A preparing method of a polymer Janus nanosheet PtBMA/PAM

A technology of polymers and nanosheets, applied in the field of preparation of polymer Janus nanosheets PtBMA/PAM, can solve the problems of complex methods, harsh conditions, and lack of universality, and achieve good application prospects and good emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

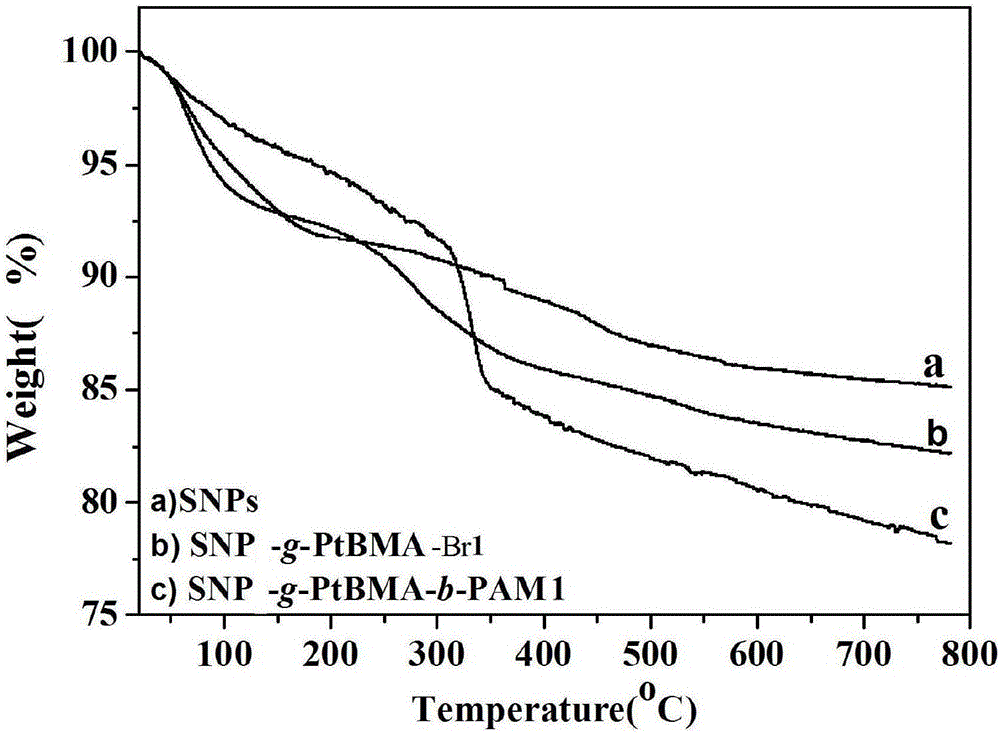

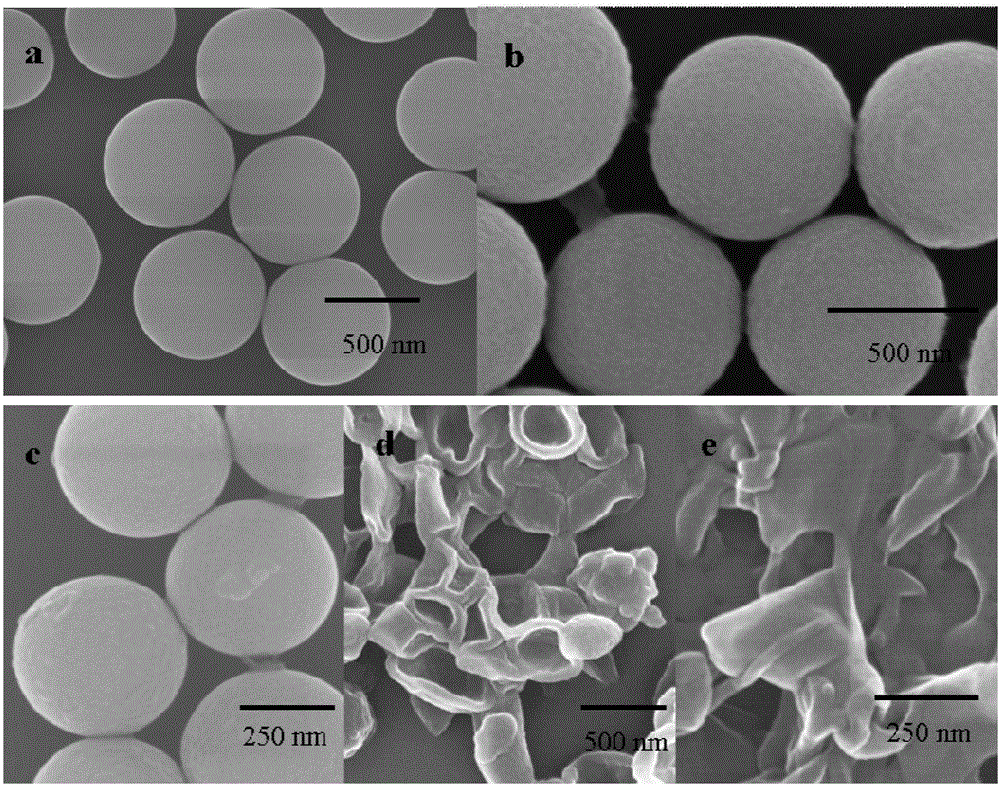

[0029] Example 1 Preparation of polymer Janus nanosheets PtBMA / PAM1

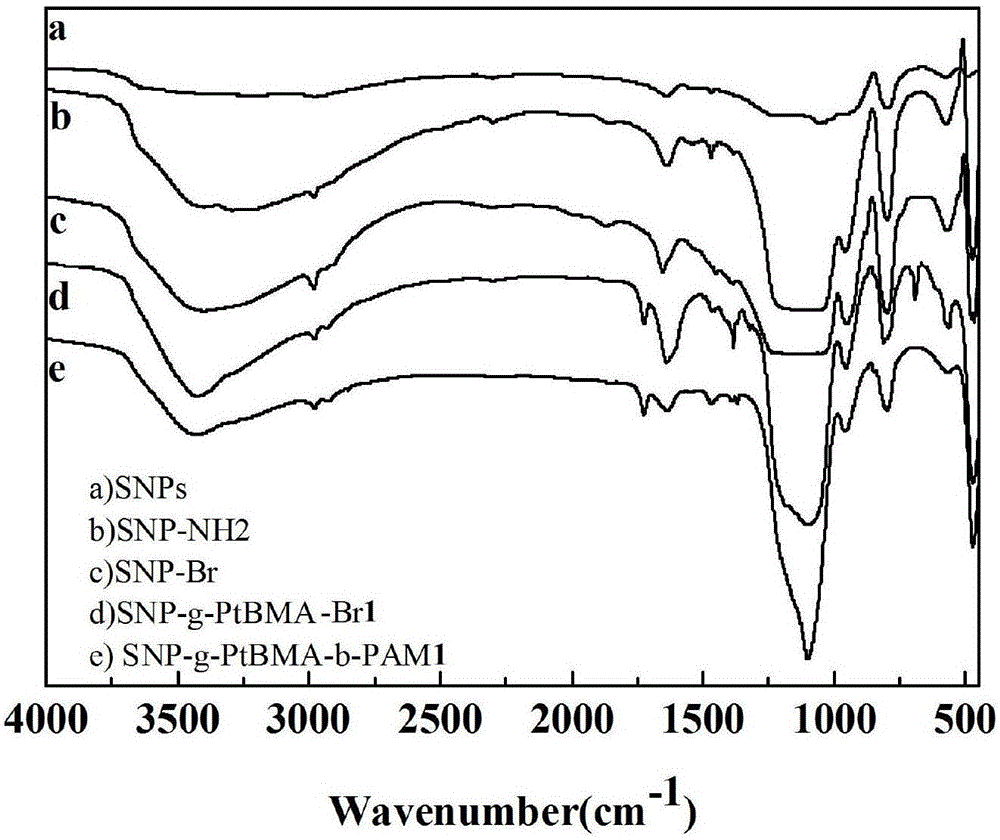

[0030] (1) Synthesis of SNP-Br

[0031] 1. Nano SiO 2 Preparation of microspheres (SNPs)

[0032] Weigh 42.6g of ethanol, 25g of 25% ammonia water, and 9.75g of water respectively, put them into a 250mL round bottom flask, and stir evenly. Mix 7.7g TEOS and 30g ethanol evenly, place in a dropping funnel, drop dropwise into a round bottom flask, and react at 35°C for 12 hours under magnetic stirring. After the reaction, the reaction mixture was centrifuged to remove the supernatant, and the white solid was washed three times with a mixed solution of ethanol and water with a volume ratio of 9:1 to obtain nano-SiO 2 microspheres (SNPs). The product was put into a vacuum oven for later use. The synthetic route is as follows:

[0033]

[0034] 2. Nano SiO 2 Microspheres (SNPs) surface amino modification (SNP-NH 2 ):

[0035]1.5g of SNPs was added to 50mL of anhydrous toluene, and ultrasonicated until ...

Embodiment 2

[0058] Example 2 Preparation of polymer Janus nanosheets PtBMA / PAM2

[0059] (1) Synthesis of SNP-Br: with Example 1

[0060] (2) Synthesis of SNP-g-PtBMA-Br2

[0061] After ultrasonically dispersing 0.1 g of SNP-Br in 8 mL of dry DMF, transfer to a polymerization tube, add 0.75 g tBMA, 0.15 g EGDMA, 36 μL of Me 6 TREN, mix well, freeze with liquid nitrogen, evacuate, melt, cycle liquid nitrogen freeze-vacuum-thaw three times, add catalyst 30mg CuBr in nitrogen atmosphere, and perform another cycle of liquid nitrogen freeze-vacuum-thaw, Seal the tube under vacuum. React at 73°C for 12 hours. The reaction was terminated by exposure to air. Wash by centrifugation, remove the supernatant, and dry the solid to obtain SNP-g-PtBMA-Br2.

[0062] (3) Synthesis of SNP-g-PtBMA-b-PAM2

[0063] After ultrasonically dispersing 0.1 g of SNP-g-PtBMA-Br2 in 8 mL of dry DMF, transfer to a polymerization tube, add 0.6 g of AM, 24 mg of PMDETA, mix well, freeze with liquid nitrogen, vacuum...

Embodiment 3

[0066] Example 3 Preparation of polymer Janus nanosheets PtBMA / PAM3

[0067] (1) Synthesis of SNP-Br: with Example 1

[0068] (2) Synthesis of SNP-g-PtBMA-Br3

[0069] After ultrasonically dispersing 0.1 g of SNP-Br in 8 mL of dry DMF, transfer to a polymerization tube, add 1.5 g of tBMA, 0.12 g of EGDMA, 36 μL of Me 6 TREN, mix well, freeze with liquid nitrogen, evacuate, melt, cycle liquid nitrogen freeze-vacuum-thaw three times, add catalyst 30mg CuBr in nitrogen atmosphere, and perform another cycle of liquid nitrogen freeze-vacuum-thaw, Seal the tube under vacuum. React at 73°C for 24 hours. The reaction was terminated by exposure to air. Wash by centrifugation, remove the supernatant, and dry the solid to obtain SNP-g-PtBMA-Br3.

[0070] (3) Synthesis of SNP-g-PtBMA-b-PAM3

[0071] After ultrasonically dispersing 0.1 g of SNP-g-PtBMA3 in 8 mL of dry DMF, transfer to a polymerization tube, add 1.5 g of AM, 48 mg of PMDETA, mix well, freeze with liquid nitrogen, evac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap