Underneath type arc extinguishing structure of small-sized sealed electromagnetic relay bottom plate

A technology for sealing electromagnetic and relays, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as the influence of relay pull-in and release performance, accelerated relay life loss, and poor contact reliability, etc., to achieve improved Life and overload resistance, arc elimination, and the effect of reducing ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

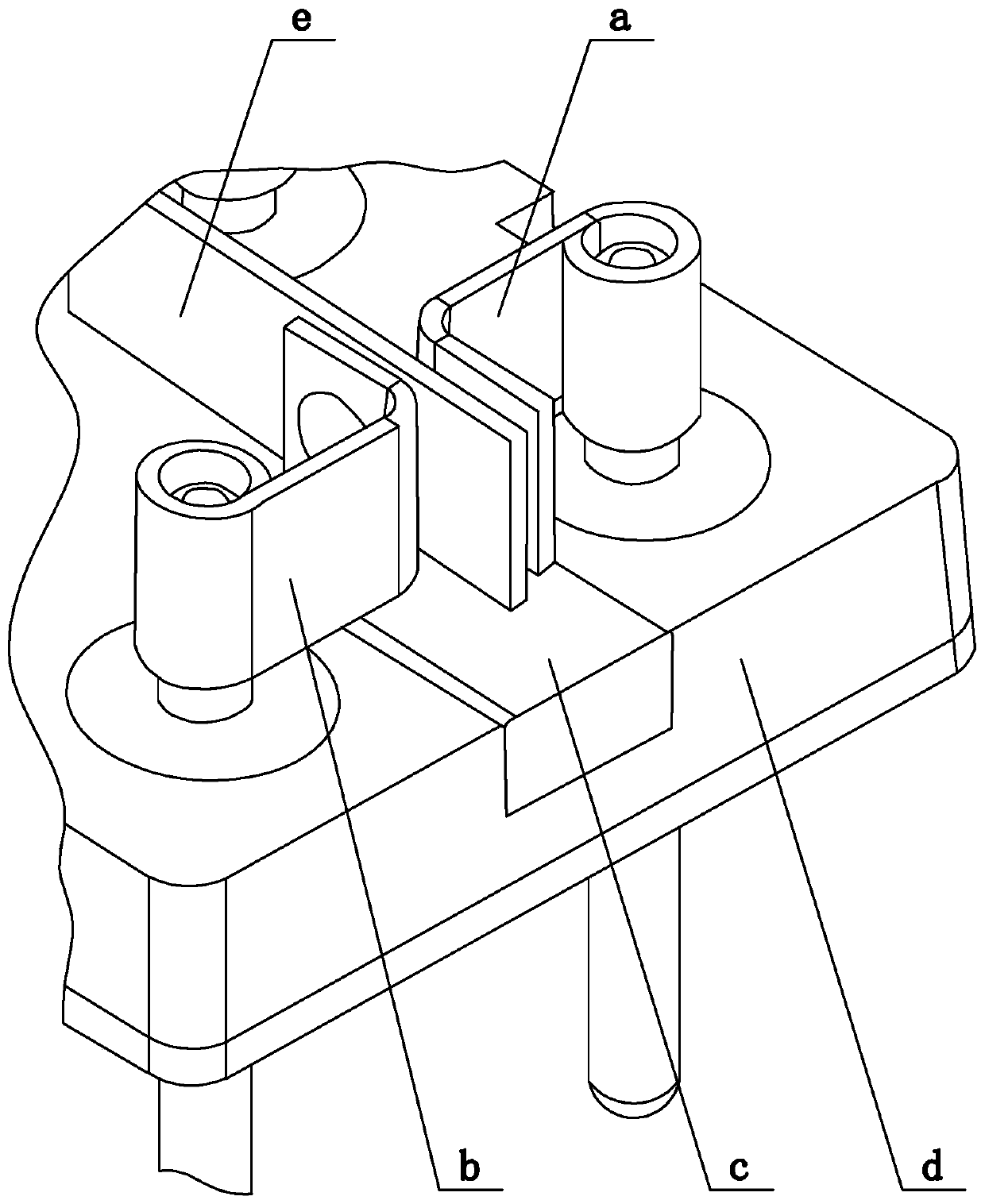

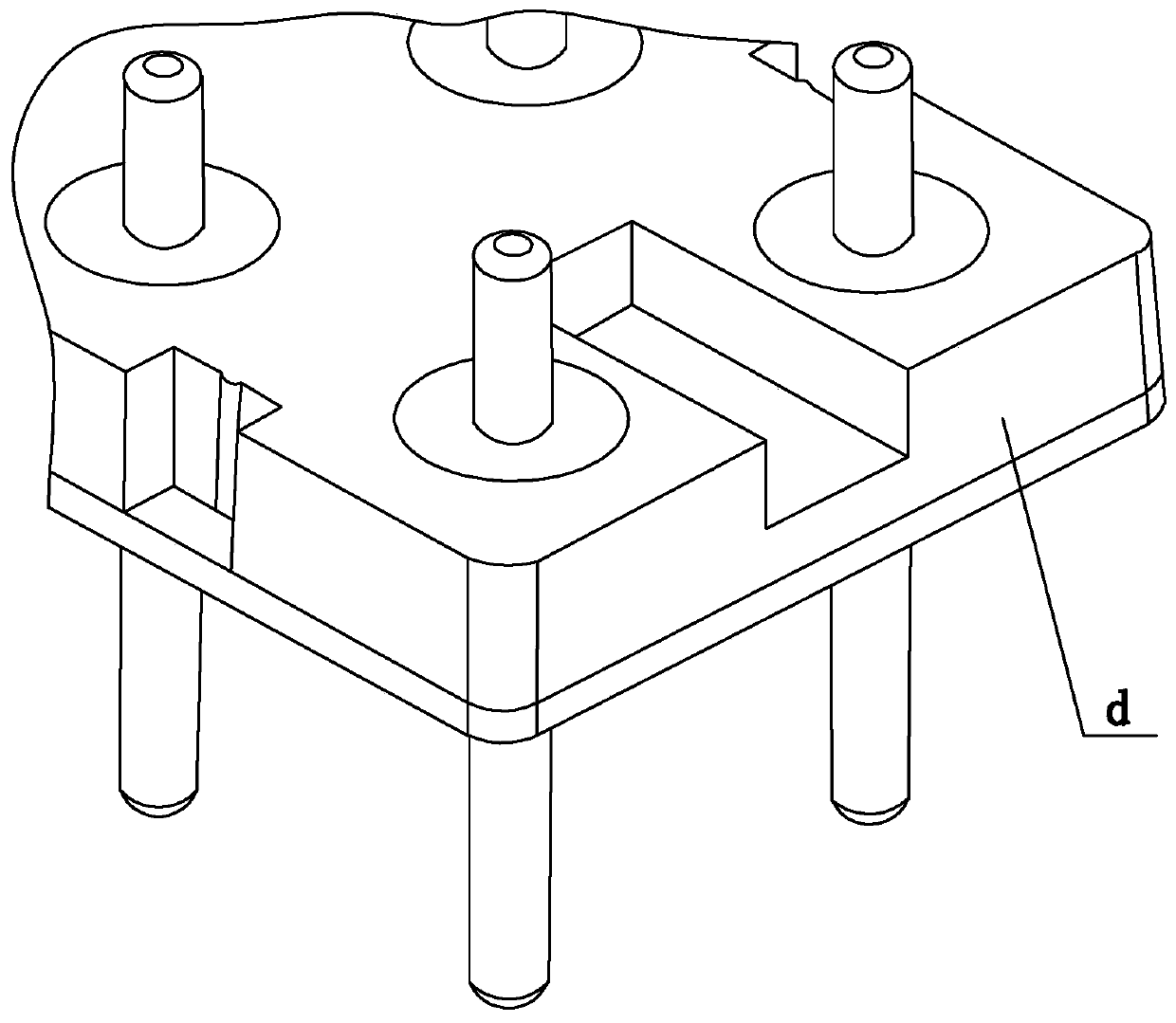

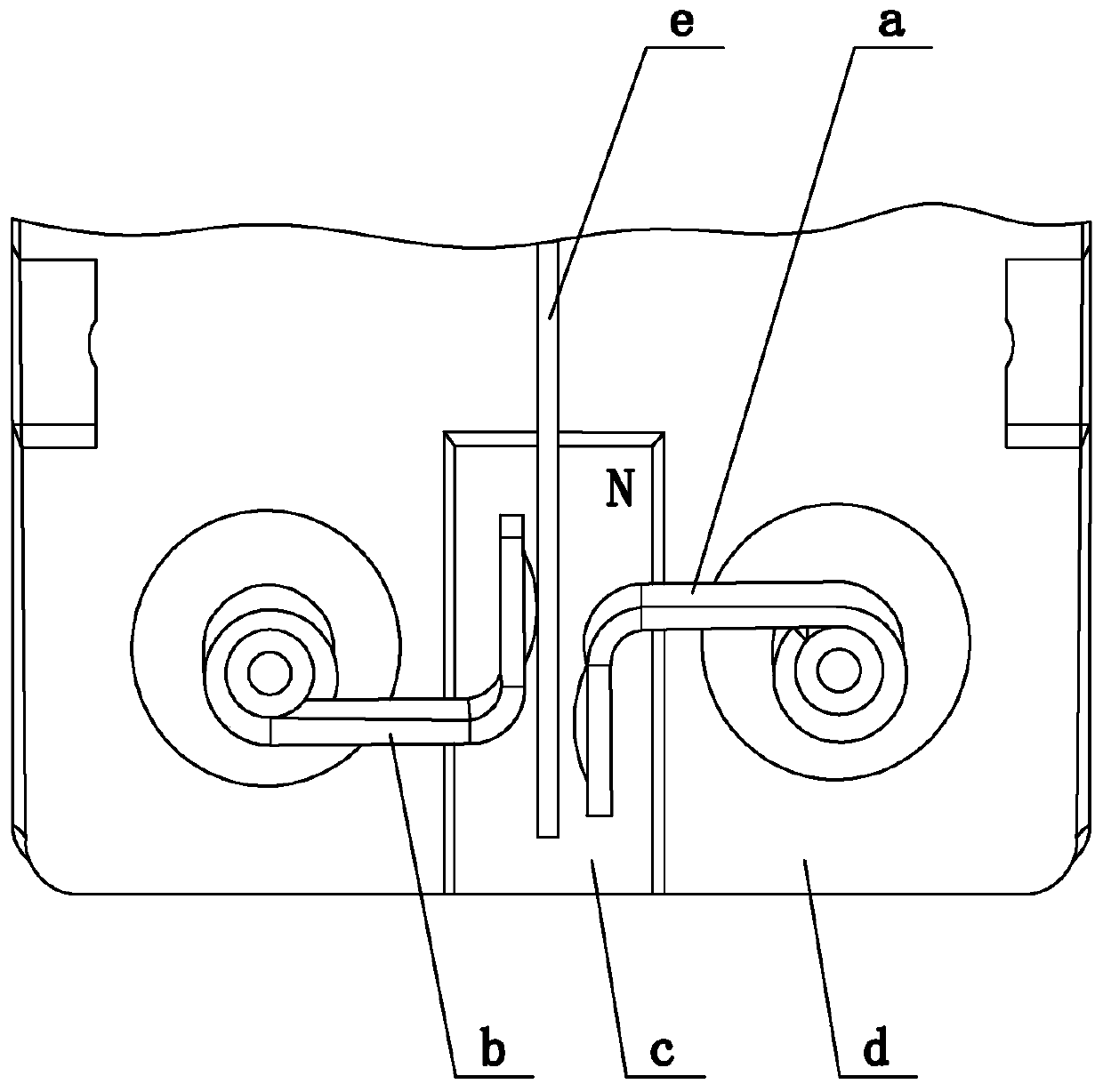

[0016] Specific implementation mode one: as figure 1 , figure 2 As shown, this embodiment discloses a small-sized sealed electromagnetic relay bottom plate arc extinguishing structure, including a permanent magnet c and a contact spring group; the contact spring group is vertically arranged on the upper surface of the bottom plate d of the electromagnetic relay, and the curled end of the contact spring group It is welded and fixed on the lead-out rod, and the lead-out rod and the glass insulator are sintered and fixed on the bottom plate d; one end of the upper surface of the bottom plate d is provided with a long groove, and the permanent magnet c is embedded in the long groove and fixed by glue (permanent The magnet c needs to be magnetized and stabilized before being embedded in the long slot), and the upper surface of the permanent magnet c is flush with the upper surface of the bottom plate d (so that the permanent magnet c can be stably fixed in the long slot, and it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com