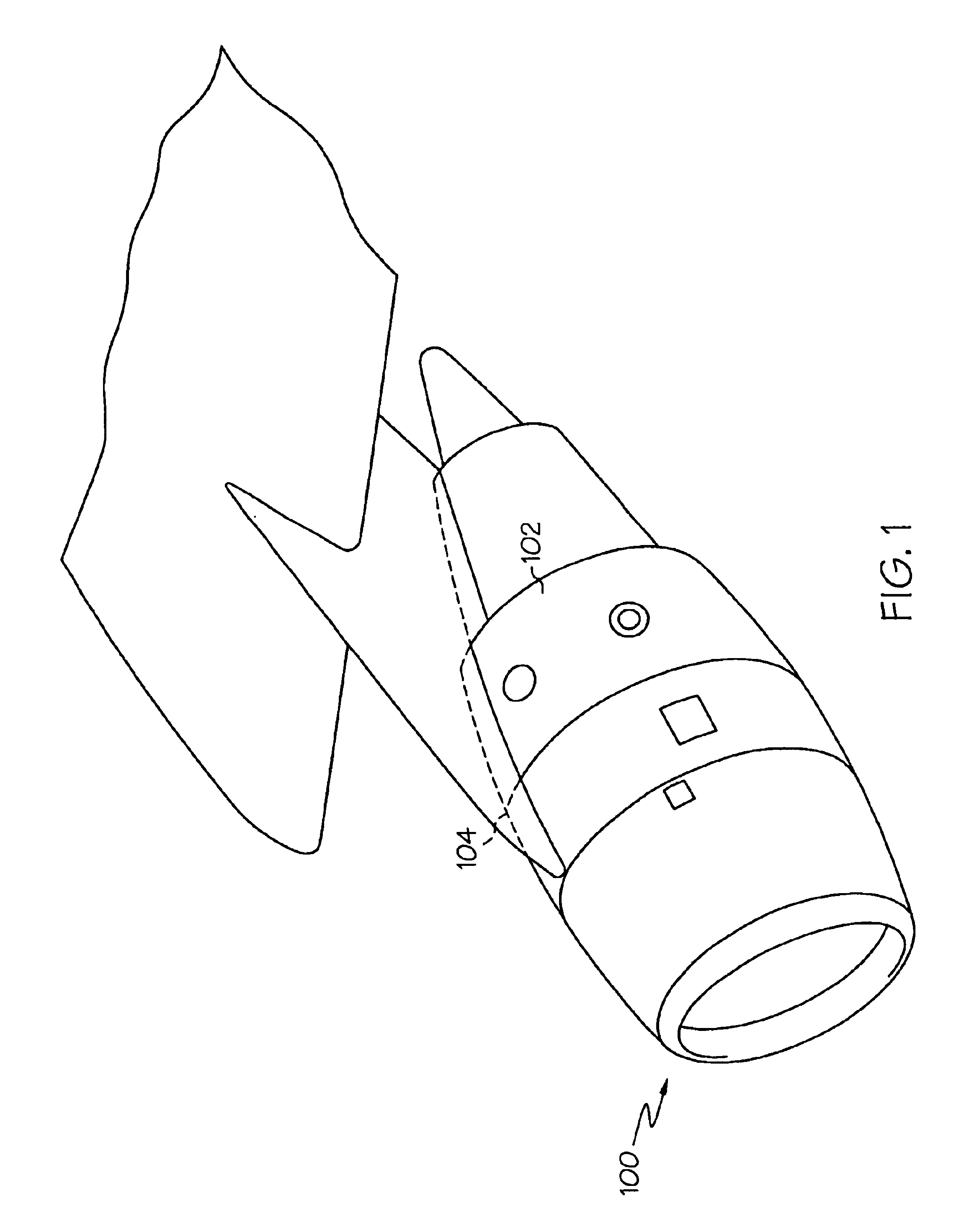

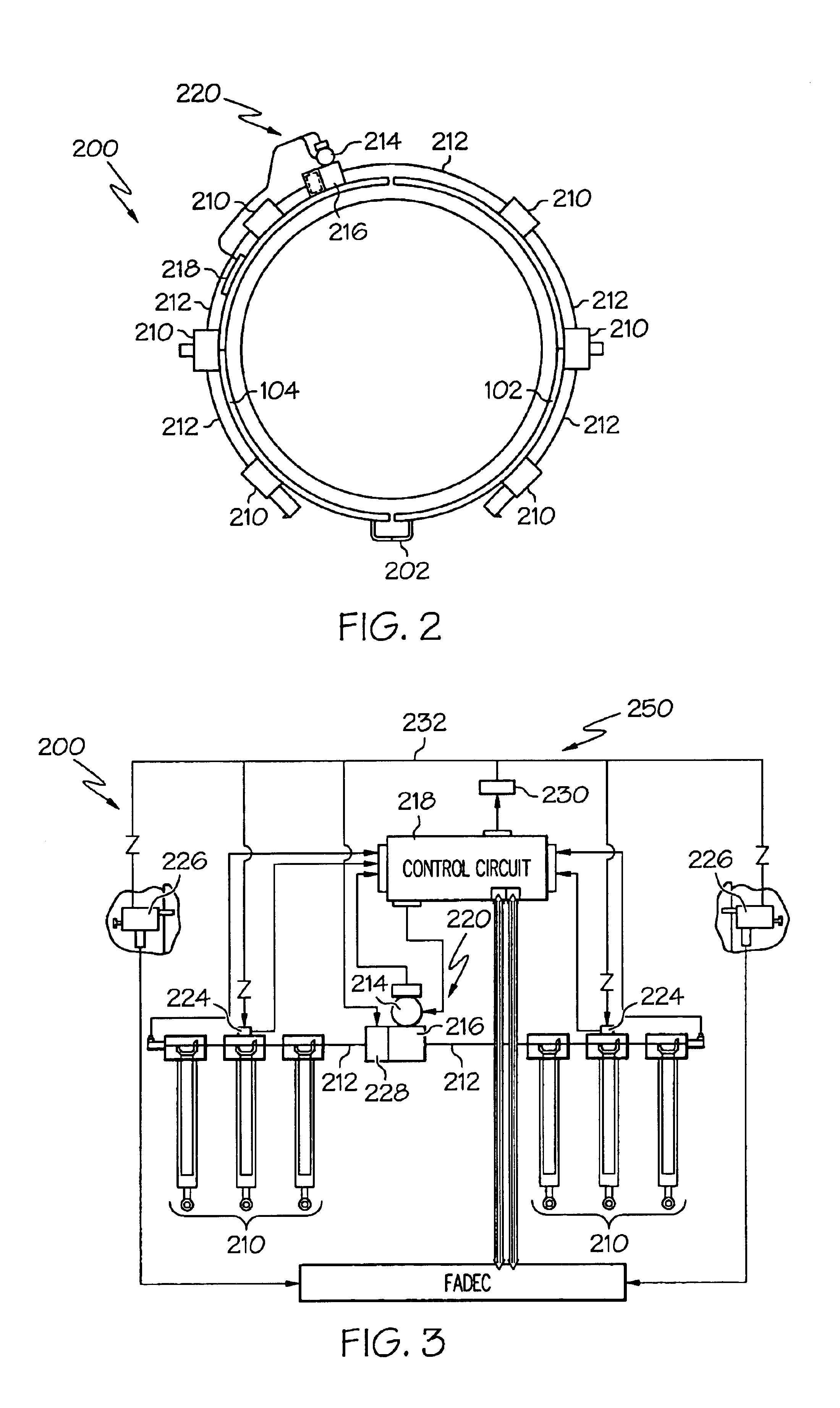

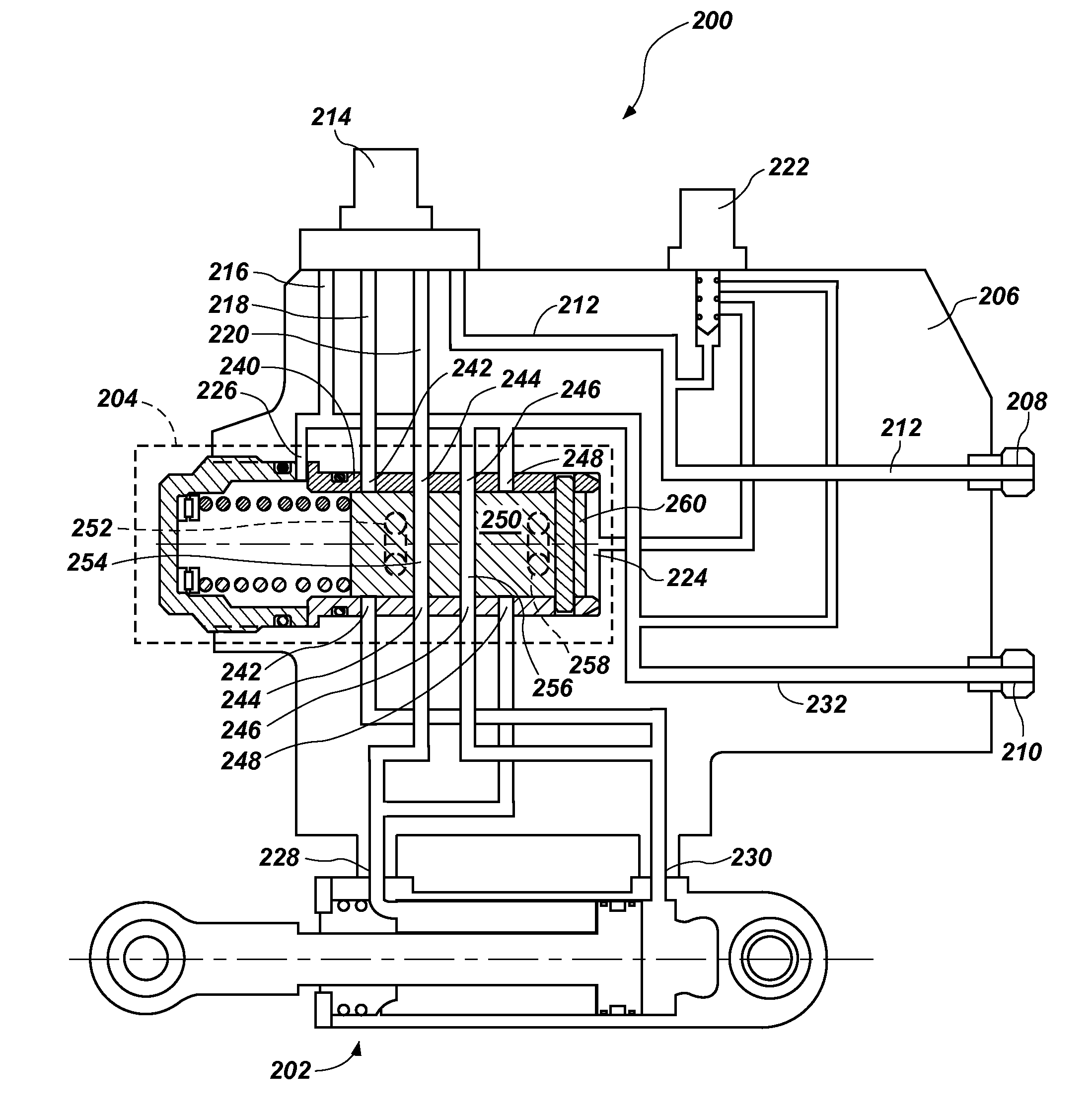

Electro-hydraulic thrust reverser lock actuation system and method

InactiveUS6848651B2Small and lightweightEngine fuctionsEfficient propulsion technologiesControl signalElectro hydraulic

An electro-hydraulic thrust reverser lock actuation system includes a hydraulic fluid source and a lock actuator assembly that is configured to selectively pressurize the hydraulic fluid. The lock actuator assembly is adapted to receive a lock control signal and, in response, pressurize the hydraulic fluid in the hydraulic fluid source. One or more lock assemblies are in fluid communication with the hydraulic fluid source and are configured, in response to the hydraulic fluid pressurization, to move to one of a locked or an unlocked position.

Owner:HONEYWELL INT INC

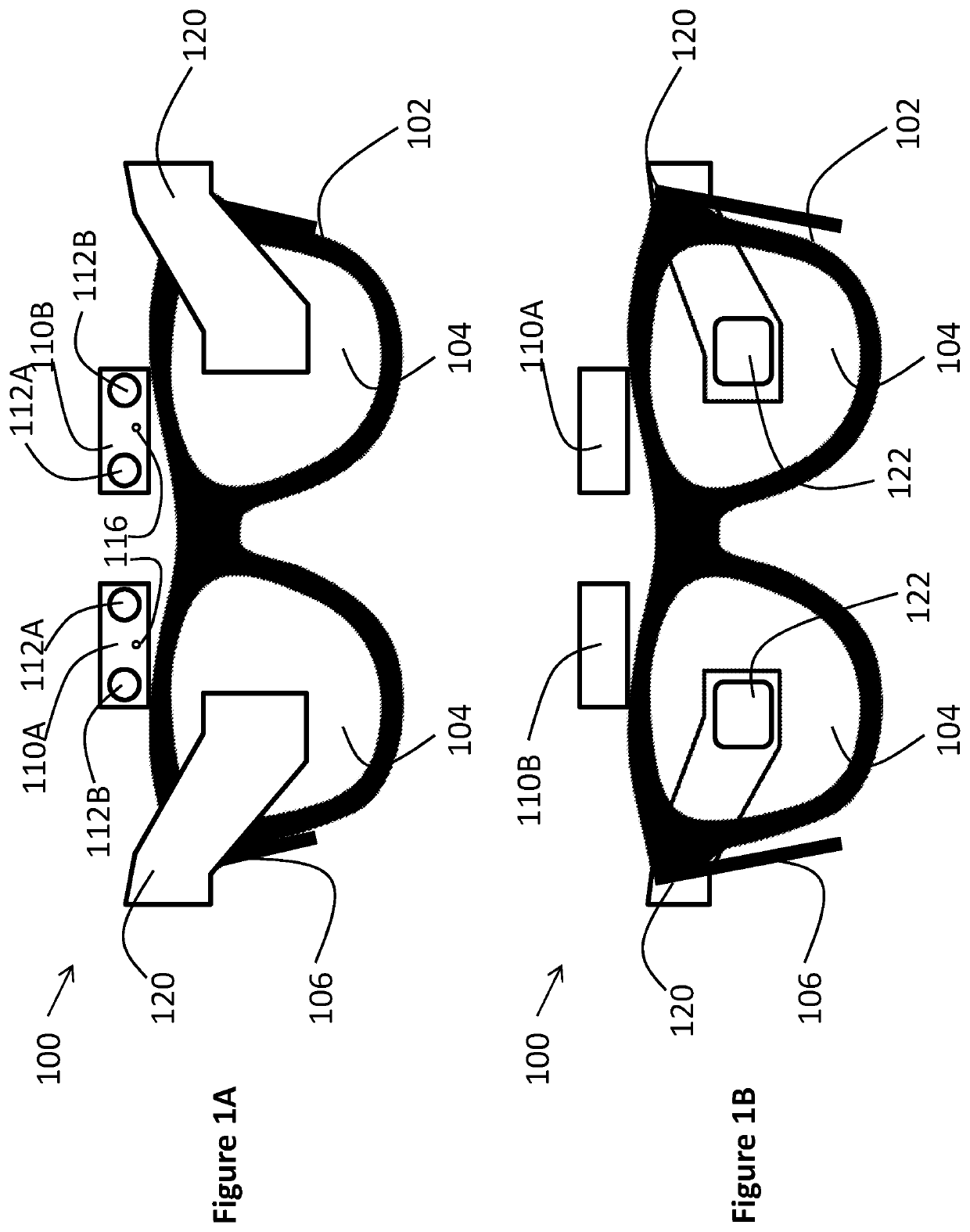

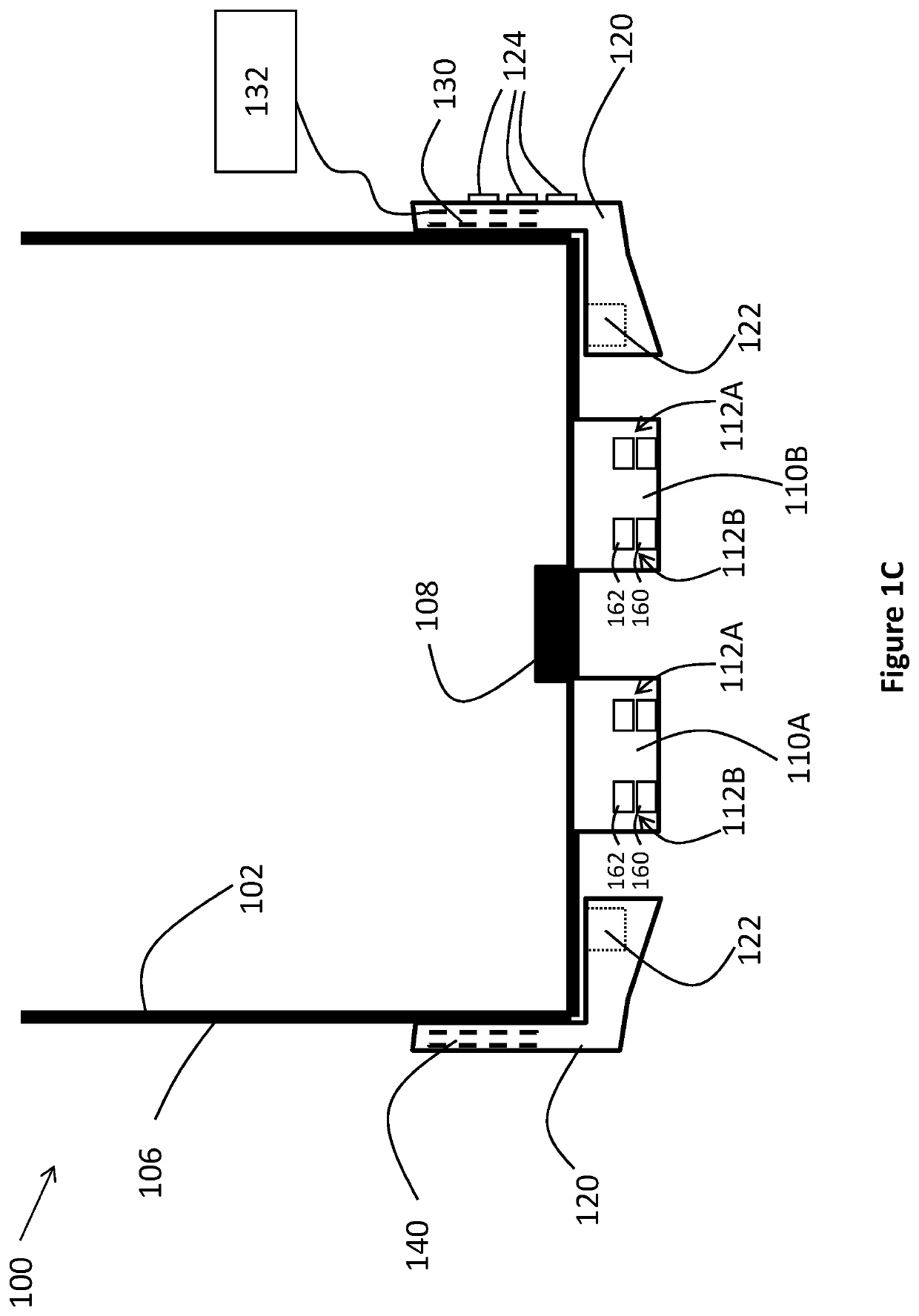

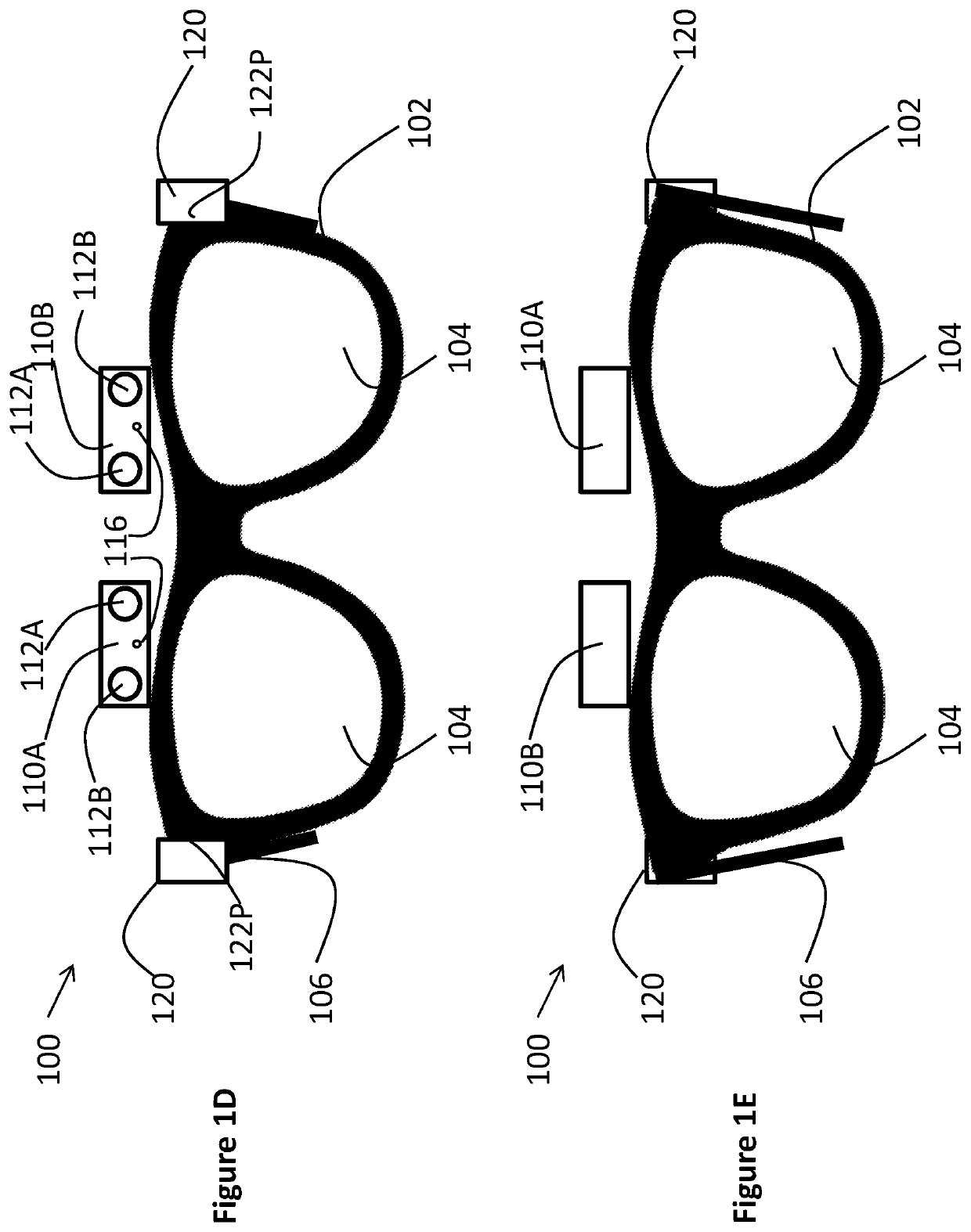

Magnification glasses with multiple cameras

ActiveUS10877262B1Low implementation costSmall and lightweightSomatoscopeRadiation diagnostics for dentistryOphthalmologyMagnifying glass

Magnification glasses and methods of use, the glasses including a first camera array for capturing a magnified image in the field of view of the glasses, the first camera array including a first camera and a second camera, where the first camera and the second camera provide different levels of magnification, where the first camera and the second camera have the same working distance of between 150 mm to 400 mm, and where the first camera and the second camera are fixed focus cameras.

Owner:LUXEMBOURG ITZHAK

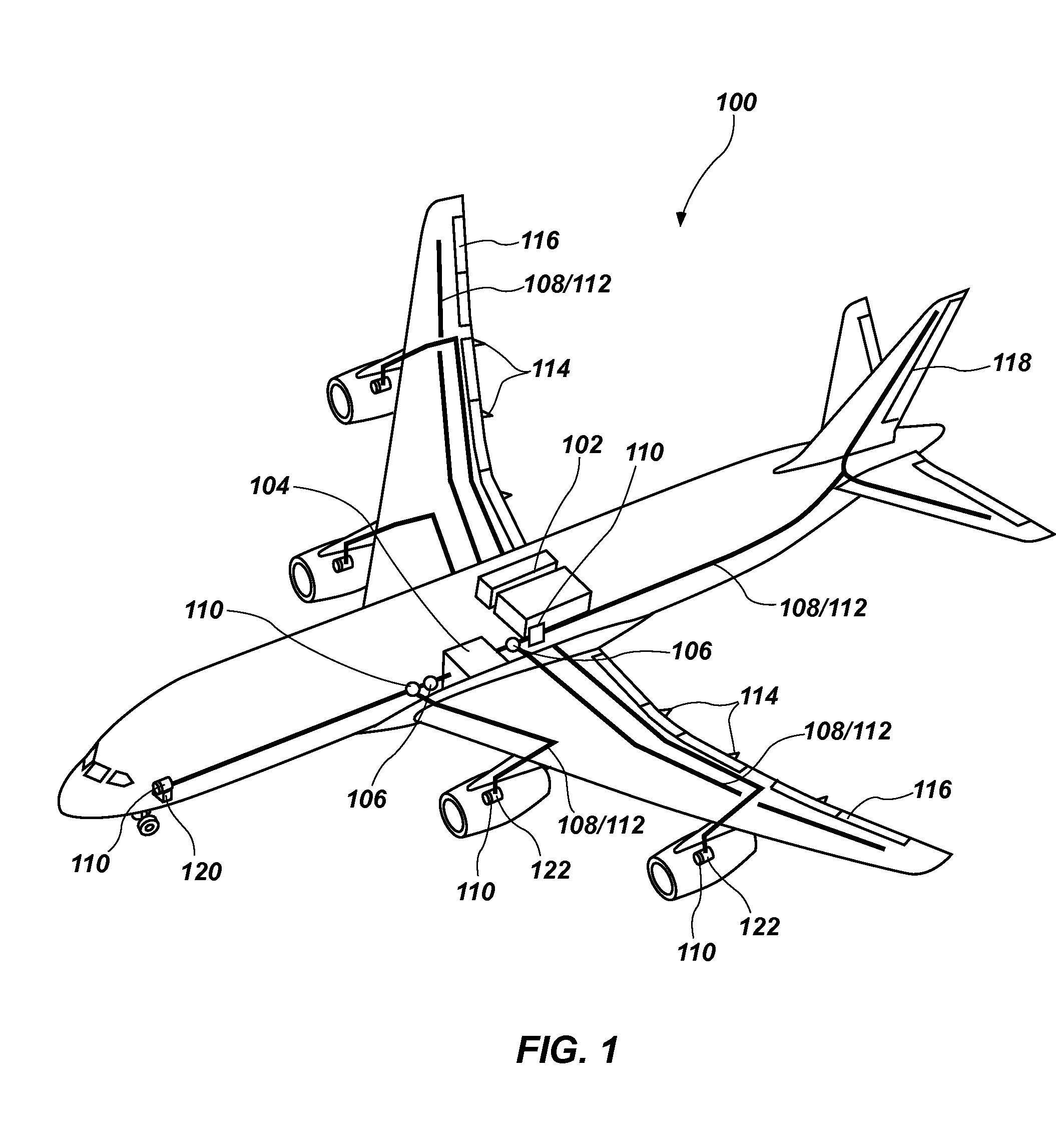

Hydraulic valve with helical actuator

ActiveUS20150027547A1Small and lightweightSimple and robust in operationOperating means/releasing devices for valvesServomotor componentsSpool valveEngineering

A hydraulic spool valve includes a housing, a valve element disposed within the housing, a first piston coupled to the valve element, and a first biasing member. The housing includes a pair of first ports. The valve element is selectively moveable within the housing between a first closed position and a second open position allowing fluid communication between the first ports. Hydraulic pressure against the first piston causes helical translation of the piston in a first direction, and motion of the valve element in a first direction from the first position toward the second position. The first biasing member is configured to bias the first piston and the valve element toward the first position.

Owner:THE BOEING CO

Modular robot welding tongs

ActiveCN103949758ACompact structureFlexible operationElectrode supporting devicesFixed frameTransformer

The invention belongs to the technical field of processing and welding and particularly discloses a pair of modular robot welding tongs. The pair of modular robot welding tongs comprises a fixed frame, a robot connecting flange, a transformer, an air cylinder, an upper tong arm and a lower tong arm. The modular robot welding tongs have the following advantages that 1) the structure is compact, the maintenance is convenient, the operation is flexible, the volume is small, the weight is light, the control is easy, the welding precision is high, the welding efficiency and the welding quality are improved, and the welding work process is safe and reliable; 2) compared with a traditional welding tong structure, the problems of wrong welding and welding leakage are solved, and the stability of a welding work state is ensured; meanwhile, the modular robot welding tongs have the advantages of low production cost, convenience in installation and easiness in popularization.

Owner:FOSHAN LONGSHEN ROBOT

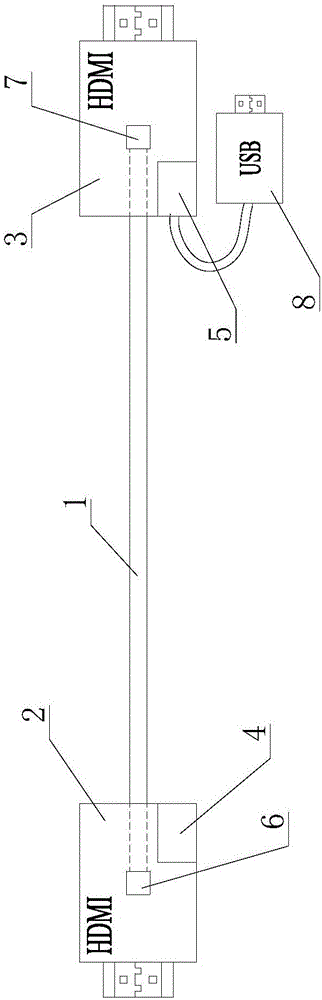

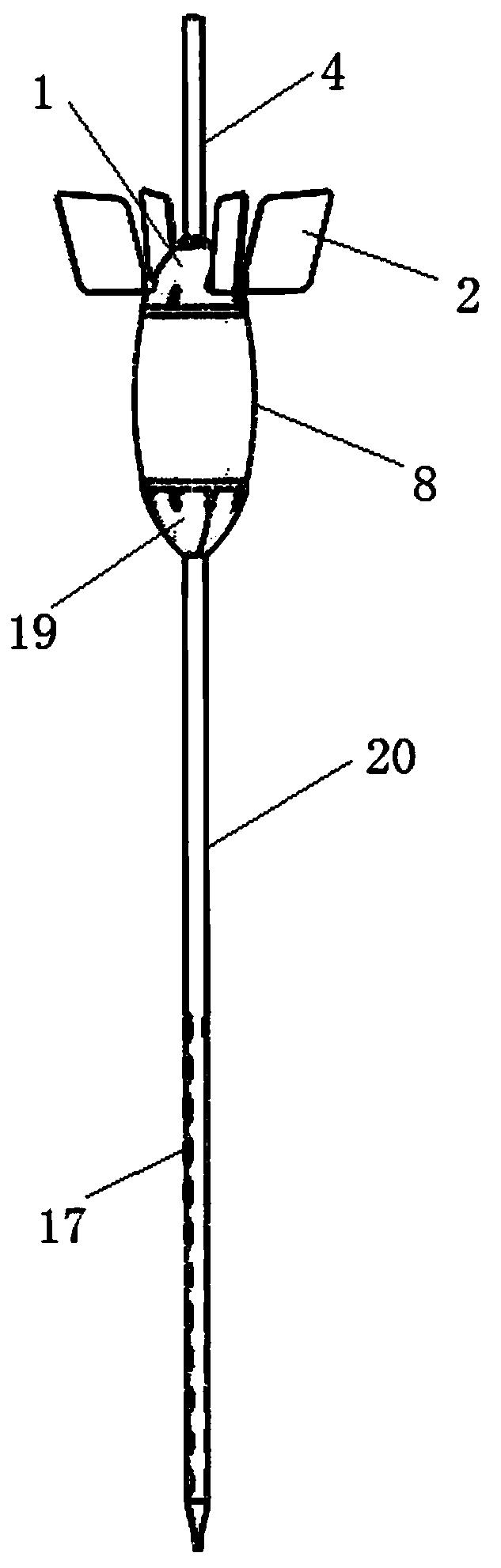

Empennage-adjustable bottom sediment temperature detection device

PendingCN109990913AGuarantee authenticity and validitySmall and lightweightThermometer detailsThermometers using electric/magnetic elementsSeabed sedimentDeep level

The invention discloses an empennage-adjustable bottom sediment temperature detection device, which comprises an empennage section, a control section and a probe section, wherein the empennage sectioncomprises an upper end cover, an empennage located outside the upper end cover, an empennage motor located inside the upper end cover to control the motion of the empennage, and an upper communication cable extending out of the top of the upper end cover; the control section comprises a sealed cabin and a floating body located outside the sealed cabin; a control mainboard, a motor driving plate,a communication mainboard and a battery pack are arranged inside the sealed cabin; the probe section comprises a lower end cover, a probe extending out of the lower end cover, and a lower communication cable located inside the probe; and the upper and lower ends of the sealed cabin are respectively connected with the upper end cover and the lower end cover. The temperature detection device disclosed by the invention can effectively correct a sinking posture of the probe by controlling the empennage, and can calculate a pouring point position and motion parameters of the whole pouring process to more effectively measure a deeper geothermal temperature gradient in a seabed.

Owner:SHANDONG PROVINCE OCEANOGRAPHIC INSTR TECH CENT +1

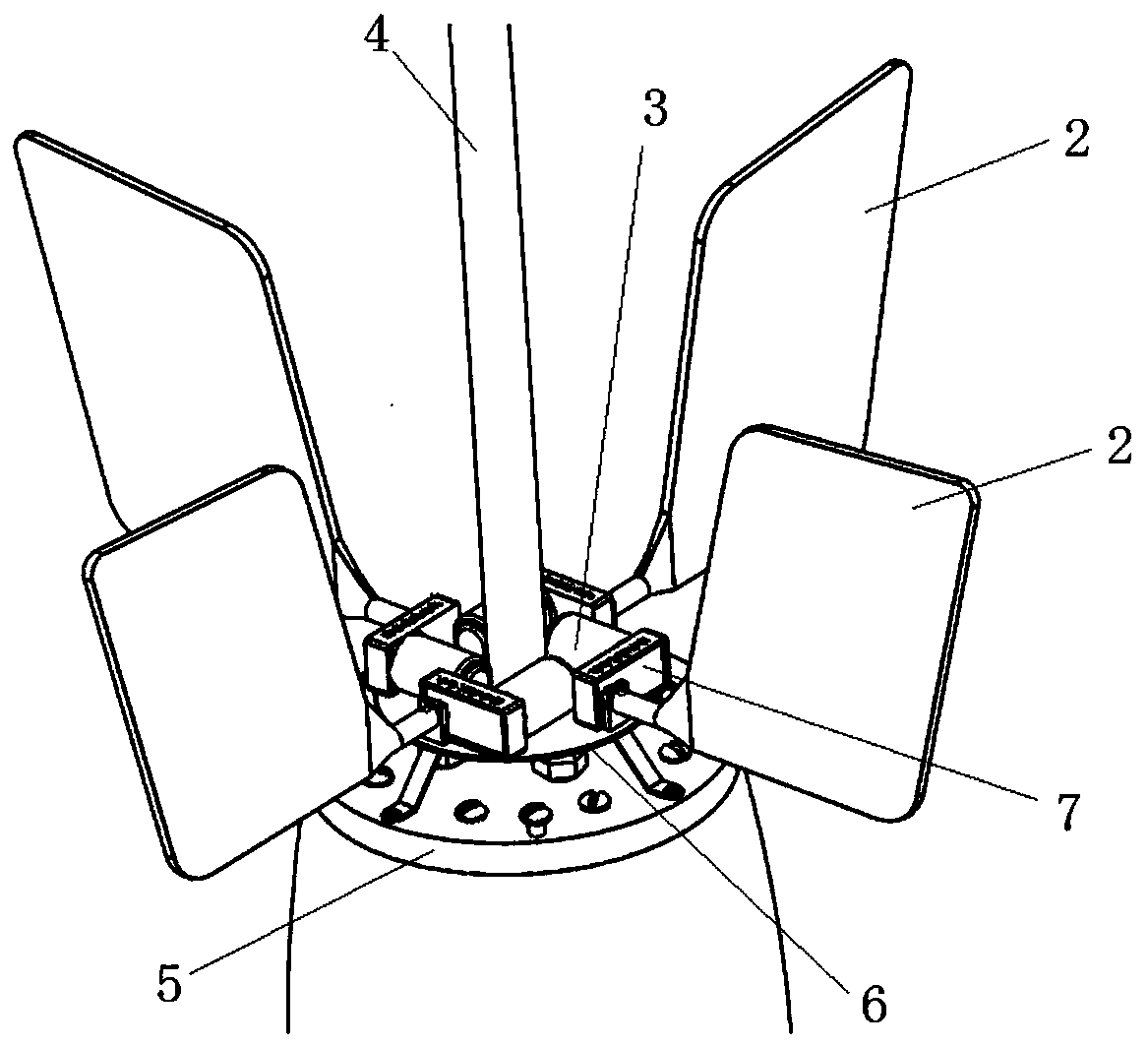

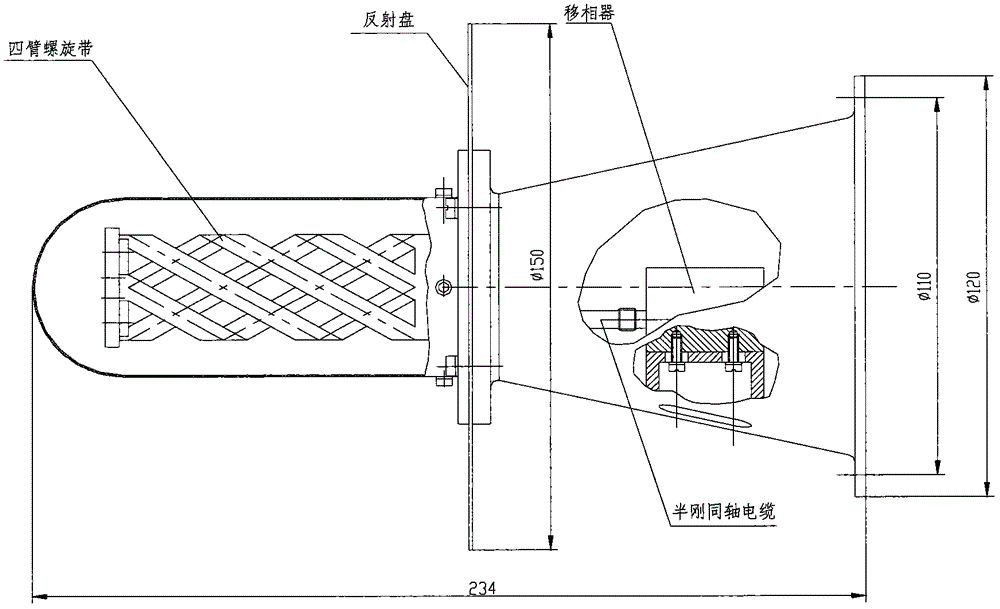

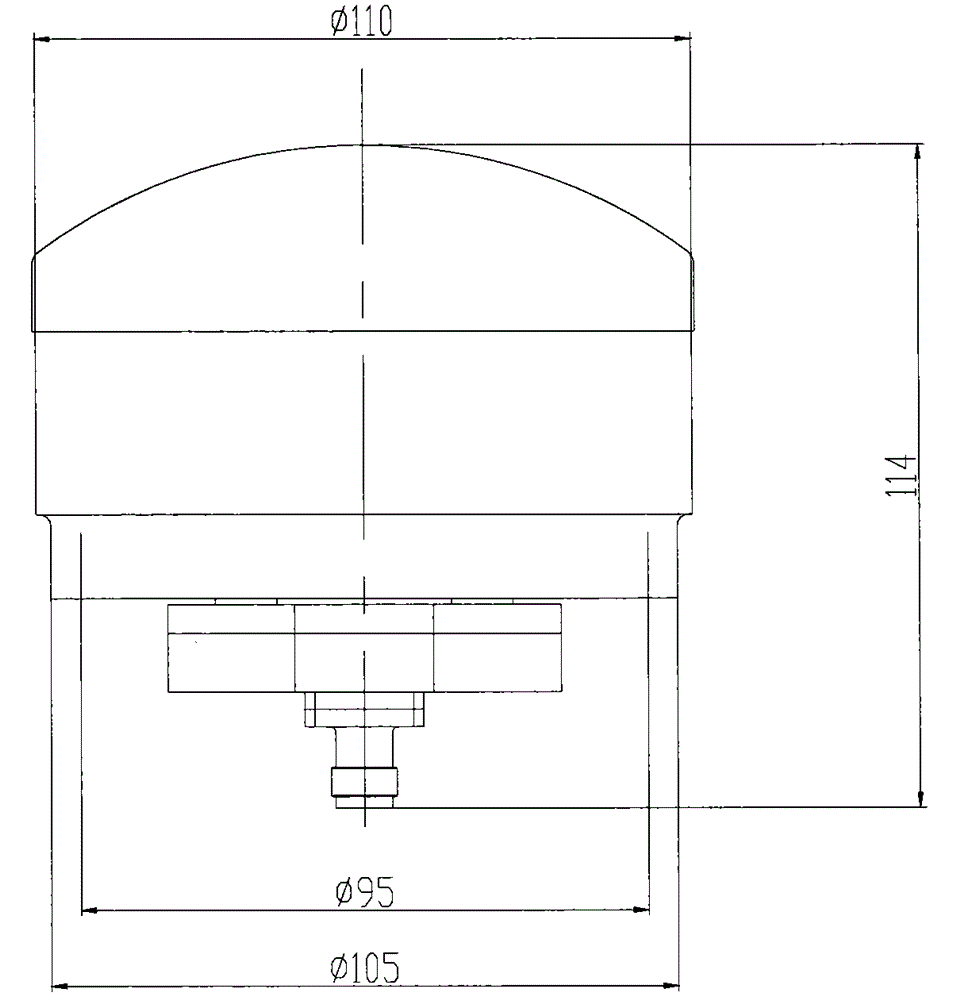

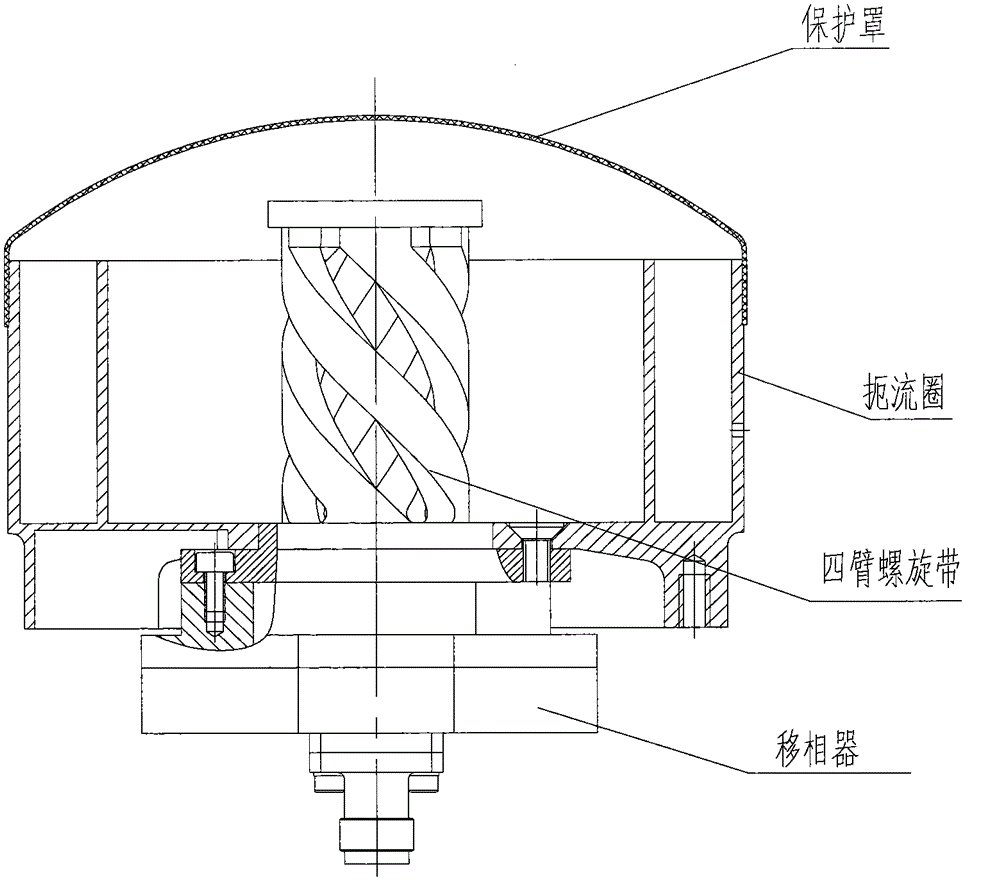

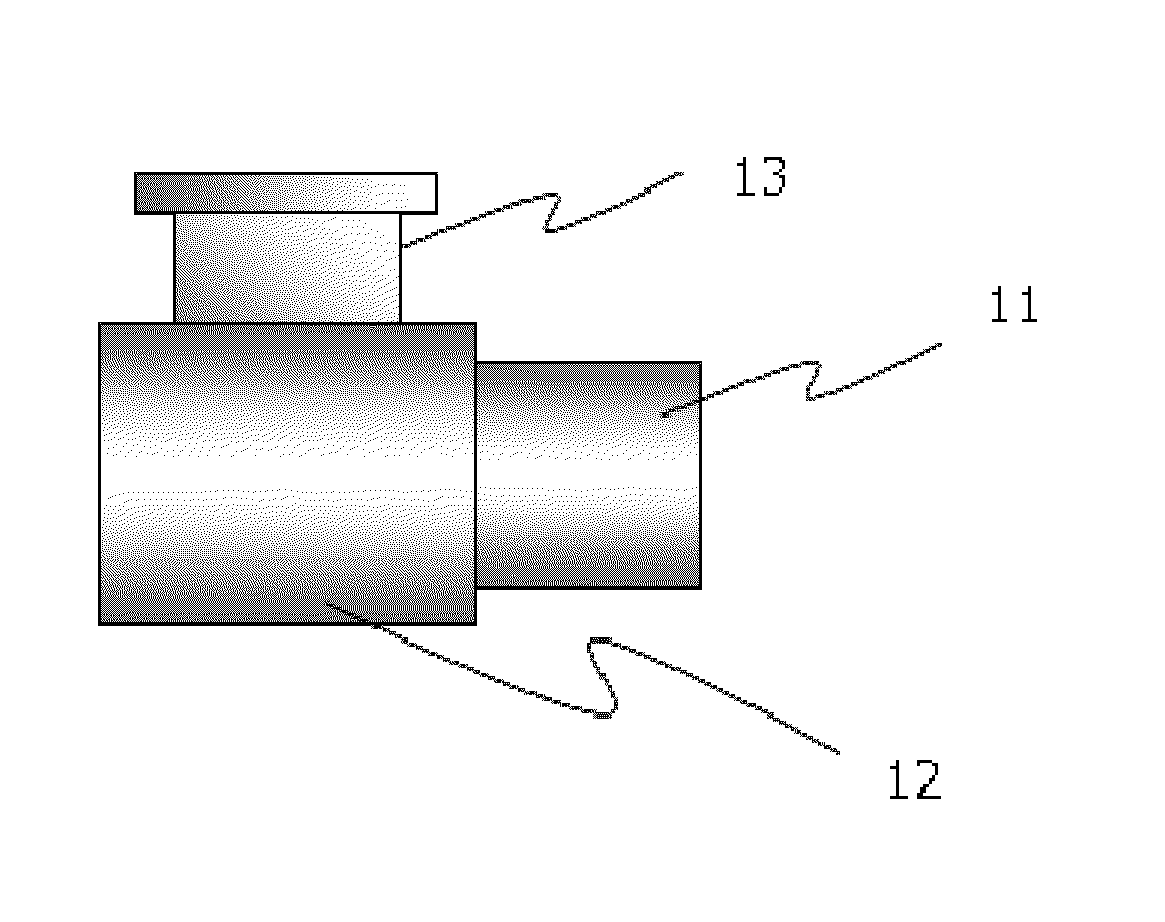

Satellite-borne S-band measurement and control antenna

InactiveCN105896075AWith hemispherical beamWith wide angle circular polarizationAntenna arraysLoop antennasMetal stripsPhase shifted

The invention provides a satellite-borne S-band measurement and control antenna, which comprises a choking coil, a protection cover, four-arm spiral band and a phase shifter, and is characterized in that the choking coil is integrally machined, and the overall dimensions and the number of turns of the choking coil can be adaptively changed according to different electrical indicator requirements; the protection cover is molded by a composite material and is effectively adhered to the choking coil so as to form a compact structure; the four-arm spiral band is of a pure metal structure and divided into an inner cylinder and an outer cylinder; phase shifter does not contain a component inside and realizes phase shifting through a metal strip line; and the four-arm spiral band and the phase shifter are designed into a modular assembly and assembled according to different antenna turning direction requirements. Therefore, the antenna provided by the invention has the characteristics of miniaturization, hemispherical beam, wide-angle circular polarization, broadband and the like, the phase shifter of the antenna does not contain components, and the phase shifter and the four-arm spiral band realize radio frequency connection through structural plugging, so that the satellite-borne S-band measurement and control antenna realizes compact structure, miniaturization, light weight and high reliability.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Compressor

ActiveUS20150204318A1Maintain muffling performanceSmall and lightweightRespiratorsPositive displacement pump componentsEngineeringSmall hole

Provided is a compressor as a device which can solve a contradictory technical problem of installing an intake sound muffler while downsizing the device under a circumstance that installation of the intake sound muffler is indispensable to reduce intake noise of the compressor, and the compressor comprises: a first lid part provided with a small hole which forms an intake port of the compressor, the lid part constituting a portion of a cylindrical casing of the compressor; a cylindrical part; and a second lid part which forms a small chamber together with the first lid part, wherein the second lid part is provided with a suction nozzle for sucking air into the small chamber.

Owner:TEIJIN LTD

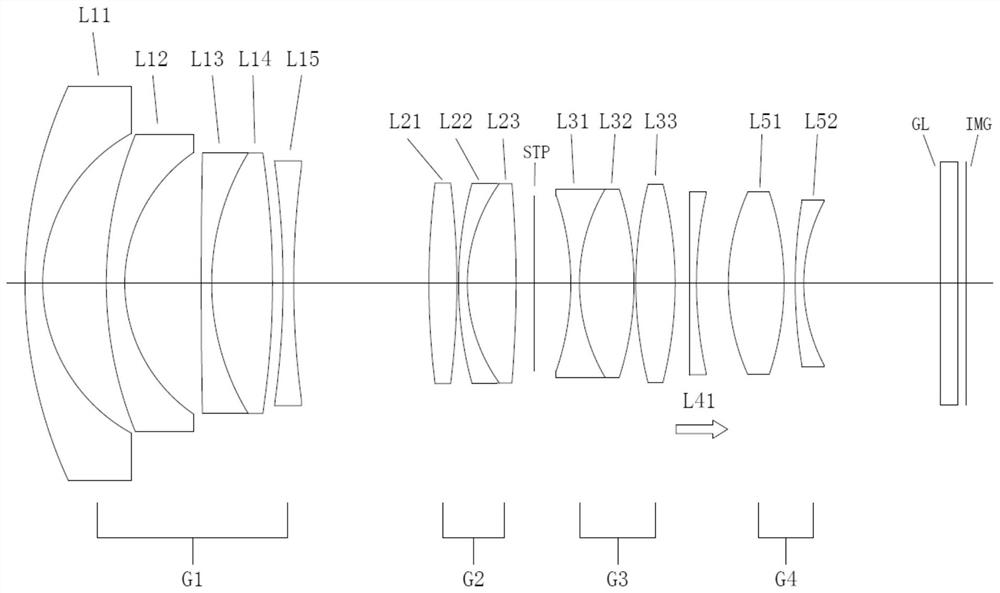

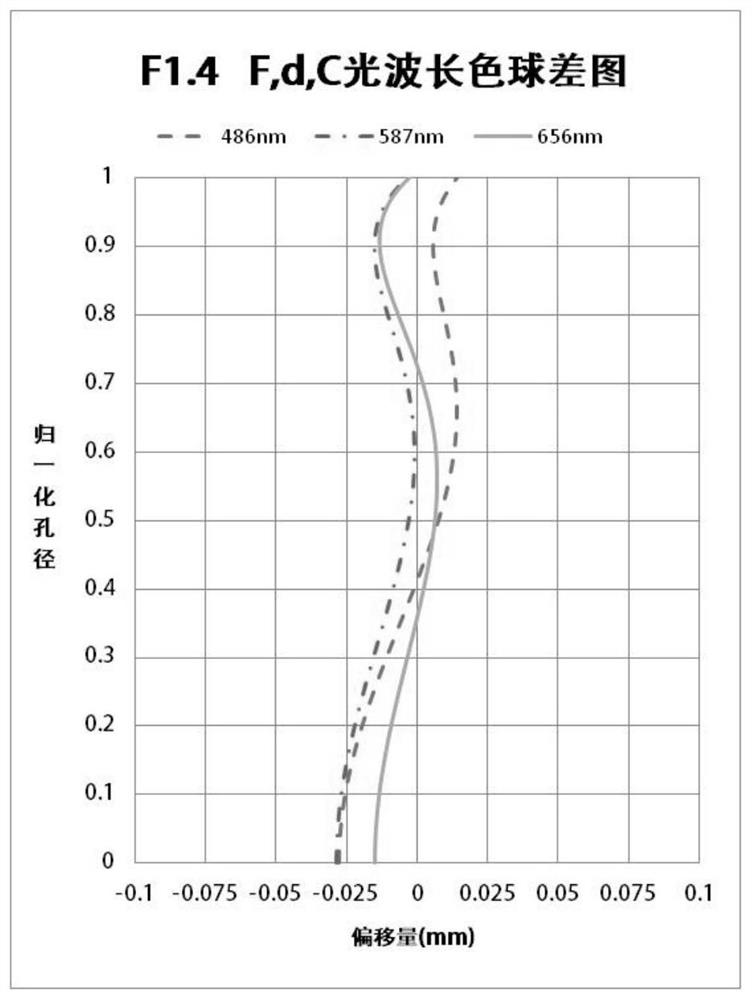

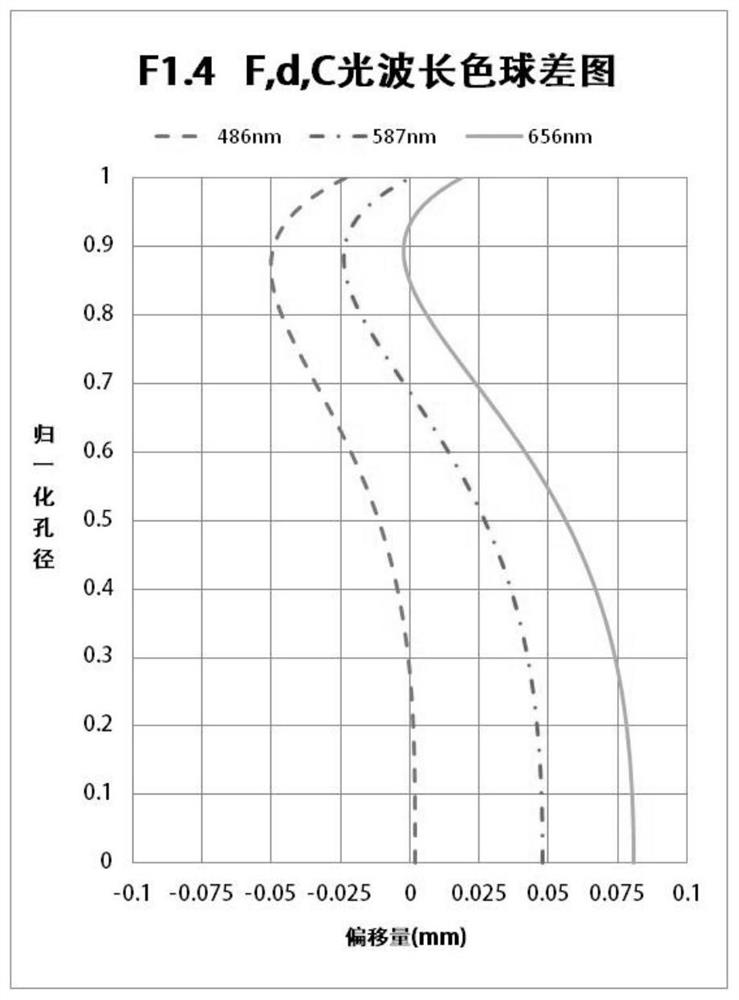

Ultra-wide-angle optical imaging system and optical equipment

The invention provides an ultra-wide-angle optical imaging system and optical equipment. The ultra-wide-angle optical imaging system sequentially comprises a first lens group with negative focal power, a second lens group with positive focal power, an aperture diaphragm, a third lens group with positive focal power, a twelfth lens with negative focal power and a fourth lens group with positive focal power from an object side to an image side, in the focusing process, the twelfth lens moves towards the image side along the optical axis, and the positions of the first lens group, the second lensgroup, the third lens group and the fourth lens group relative to the image plane remain unchanged. The first lens group satisfies the following conditional expressions: -2.8 < = F1 / F < = 1.3, (1); the second lens group satisfies the following conditional expressions: 1.8 < = F2 / F < = 2.6, (2). The invention further provides optical equipment provided with the ultra-wide-angle optical imaging system. The focusing assembly of the imaging system is composed of only one lens, so that the weight of the focusing assembly and the total weight of the optical imaging system are reduced, and meanwhile, quick focusing of the optical imaging system and imaging equipment is facilitated.

Owner:深圳市雷影光电科技有限公司

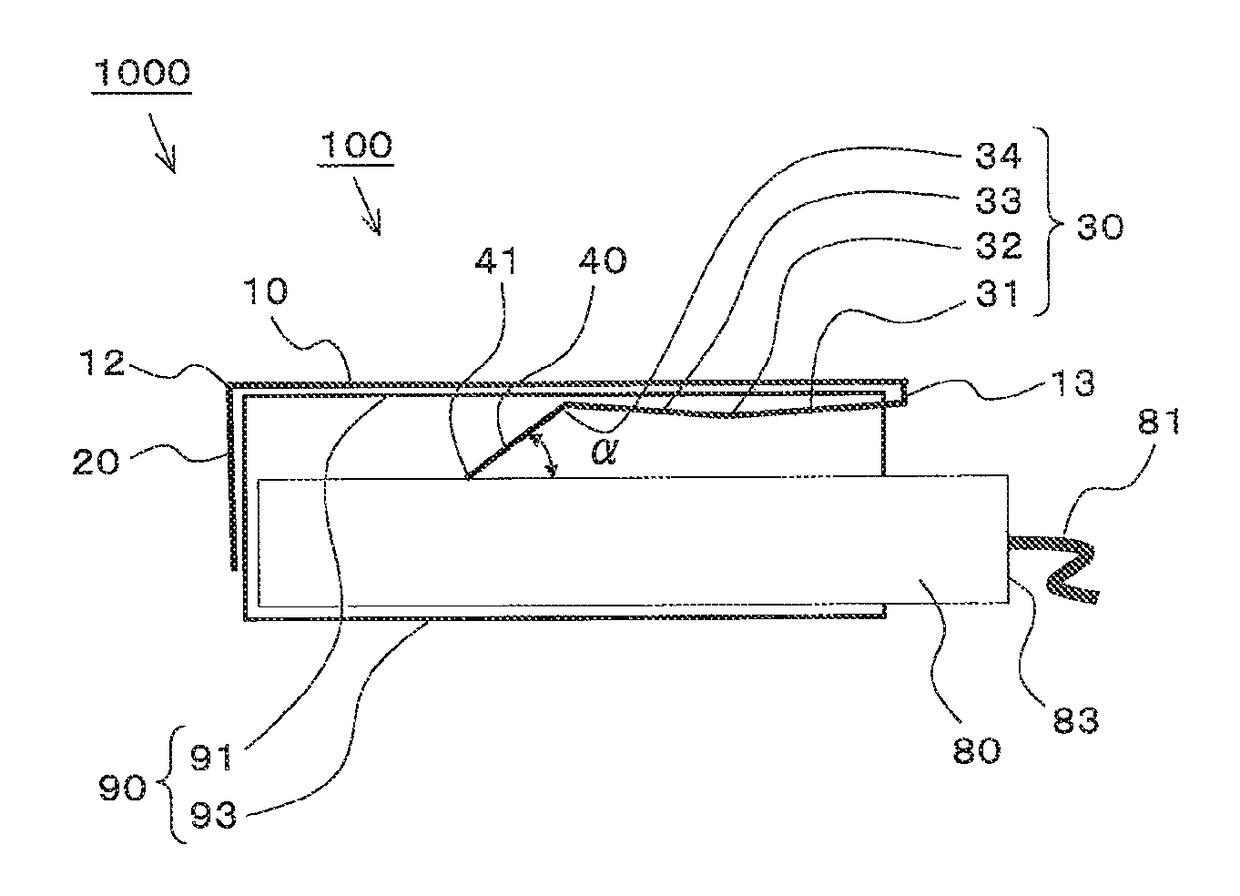

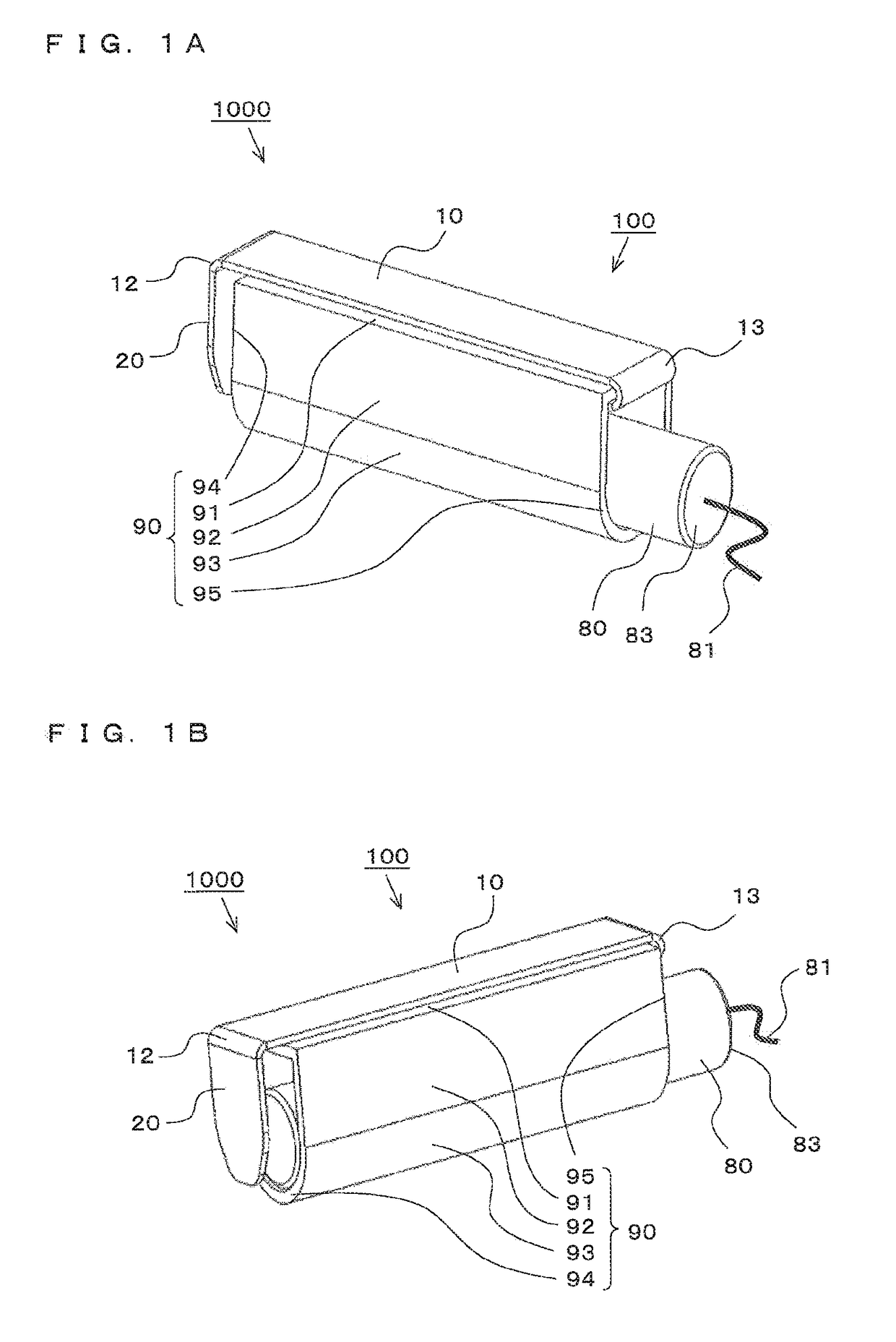

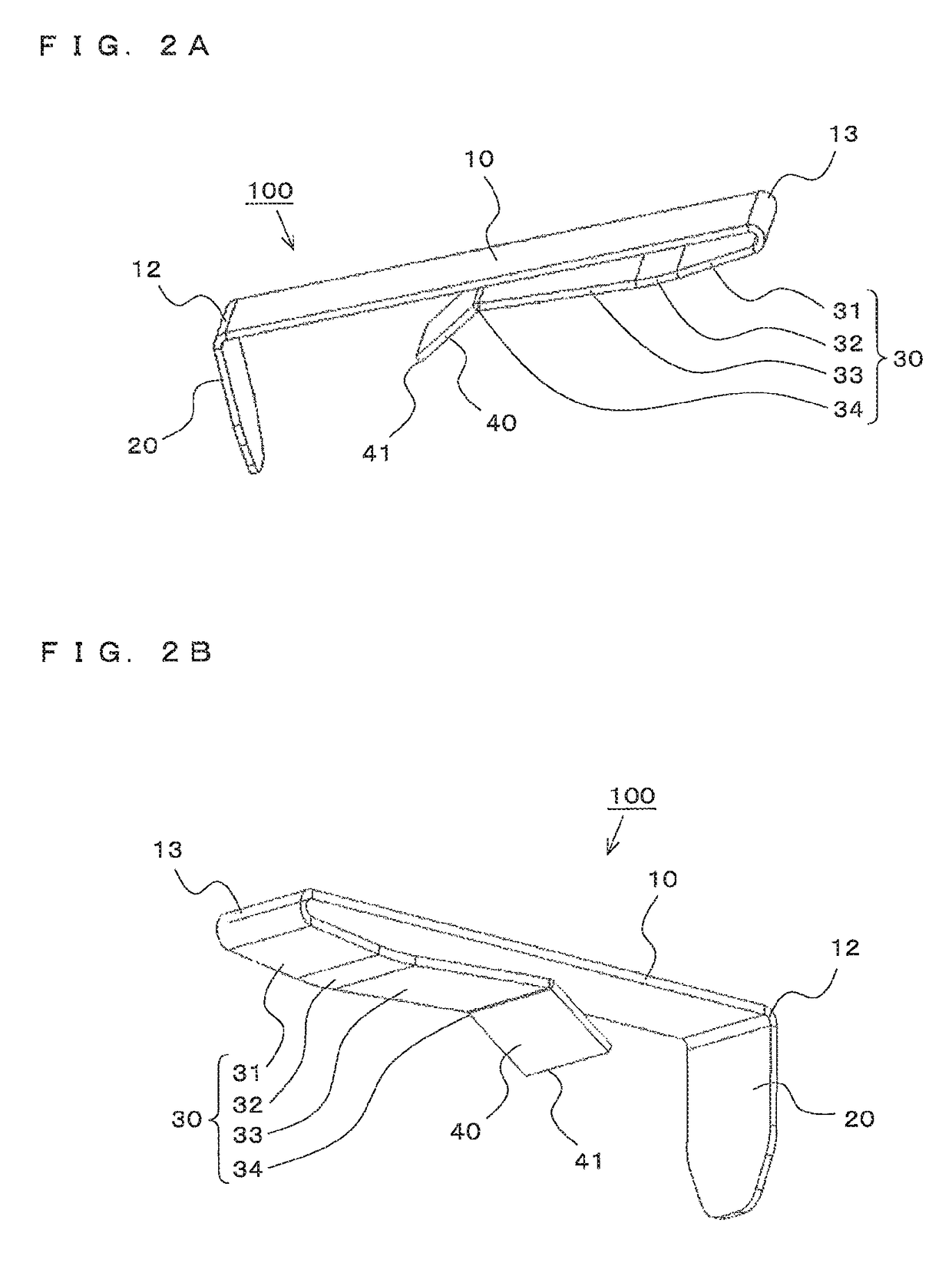

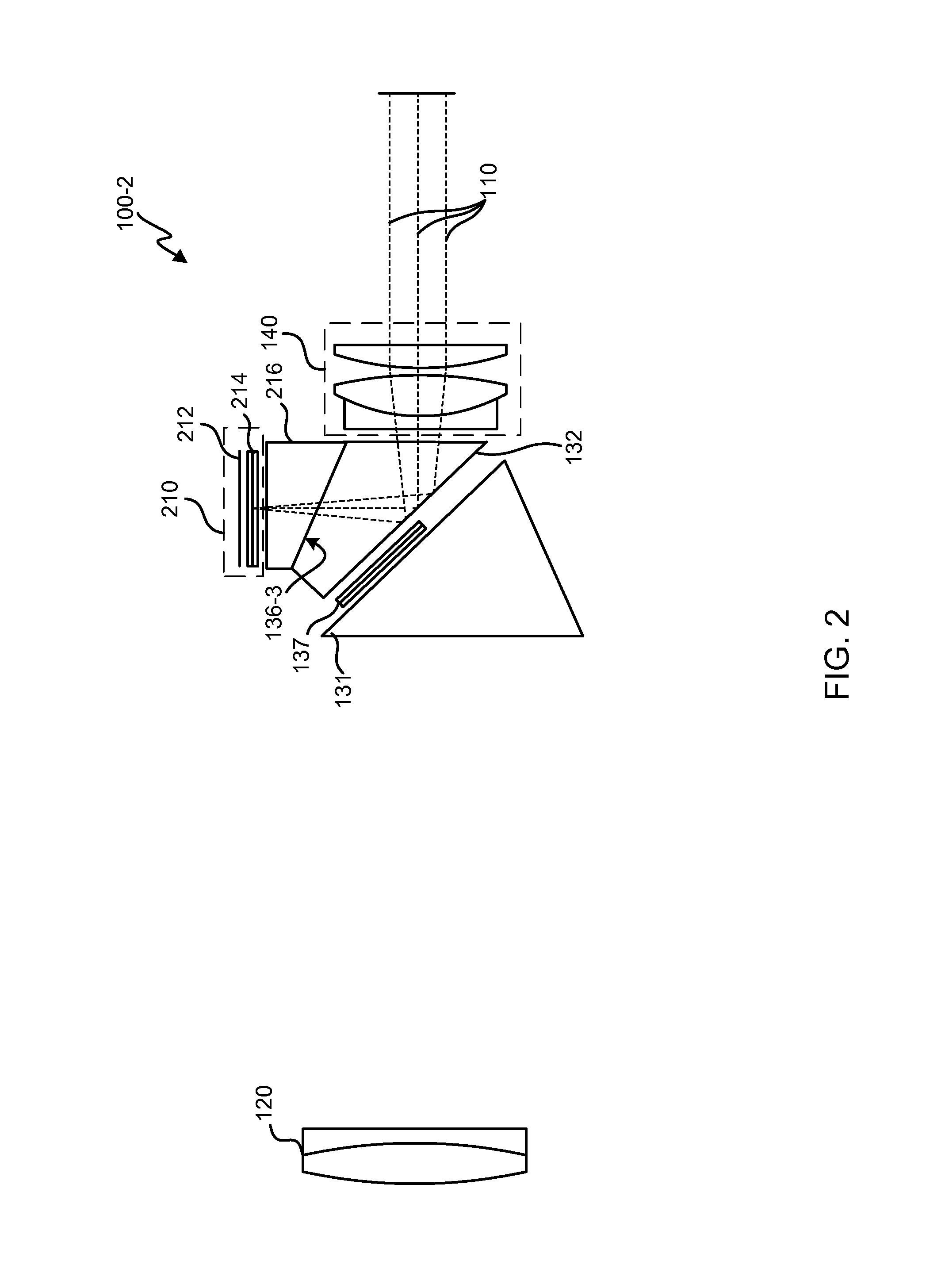

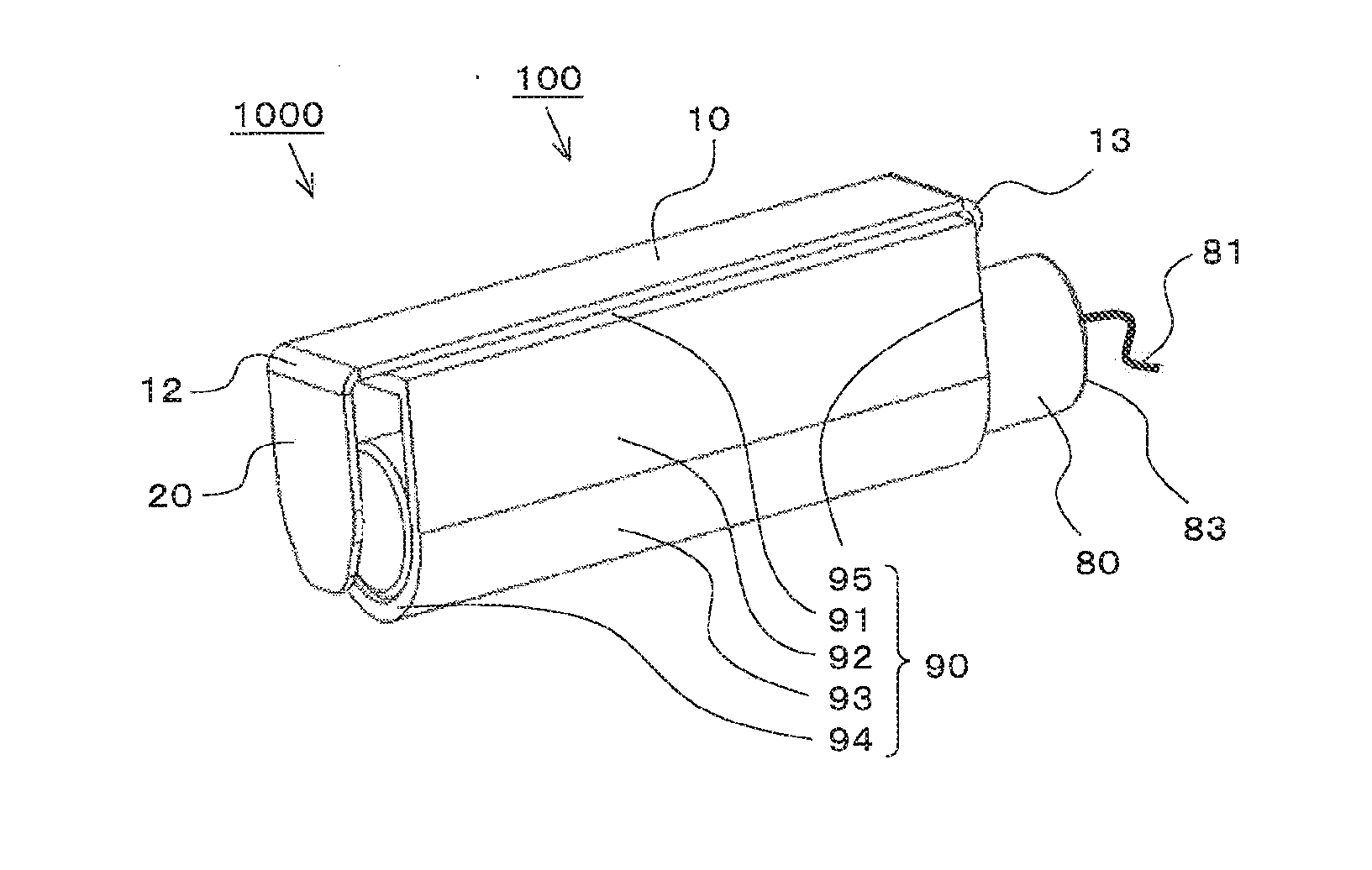

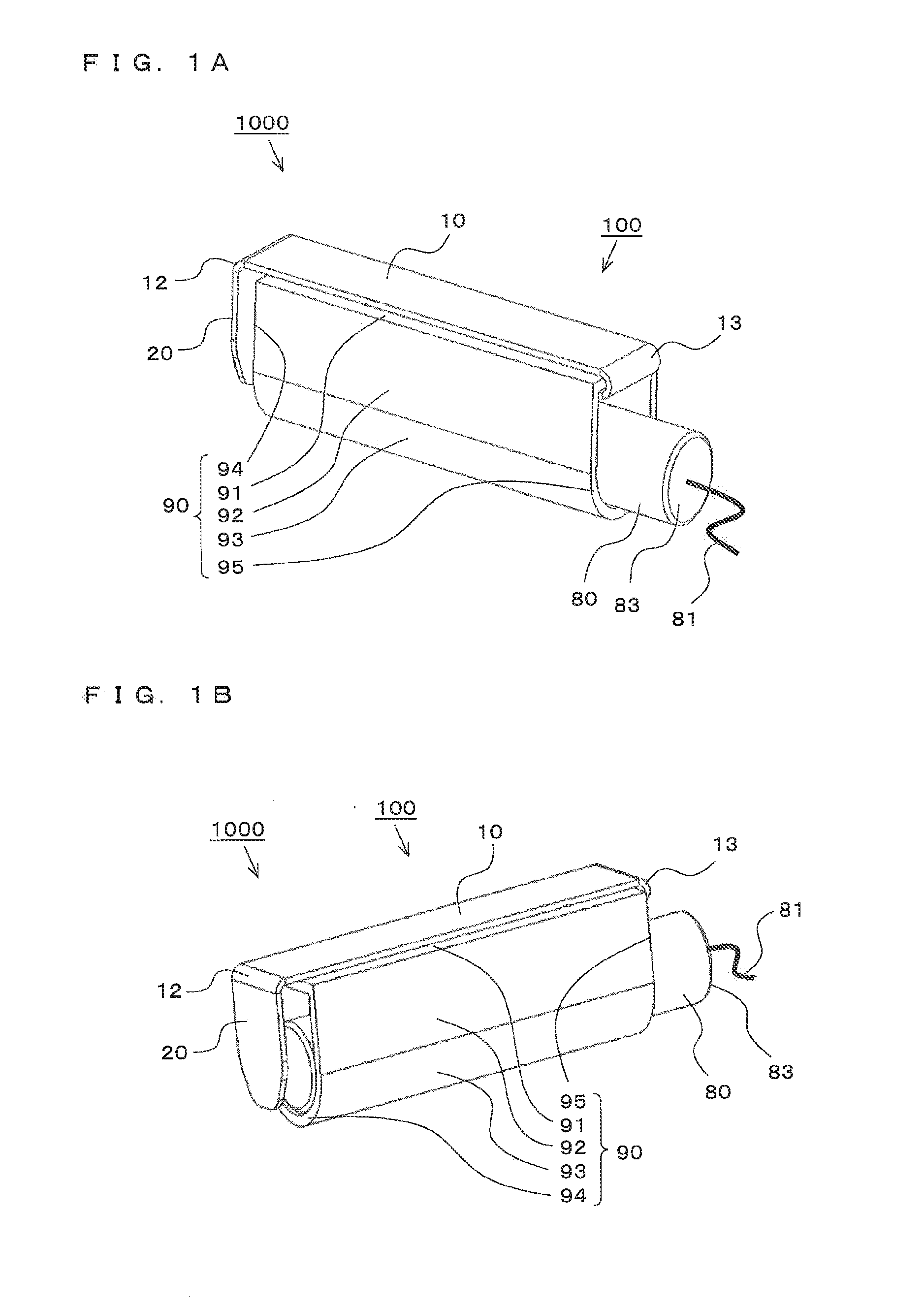

Thermistor fixing structure, thermistor removing method, and air-conditioning apparatus

InactiveUS9816867B2Easy to solveEasy to insertThermometer detailsMechanical apparatusAcute angleEngineering

Provided is a thermistor fixing structure capable of facilitating insertion of a thermistor into a temperature sensitive cylinder, and preventing the thermistor from easily dropping off the temperature sensitive cylinder. In a thermistor fixing structure (4000), a fixture (400) for pressing a thermistor (80) against an inner surface of a temperature sensitive cylinder (90) includes an inner bending section (20) formed at one end portion (12) of a longitudinal section (10) so as to function as a stopper for the thermistor (80) inserted into the temperature sensitive cylinder (90) from a cylinder insertion end (95), an outer bending section (50) formed at the one end portion (12) of the longitudinal section (10) so as to be opposed to a cylinder stop end (94), and an inner folding section (30) and an outer folding section (60) formed at another end portion (13) of the longitudinal section (10) so as to sandwich a cylinder top surface of the temperature sensitive cylinder (90). A side surface of the thermistor (80) is pressed at two points corresponding to an apex of a projecting portion (32) formed on the inner folding section (30) and a distal end (41) of a pressing section (40) formed continuously with the inner folding section (30), and a contact angle (α) formed between the pressing section (40) and the side surface of the thermistor (80) on the cylinder insertion end (95) side is an acute angle.

Owner:MITSUBISHI ELECTRIC CORP

Sound muffler and oxygen concentration device comprising the same

Provided is an expansion-chamber muffler as a downsized sound muffler while keeping a function of noise reduction, comprising:a tube (A) which supplies and evacuates a gas having a noise, wherein the tube (A) in the midway has a cavity with a cross-sectional area larger than that of the tube (A); andat least two or more ports for inflow or outflow of the gas on the lateral side of a tube (B) extending from the expansion-chamber muffler, on the opposite side of the noise source generating the noise.

Owner:TEIJIN LTD

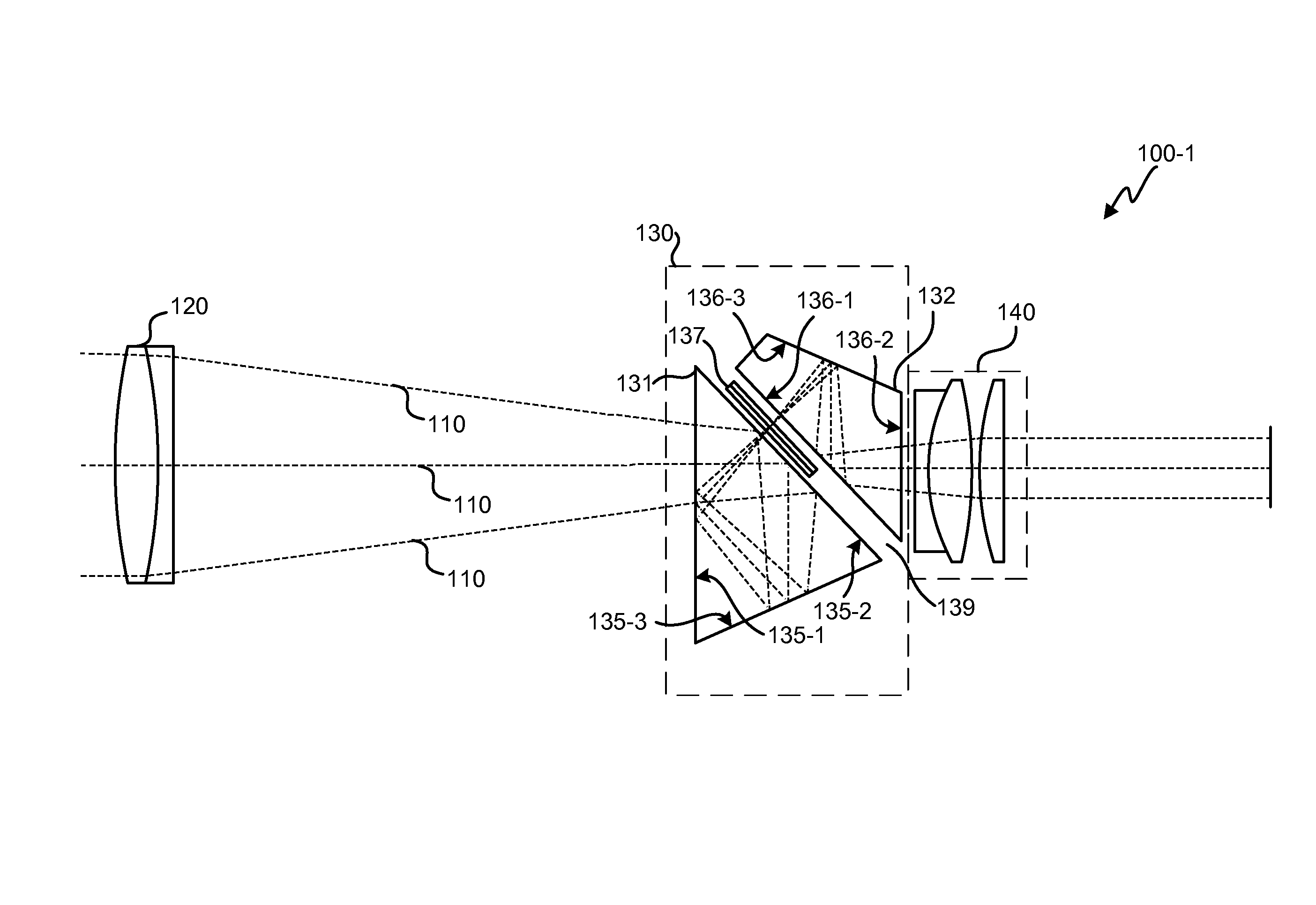

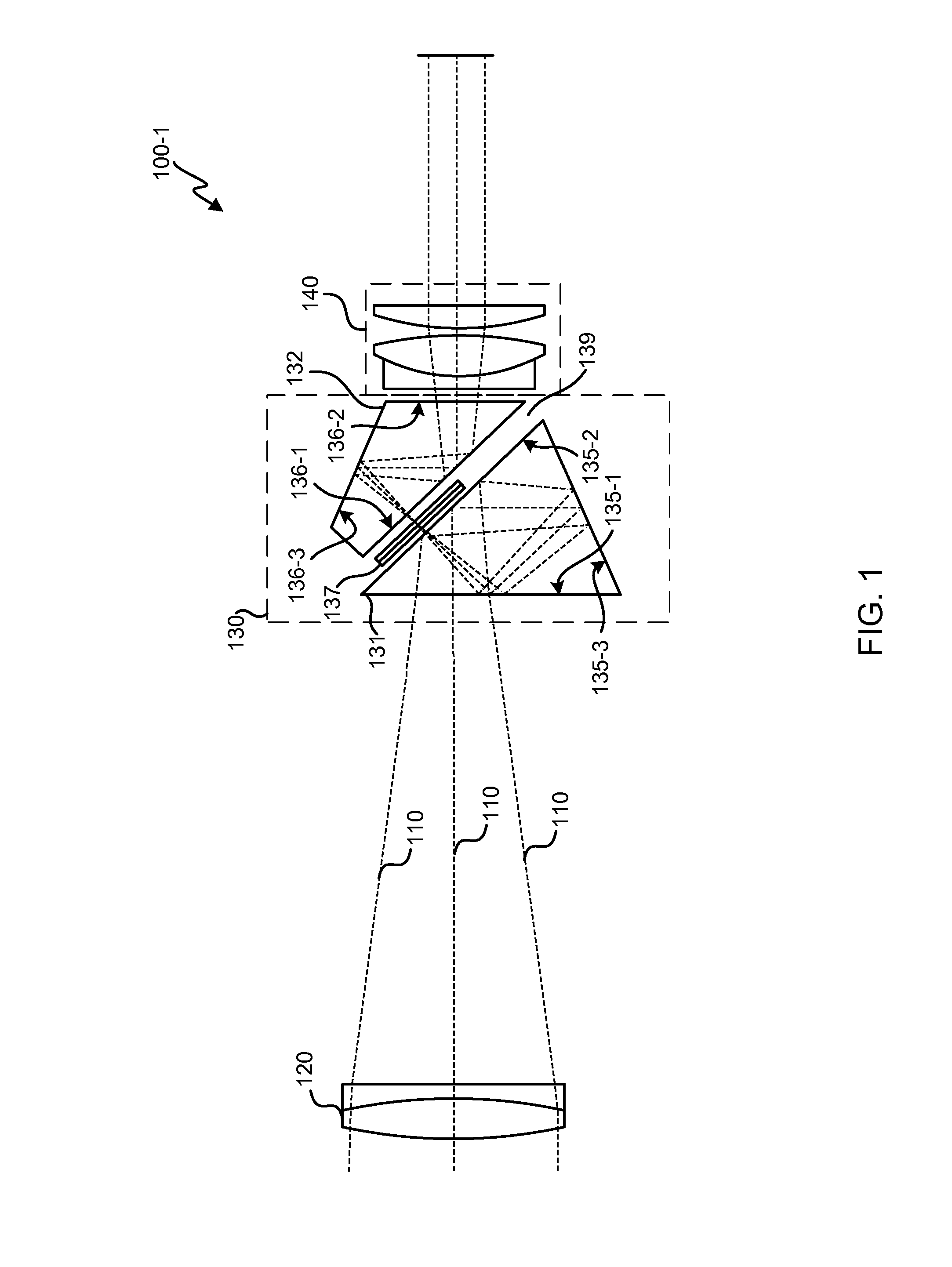

Integrated image erector and through-sight information display for telescope or other optical device

InactiveUS8988648B2Small and lightweightExtend battery lifeSighting devicesTelescopesLiquid-crystal displayDisplay device

Techniques are disclosed for creating optical systems and devices that provide through-sight information while enabling the optical systems and devices to maintain a small, lightweight form factor. According to certain embodiments of the invention, an optical assembly can include a liquid-crystal display (LCD) disposed between the two prism elements of a Schmidt-Pechan prism at a focal plane of the optical assembly. This allows the LCD to be used to display information by blocking light passing through the optical assembly. Additionally, a light-emitting display, such as a backlit LCD, light-emitting diode (LED) display, or organic LED (OLED) display, can be coupled at a surface of one of the two prism elements of the Schmidt-Pechan prism to provide additional information in low-light environments.

Owner:CUBIC CORP

Thermistor fixing structure, thermistor removing method, and air-conditioning apparatus

InactiveUS20150233769A1Easy to disassembleEasy to separateThermometer detailsMechanical apparatusAcute angleEngineering

Provided is a thermistor fixing structure capable of facilitating insertion of a thermistor into a temperature sensitive cylinder, and preventing the thermistor from easily dropping off the temperature sensitive cylinder. In a thermistor fixing structure (4000), a fixture (400) for pressing a thermistor (80) against an inner surface of a temperature sensitive cylinder (90) includes an inner bending section (20) formed at one end portion (12) of a longitudinal section (10) so as to function as a stopper for the thermistor (80) inserted into the temperature sensitive cylinder (90) from a cylinder insertion end (95), an outer bending section (50) formed at the one end portion (12) of the longitudinal section (10) so as to be opposed to a cylinder stop end (94), and an inner folding section (30) and an outer folding section (60) formed at another end portion (13) of the longitudinal section (10) so as to sandwich a cylinder top surface of the temperature sensitive cylinder (90). A side surface of the thermistor (80) is pressed at two points corresponding to an apex of a projecting portion (32) formed on the inner folding section (30) and a distal end (41) of a pressing section (40) formed continuously with the inner folding section (30), and a contact angle (α) formed between the pressing section (40) and the side surface of the thermistor (80) on the cylinder insertion end (95) side is an acute angle.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com