Blast furnace air supply belly pipe avoiding small sleeve abrasion and machining assembling method of blast furnace air supply belly pipe

An assembly method and a technology of direct blowing pipes, which are applied in the direction of the tuyere, can solve the problems of easy wear and tear, and achieve the effects of extending the period of scheduled maintenance, reducing the consumption of spare parts, and reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

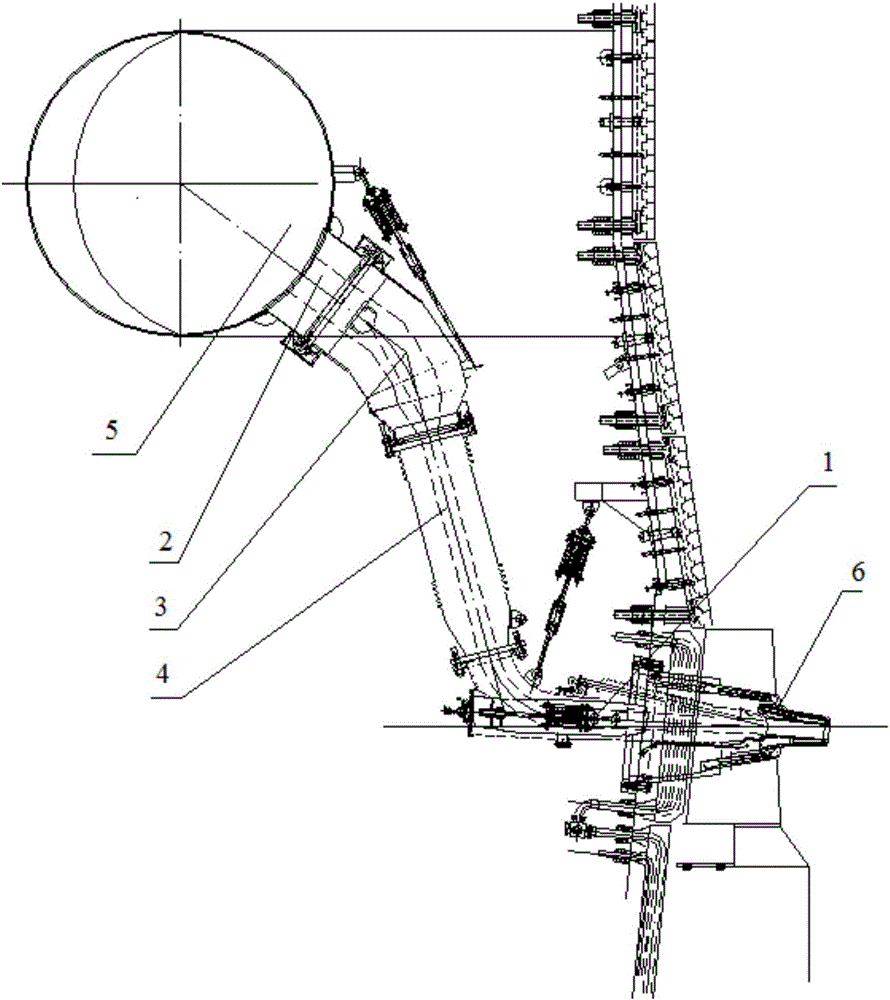

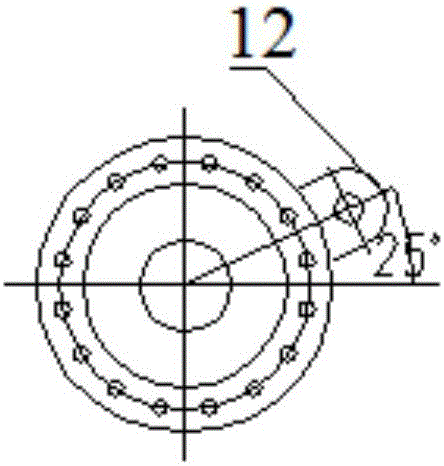

[0042] combine Figure 1-6 , a blast furnace air supply straight blowpipe for avoiding wear and tear of the small sleeve, comprising a straight blowpipe 1, a gun holster 12 and a small sleeve 6, and also includes a flange 7 and a gun holster protective sleeve 121, wherein one end of the straight blowpipe 1 is connected to an elbow, Straight blowpipe 1 other end is connected with small cover 6, and straight blowpipe 1 is provided with gun holster 12, and gun holster 12 is inserted in the straight blowpipe 1, and the extension line of gun holster 12 intersects with the center line of small sleeve entrance.

[0043] The outside of the holster 12 is provided with a holster protective cover 121 , and the holster protective cover 121 plays the role of fixing and protecting the holster 12 .

[0044] In view of the technological standard requirements of the blast furnace itself, the coal injection gun is inserted into the holster 12, the coal injection gun is inserted into the small s...

Embodiment 2

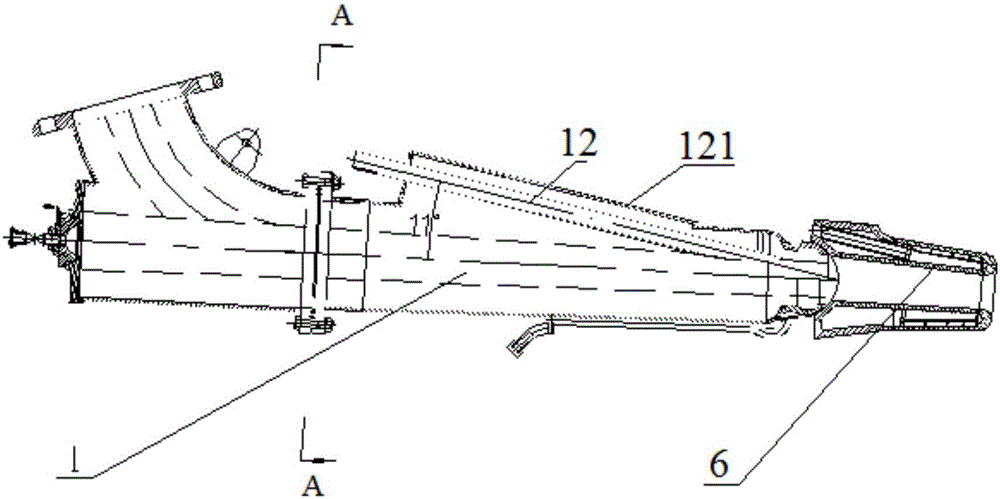

[0050] A blast furnace air supply direct blowpipe avoiding small sleeve wear in this embodiment is the same as embodiment 1, a processing and assembling method for blast furnace air supply direct blowpipe avoiding small sleeve wear, including the following steps:

[0051] A, according to a kind of blast furnace air-supply blowpipe that avoids wear and tear of small cover described above, carry out rolling pipe and make straight blowpipe 1, form the shape of bell mouth;

[0052] B, cut off a position to form the gun holster 12 on the straight blow pipe 1, fix two ribs into the gun holster 12, and weld it on the straight blow pipe 1;

[0053] C, weld the holster protective cover 121 on the straight blowpipe 1, and form a side cavity between the holster 12 and the holster protective cover 121;

[0054] The centerline of the holster 12 of the coal injection gun is in the horizontal plane, and the angle between the centerline of the holster 12 of the coal injection gun and the cent...

Embodiment 3

[0060] A kind of blast furnace air supply direct blowpipe and its processing and assembling method of avoiding small sleeve wear of this embodiment are the same as embodiment 1, and the main technical scheme of this embodiment is: change the angle of the lance path of straight blowpipe 1 spray gun (for coal powder injection) , when coal powder is sprayed into the blast furnace through the spray gun and passes through the small tuyere cover (i.e. the small cover 6), avoid coal dust from washing the small tuyere cover, so as to achieve the purpose of prolonging the service life of the small tuyere cover. It mainly includes the following technical points: reduce the angle between the center line of the coal injection lance and the center line of the straight blowing pipe from the original 11 degrees to 8 degrees; reduce the angle between the center line of the coal injection lance and the horizontal plane from the original The 25 degrees of the coal injection gun are reduced to 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com