Eddy type biomass particle gasification burner

A technology of biomass pellets and burners, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc. It can solve the problems of harmful gas pollution of the environment, inconvenient processing and manufacturing, and uncompact structure, and achieve low operating costs. , small size and weight, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

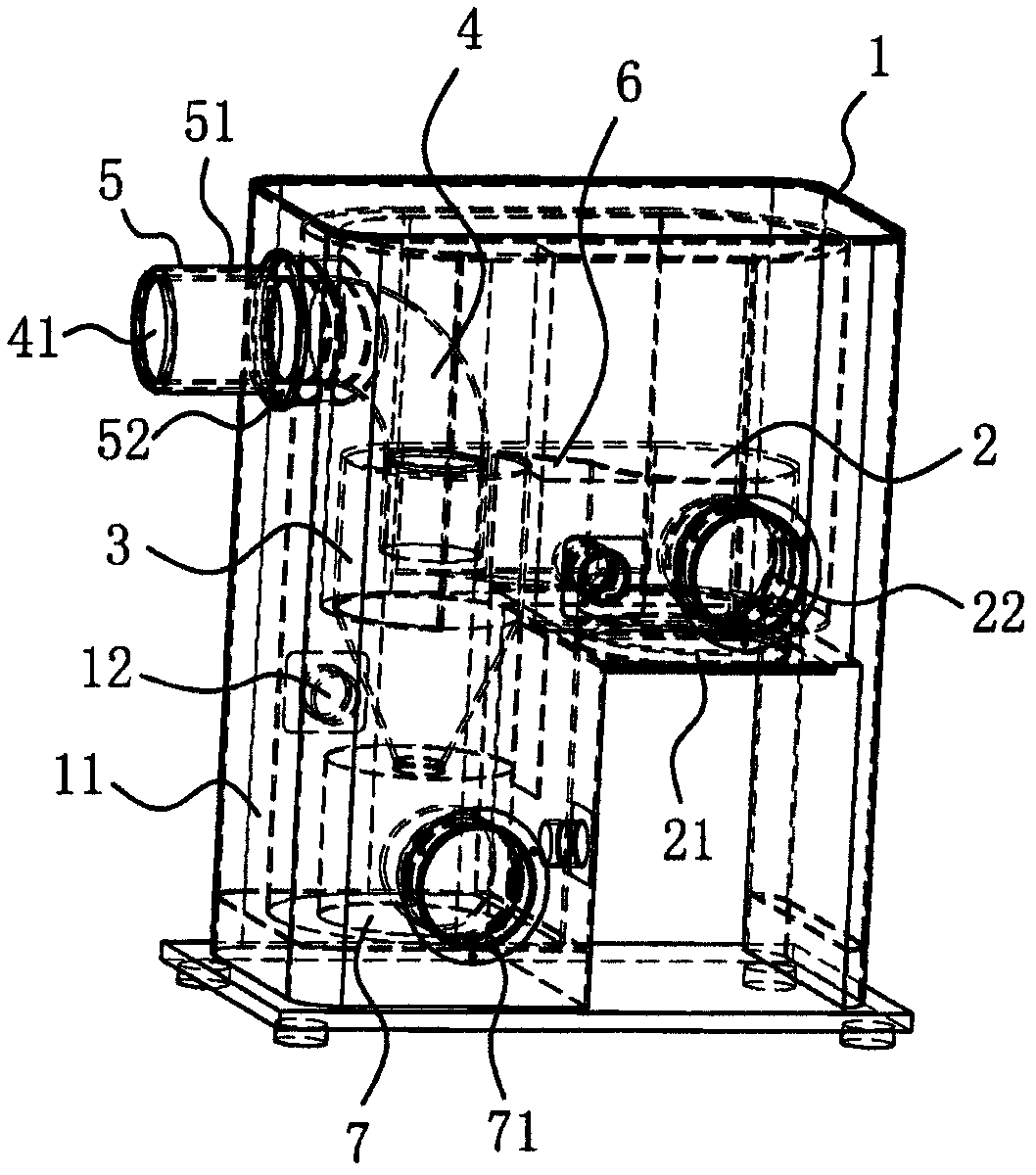

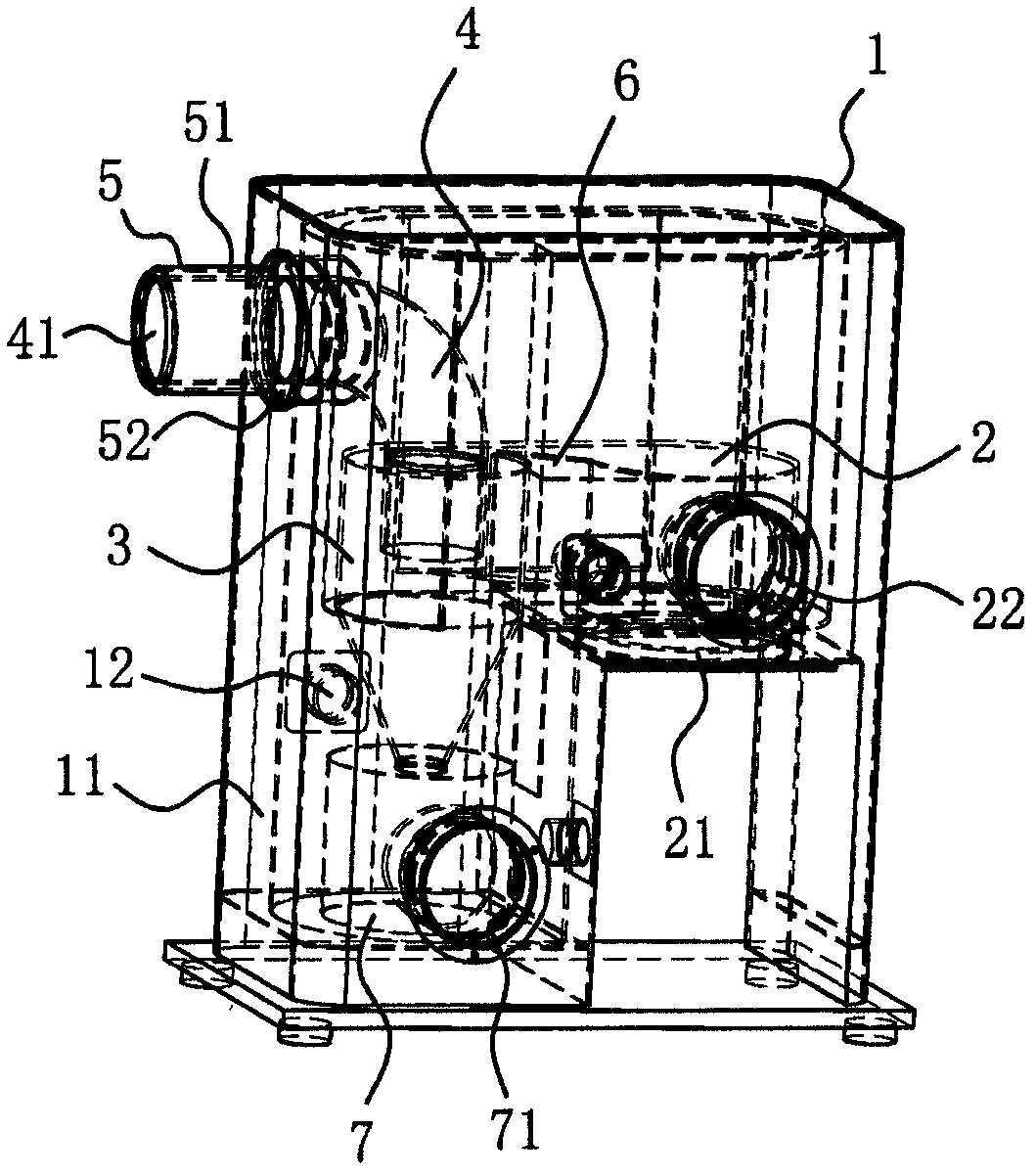

[0019] Such as figure 1 As shown, the biomass particle vortex gasification burner includes a housing 1 with an air chamber 11, a first combustion chamber 2 with a feed port 21 located in the housing 1, and a second combustion chamber communicated with the first combustion chamber 2. Two combustion chambers3. In this embodiment, the first combustion chamber 2 communicates with the second combustion chamber 3 through a square tapered flow passage 6 , and the square tapered flow passage 6 enters tangentially along the inner wall of the second combustion chamber 3 . After entering from the tangential direction, a vortex whirlwind is naturally formed in the second combustion chamber 3, so that the biomass material is gasified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com