Intelligent high-speed down feather color selector

A color sorter and down technology, which is applied in the field of down processing, can solve the problems of dull color sorting, low efficiency, human eye damage, etc., and achieves the effect of facilitating popularization and utilization, solving low efficiency and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

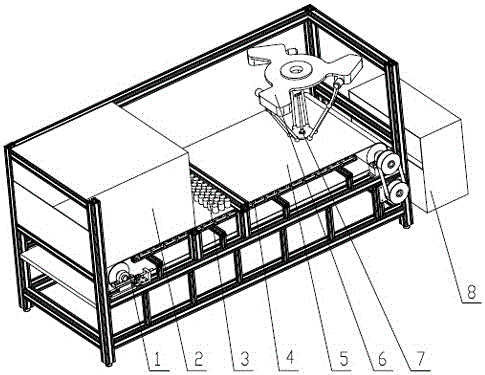

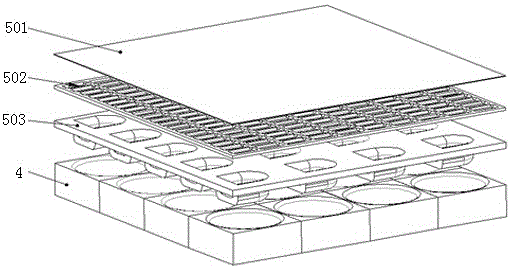

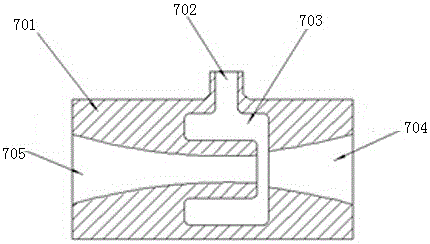

[0020] As shown in the figure, the intelligent high-speed down color sorter includes a down conveyor belt 5, and a roller 1 is provided at both ends of the down conveyor belt 5, and the roller 1 is connected to an external driving mechanism. The down conveyor belt 5 is sequentially divided into down-feeding section, detection section, sorting section and down-receiving section. Down supply box 2 is set above the down-loading section, detection lens array 3 is set above the detection section, and DELTA is set above the sorting section. The robot 6 and the DELTA robot 6 are provided with a sorting head 7, one side of the down section is provided with a down suction box 8, and a miniature frequency conversion fan 4 is provided under the down section, the detection section, the sorting section and the down section. The air volume of the micro frequency conversion fan 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com